Spun-bonded polypropylene board and manufacturing method thereof

A technology of polypropylene board and manufacturing method, which is applied in the direction of chemical instruments and methods, layered products, synthetic resin layered products, etc., can solve the problems of poor impact strength, low burst resistance, weak tensile strength, etc., and achieve High pass rate, extended service life, material saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

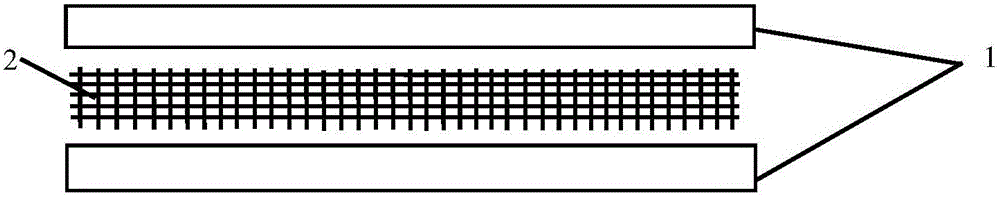

[0032] Now refer to figure 1 , 2 And the specific embodiment specifically sets forth the present invention:

[0033] refer to figure 1 , a spun-bonded polypropylene board in this embodiment, comprising a PP plastic board 1 and a chemical fiber mesh layer 2, characterized in that: the chemical fiber mesh layer 2 has a mesh fiber structure, and the PP plastic board 1 is two layer, the chemical fiber grid layer 2 is located between two layers of PP plastic boards 1, and the chemical fiber grid layer 2 and the PP plastic board 1 are connected by heat fusion.

[0034] The PP plastic board 1 contains 80% polypropylene, 15% polyethylene, 3% POE and 2% masterbatch.

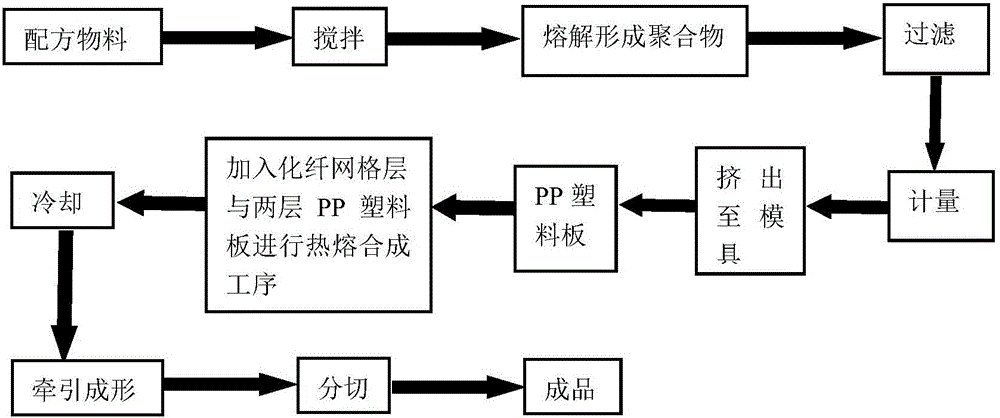

[0035] refer to figure 2 , a manufacturing method of spun-bonded polypropylene board, is characterized in that: comprising the following steps

[0036] a) Extrusion equipment A is provided in one direction of the overall main equipment. In the extrusion equipment A, polypropylene particles, polyethylene particle raw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com