Glass melting line

A glass melting and assembly line technology, applied in glass furnace equipment, glass manufacturing equipment, manufacturing tools, etc., can solve the problems of low degree of continuous operation, high glass breakage rate, incomplete glass melting and forming, etc., to achieve visual operation, Effects of strengthening safety, ensuring various indicators and product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

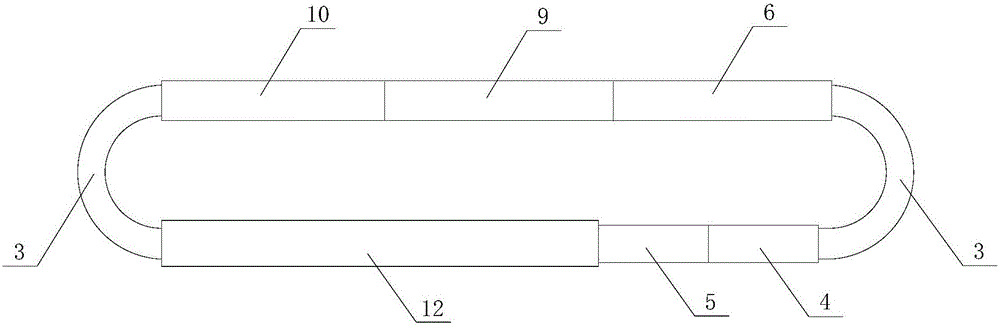

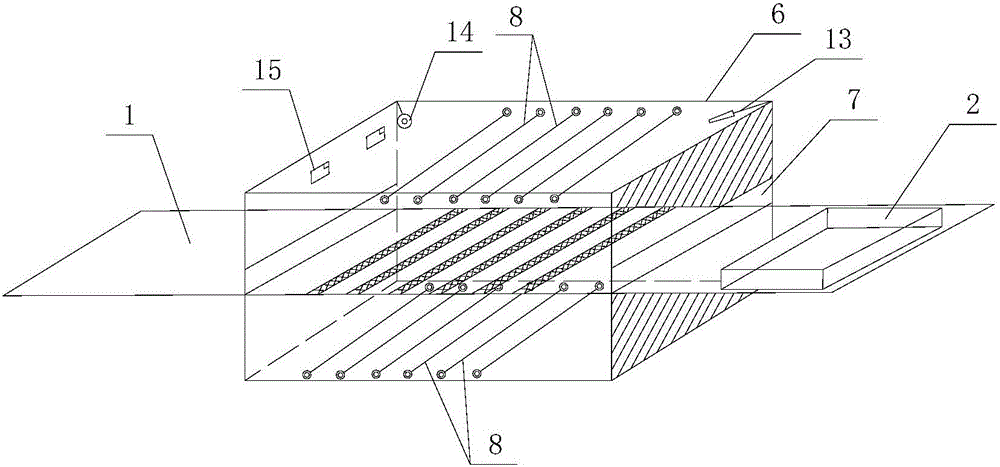

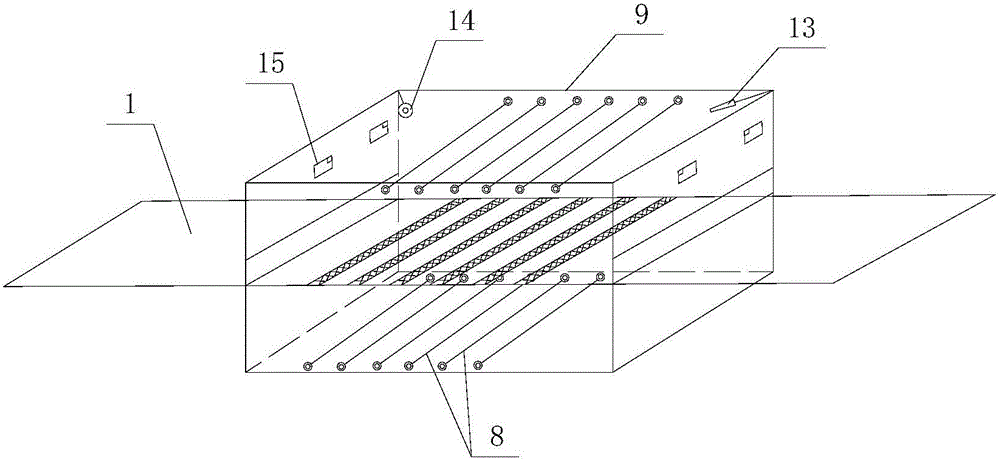

[0026] Such as Figures 1 to 4 As shown, a glass melting line includes a box body and a transmission mesh belt 1. The transmission mesh belt 1 is set through the box body. The transmission mesh belt 1 is provided with a mold 2 that moves with the transmission mesh belt 1. The transmission mesh belt 1 The ends are closed, and the two ends of the transmission mesh belt 1 are respectively provided with turning parts 3;

[0027] Loading and unloading area, the loading and unloading area is located outside the box, the loading and unloading area is divided into two parts: loading area 4 and unloading area 5, loading area 4 is located at the head end of transmission mesh belt 1, and unloading area 5 is located 1, the loading area 4 is connected with the unloading area 5;

[0028] Preheating zone 6, the preheating zone 6 is located in the box, the preheating zone 6 is connected with the loading zone 4, the entrance and exit of the preheating zone 6 are respectively provided with fla...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com