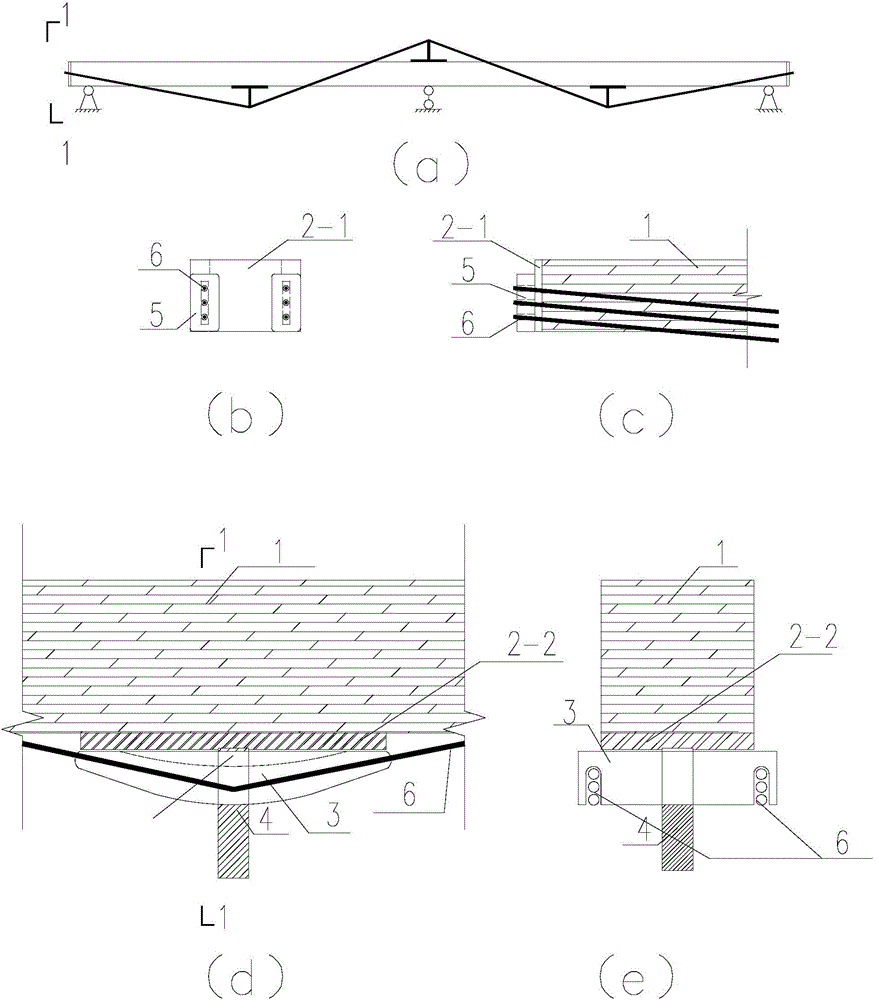

Novel bamboo and wood continuous beam prestressing force exertion system

A technology of prestressing and wooden beams, which is applied in construction, building structure, and processing of building materials, etc. It can solve the problems affecting the normal use of beams, the increase of cross-sectional size and self-weight, and the increase of bending moment value, so as to achieve convenient regulation and construction. Convenience, the effect of reducing concentrated stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0019] Embodiment: test group: prestressed continuous beam size 6000X100X100, comparison group: prestressed simply supported beam size 6000X100X100. Loading under the same environment (two-point loading F=10kN, loading step by step; the elastic modulus of wood is 10000N mm), the internal force and deformation results are as follows:

[0020] Simply supported beam: Since the deflection has reached the maximum limit, the load cannot be continued, and the maximum bending moment value added is 0.5kN·m. Continuous beam: the maximum bending moment value is 4.68kN·m, and the maximum deflection at mid-span is 29mm.

[0021] It can be concluded that when the deflection is the main control factor, the continuous beam has great advantages compared with the simply supported beam.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com