Gas extraction method based on high-pressure hydraulic cave construction on bedding hole of driving working face

A technology for excavation working face and gas drainage, which is applied in the direction of drilling equipment and methods, gas discharge, mining equipment, etc., and can solve problems such as unsuitable for high-speed mining of coal seams, high economic costs, and no substantial improvement in coal seam mining efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be described in detail below with reference to the accompanying drawings and specific embodiments. This embodiment is based on the technical solution of the present invention as a prerequisite, and provides detailed implementation and specific operating procedures.

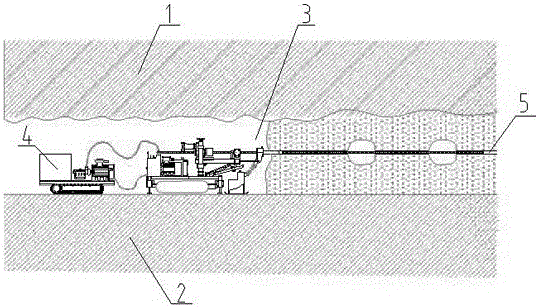

[0025] The present invention is a method for gas drainage with high pressure hydraulic caverns along bedding holes in a driving face. Drilling holes are constructed in the driving face 3 of a soft and high outburst coal seam, and caves are constructed in the coal seam by means of hydraulic jet punching. A fissure expansion zone is formed around the cave to improve the permeability of the coal seam and increase the efficiency of gas drainage. The boreholes constructed are horizontal boreholes5.

[0026] The coal seam for hydraulic cavitation pressure relief and permeability enhancement is a soft and high outburst coal seam, and the coal seam is a medium thick coal seam.

[0027] The hydra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com