Target back plate and magnetron sputtering device for magnetron sputtering

A magnetron sputtering and backplane technology, applied in the field of magnetron sputtering, can solve the problems of reduced utilization rate of target material 1, uneven film thickness of the substrate to be coated, low utilization rate of target material, etc. Effectiveness of utilization, extended service life, improved uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] For ease of understanding, the target backing plate and the magnetron sputtering device provided by the embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

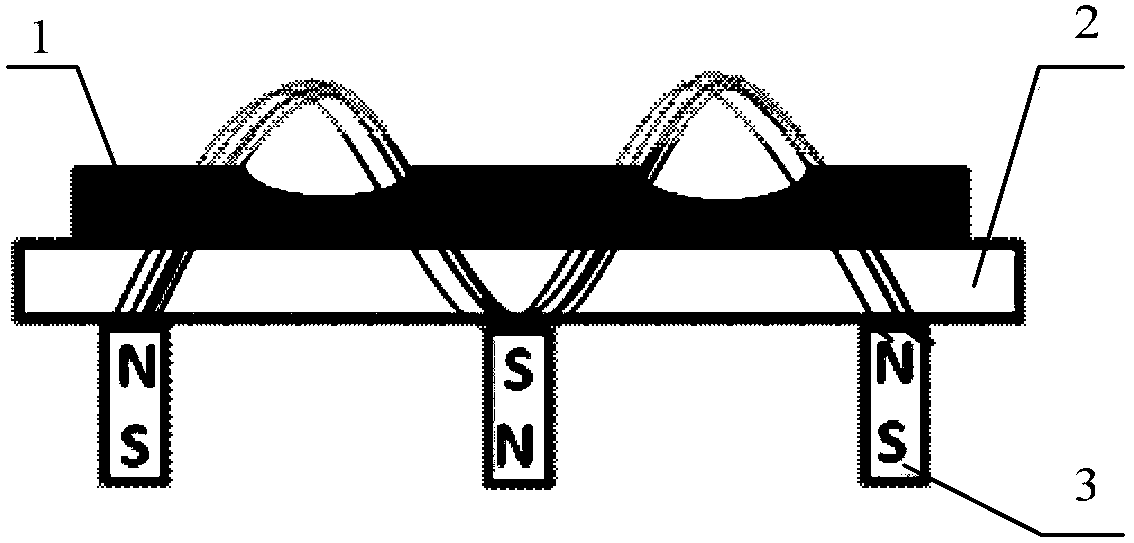

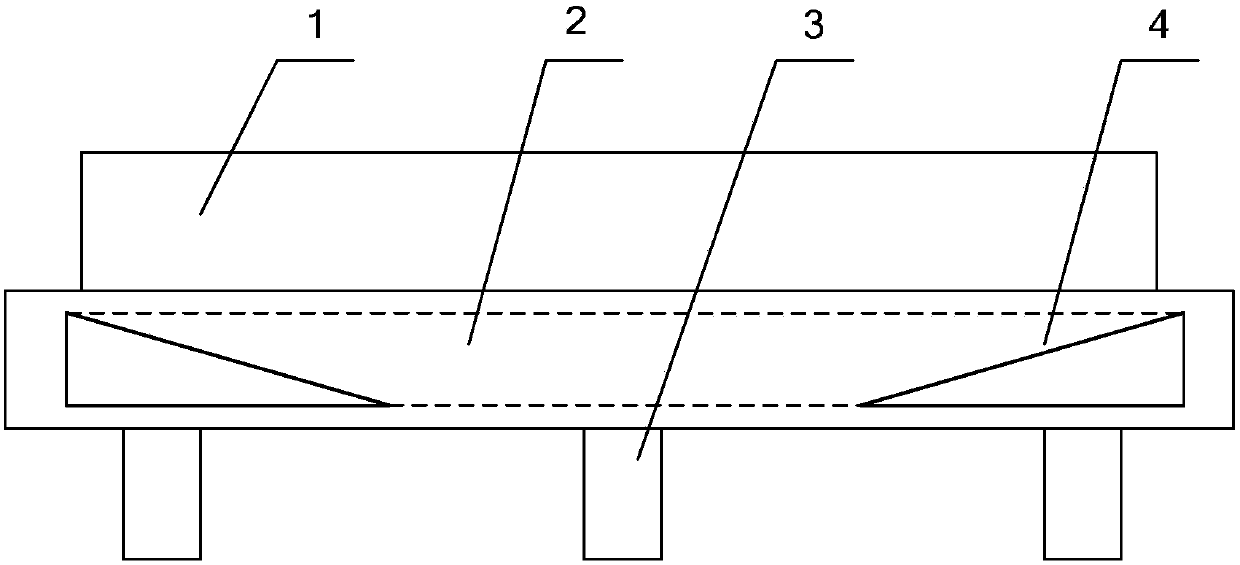

[0023] see figure 2 , in the embodiment provided by the present invention, the target back plate 2 is provided with a cooling liquid channel, the back of the target back plate 2 is provided with a plurality of magnets 3, and the cooling liquid channel of the target back plate 2 is also provided with a magnetic conductive sheet 4. The magnetically conductive sheet 4 corresponds to the strongest magnetic field strength area of the magnetic field generated by the plurality of magnets 3 .

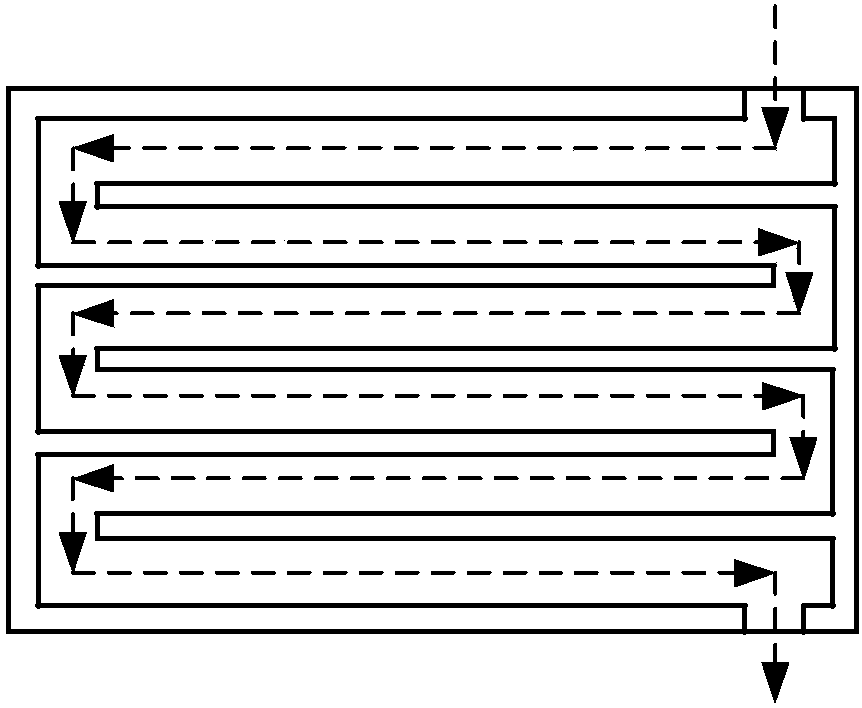

[0024] During specific implementation, the coolant channel provided in the target back plate 2 is as follows: image 3 As shown, the cooling liquid channel preferably adopts a serpentine channel, and there is a very thin separation plate at the adjacent channel of t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com