High-conductivity electrorheological fluid and preparing method thereof

An electrorheological fluid and high conductivity technology, applied in the petroleum industry, lubricating compositions, etc., can solve the problems of being unable to be widely used in industrial production, poor dispersion of solid particles, and poor compatibility of insulating fluids, etc., to achieve strong application and improve Conductivity, effects of a wide range of materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

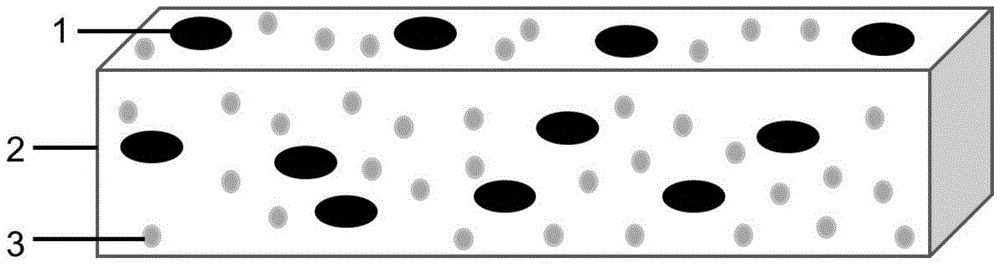

[0030] In order to avoid repetition, the raw materials used in this specific implementation are described in a unified manner as follows, and will not be repeated in the specific embodiments: figure 1 As shown, the high-conductivity electrorheological fluid of this embodiment is made by uniformly mixing liquid metal and in-situ synthesized electrorheological fluid as raw materials; the preparation method of the high-conductivity electrorheological fluid includes the following steps:

[0031] (1) Prepare in-situ synthesized electrorheological fluid by conventional in-situ synthesis method;

[0032] (2) Liquid metal is prepared by conventional methods;

[0033] (3) Mix the liquid metal and the electrorheological fluid synthesized in situ uniformly to obtain.

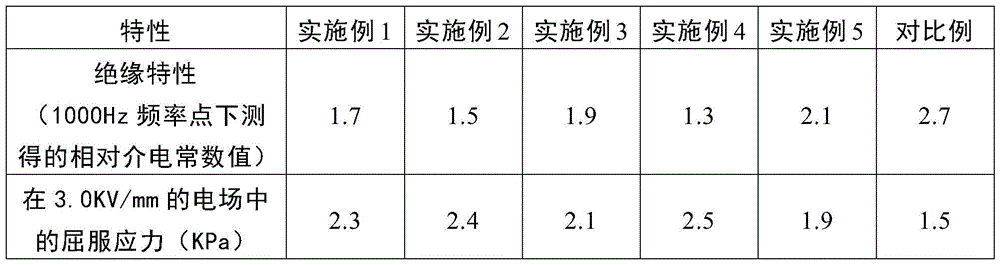

Embodiment 1

[0035] In the high-conductivity electrorheological fluid described in this embodiment, the content of liquid metal is 10% by mass, and the rest is the electrorheological fluid synthesized in situ.

[0036] Among them, the material of the liquid metal is gallium-indium binary alloy, the content of gallium is 90% by mass, and the rest is indium; the electrorheological fluid synthesized in situ is mixed with titanium dioxide powder particles in dimethyl silicone oil, and titanium dioxide powder The content of bulk particles is 20% by mass.

Embodiment 2

[0038] In the high-conductivity electrorheological fluid described in this embodiment, the liquid metal content is 15% by mass, and the rest is the electrorheological fluid synthesized in situ.

[0039] Among them, the material of the liquid metal is a gallium indium binary alloy, the content of gallium is 70% by mass, and the rest is indium; the in-situ electrorheological fluid is mixed with barium titanate particles in paraffin oxide wax, and the barium titanate particles The content is 20% by mass

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com