Trace initiating explosive type industrial nonel detonator

A technology of detonators and detonators, applied in detonators, offensive equipment, etc., can solve the problems of reducing the amount of detonators used and high costs, and achieve the effects of reducing the harm to workers' health, reducing pollution, and reducing consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

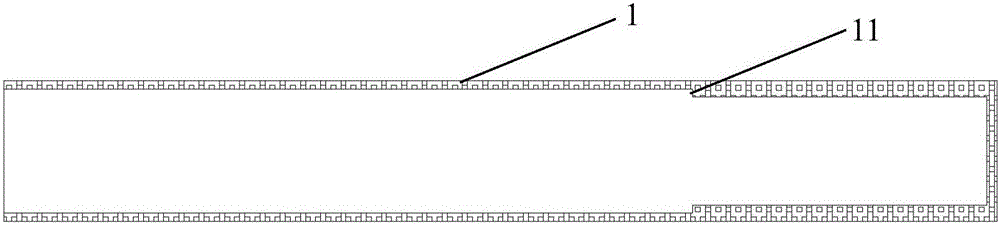

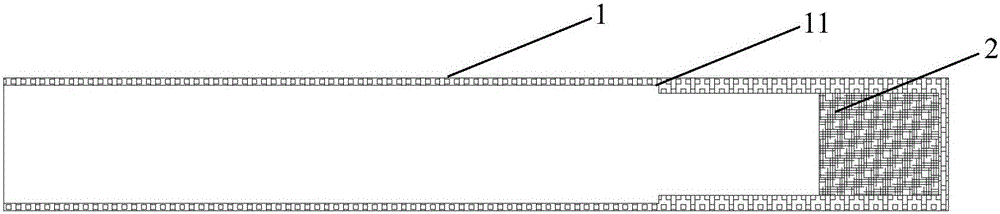

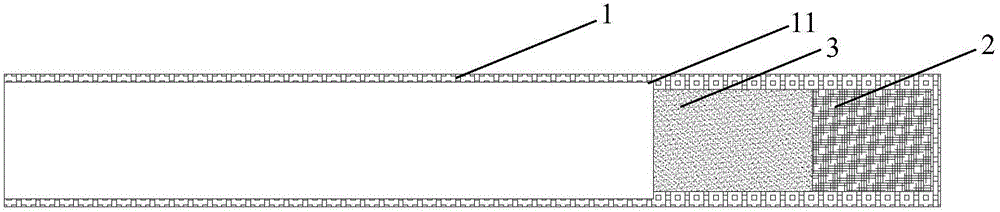

[0023] refer to Figure 1 to Figure 9 , trace detonator industrial nonel detonator includes: new detonator shell 1, primary charge 2, secondary charge 3, new reinforced cap 4, priming charge 5, delay body 6, card waist 7, rubber plug 8, detonation Tube 9, bayonet 10 constitutes. It is characterized in that: the novel detonator shell 1 is 66 mm long, the outer wall diameter is 7.02 mm, the inner diameter of the opening is 6.3 mm, the inner wall is provided with an inner platform 11 with an inner diameter of 6.2 mm, the inner platform 11 is 21 mm away from the bottom of the tube shell, and the tube wall is from the opening to the inner The wall thickness of platform 11 gradually increases, the inner diameter of the bottom of the tube shell is 6.1mm, and the wall thickness from inner platform 11 to the bottom of the tube gradually increases, forming a special internal structure with a larger inner diameter and a smaller inner diameter; the first charge 2 is: 0.42g of RDX -0.44g;...

Embodiment 2

[0026] The primary explosive 5 is 0.10g-0.13g of HNH, and the rest are the same as those in Embodiment 1, and will not be repeated here.

[0027] The present invention is characterized in that: the inner wall of the novel detonator shell 1 is provided with an inner platform 11 to form a special shell structure with a larger inner diameter and a smaller inner diameter; the novel reinforcing cap 4 is reversely pressed and mounted To the inner platform 11, a small amount of primer 5 is press-fitted in its "concave" structure, which produces an extremely stable static space in the cap, and the radial constraint is further strengthened. In this structure, after the primer is ignited and detonated, The power is further strengthened and amplified, and under the condition of greatly reducing the charge amount of the priming charge, the same effect of the present stage of the amount of the priming charge can be achieved.

[0028] The advantages and positive effects of the present inven...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Outer wall diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com