Reuse method of construction waste materials in coastal and island areas

A waste material and coastal technology, applied in the processing of building materials, construction, building structure, etc., can solve the problems of waste of resources, reduction of chloride ion concentration, and low degree of reuse, so as to ensure that it will not be corroded and prolong its use Lifespan, thorough dechlorination effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0024] The method for recycling building waste materials in coastal and island areas of the present invention has the following steps.

[0025] a. Crushing, removing impurities and grading the concrete waste formed by building demolition to form coarse aggregate, and then mixing the above coarse aggregate with fine aggregate such as sand and fly ash to form recycled concrete aggregate. The above-mentioned crushing, impurity removal, grading, mixing and other steps are all the same as the conventional prior art.

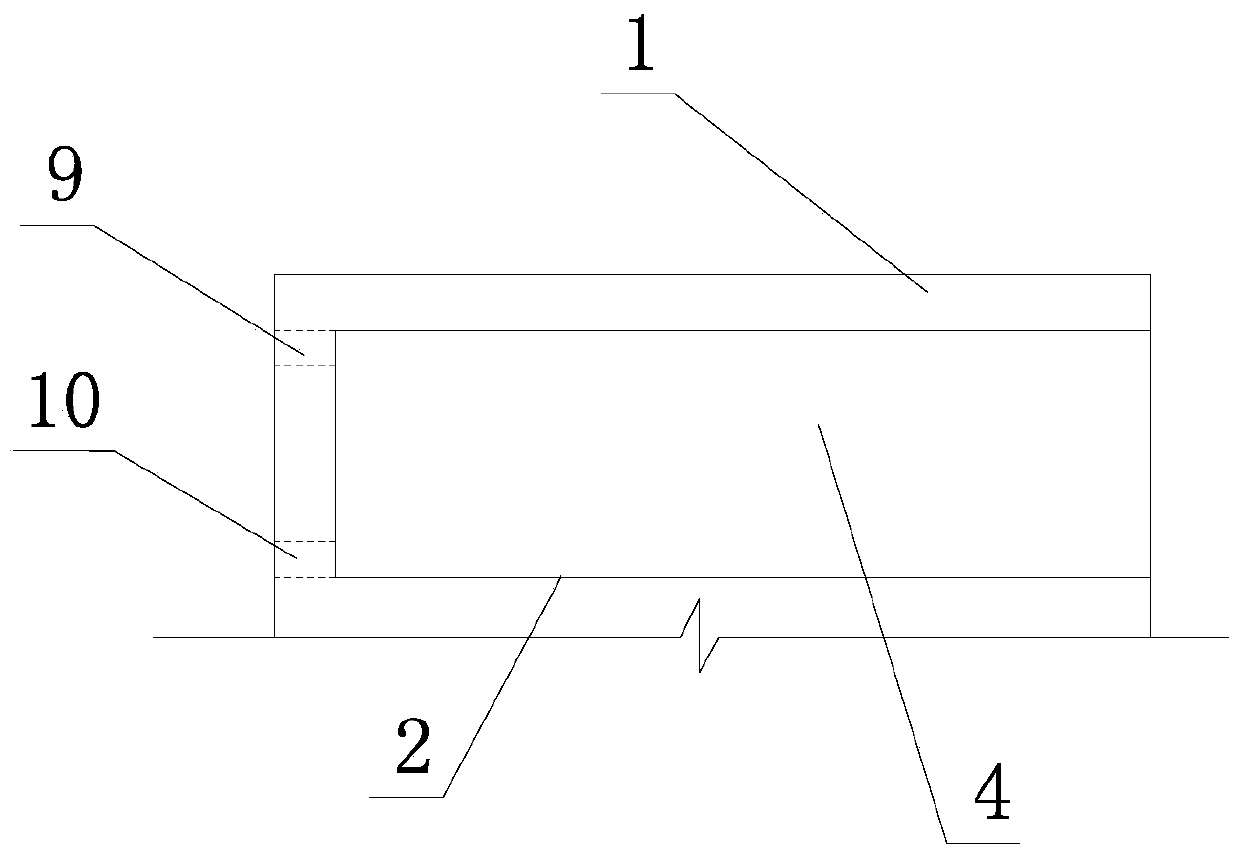

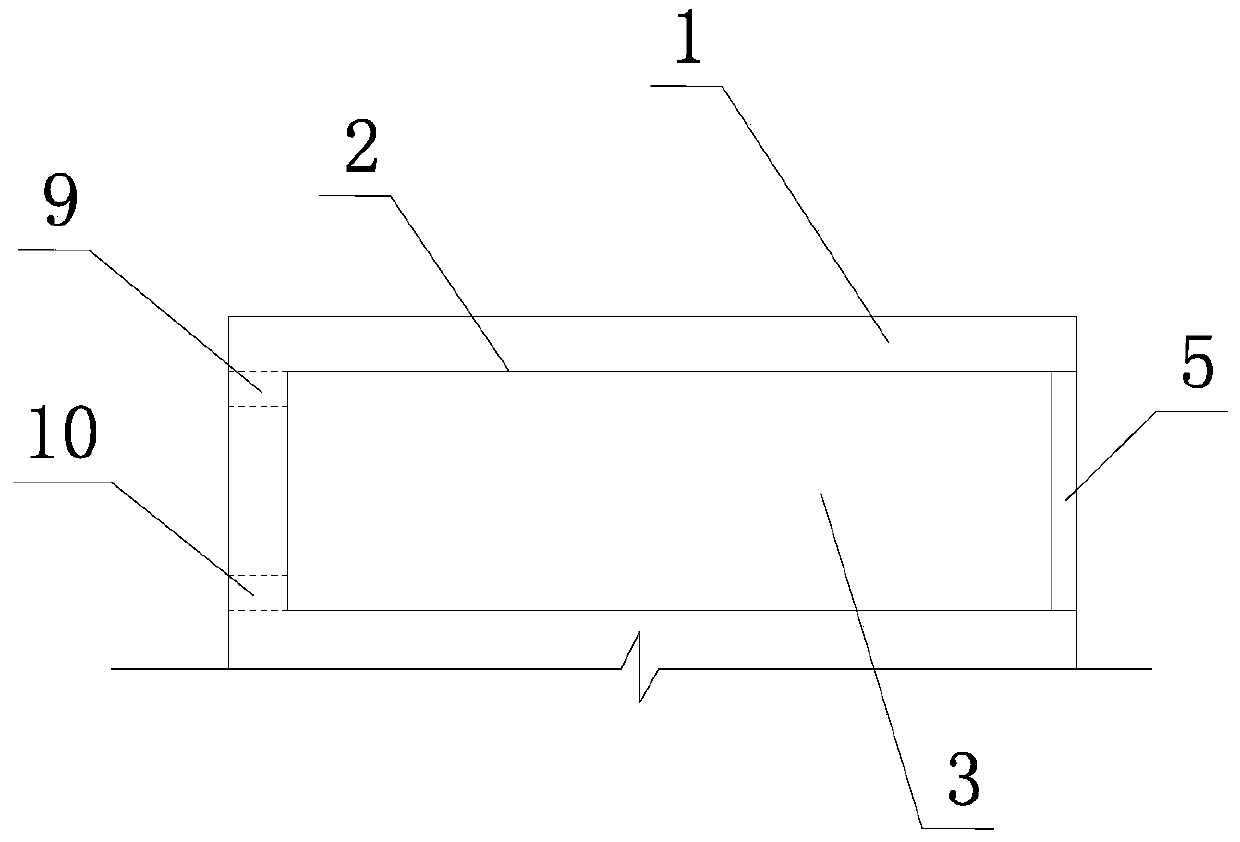

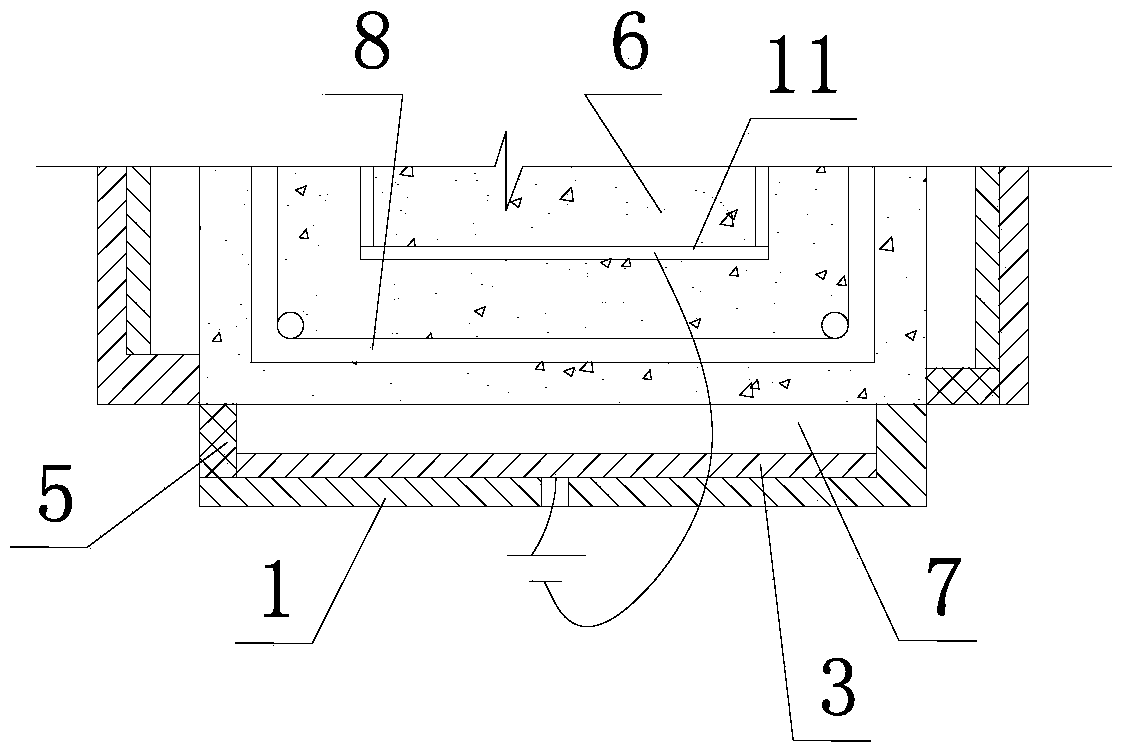

[0026] b. Manufacture formwork 1 for pouring concrete.

[0027] The inner surface of the formwork 1 is provided with a chute 2, and the bottom of the chute 2 is provided with a stainless steel plate 3, and the chute 2 is slidingly fitted with a pumping plate 4 equal in length to the chute 2, the pumping plate 4, the stainless steel pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com