Environment-friendly low-drying-shrinkage crack-resistant casting waste sand concrete

An environmentally friendly casting waste sand technology, which is applied in the field of building materials, can solve the problems of reducing the service life of concrete structures and aggravating the deterioration of concrete, and achieve the effects of reducing dry shrinkage and cracking sensitivity, expanding the scope of use, and reducing surface tension.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Calculated by weight, it includes 340 parts of cement, 60 parts of rice husk ash, 728 parts of fine aggregate, 1092 parts of coarse aggregate, 7.8 parts of shrinkage reducing agent, 4 parts of water reducing agent and 180 parts of water.

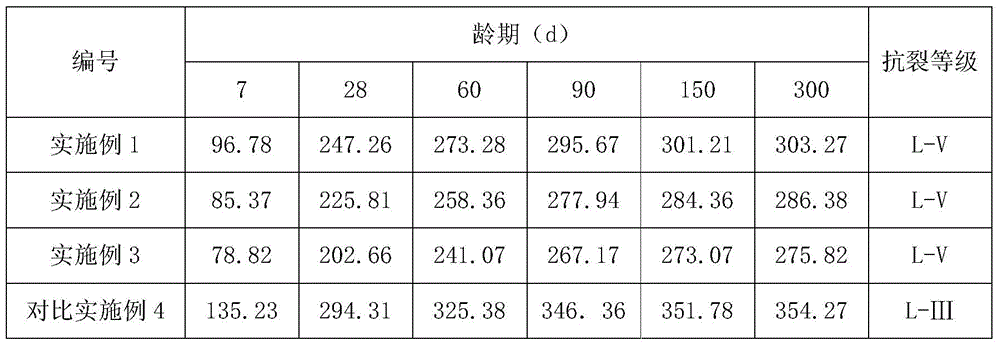

[0027] Performance testing: The compressive strength of concrete at 28 days is 47.2MPa, and its crack resistance grade and drying shrinkage value at different ages are shown in Table 1.

Embodiment 2

[0029] Calculated by weight, it includes 350 parts of cement, 70 parts of rice husk ash, 725 parts of fine aggregate, 1080 parts of coarse aggregate, 8 parts of shrinkage reducing agent, 4.6 parts of water reducing agent and 168 parts of water.

[0030] Performance testing: The compressive strength of concrete at 28 days is 52.9MPa, and its crack resistance grade and drying shrinkage value at different ages are shown in Table 1.

Embodiment 3

[0032] Calculated by weight, it includes 360 parts of cement, 80 parts of rice husk ash, 722 parts of fine aggregate, 1084 parts of coarse aggregate, 8.5 parts of shrinkage reducing agent, 5.2 parts of water reducing agent and 154 parts of water.

[0033] Performance testing: The compressive strength of concrete at 28 days is 57.7MPa, and its crack resistance grade and drying shrinkage value at different ages are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com