A clearance-adjustable twin-screw pump

A twin-screw pump, adjustable technology, applied in the direction of pumps, pump components, rotary piston pumps, etc., can solve the problems of increased material leakage, high maintenance costs, and reduced pump performance, so as to reduce maintenance costs and save maintenance time The effect of cost and material reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, but the protection scope of the present invention is not limited thereto.

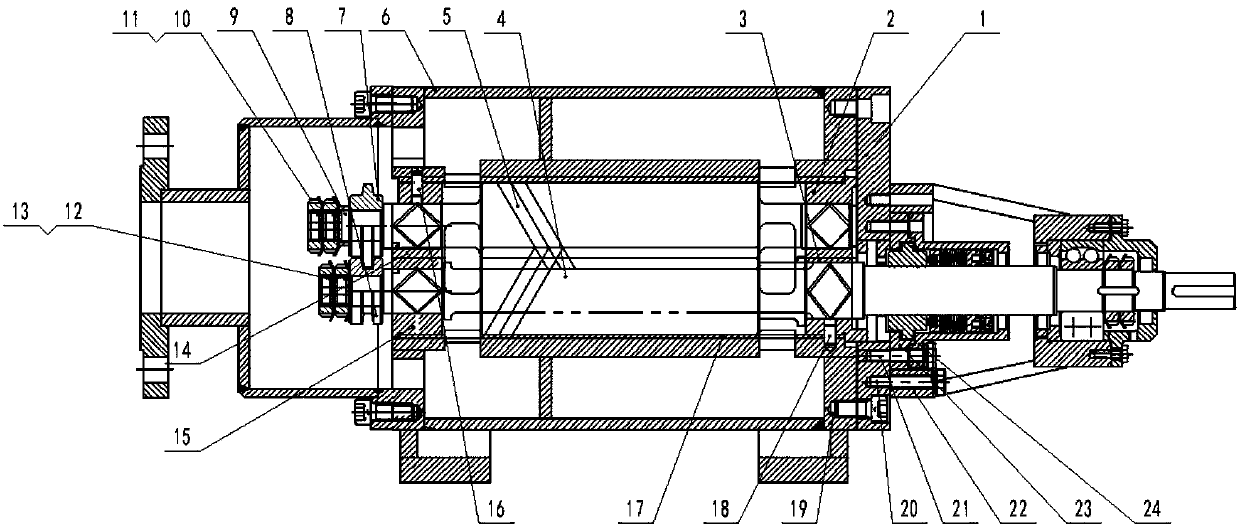

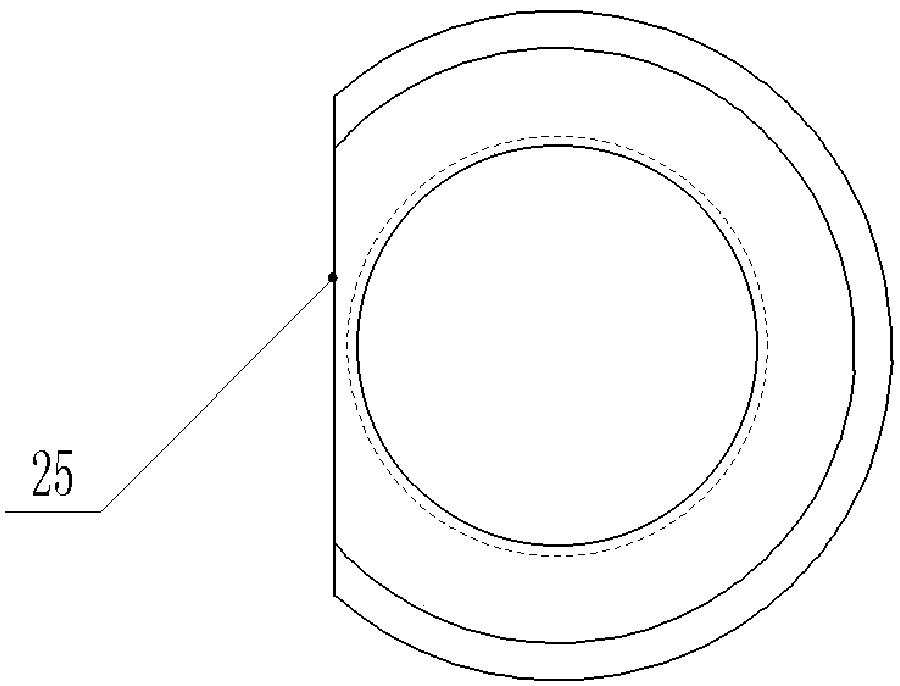

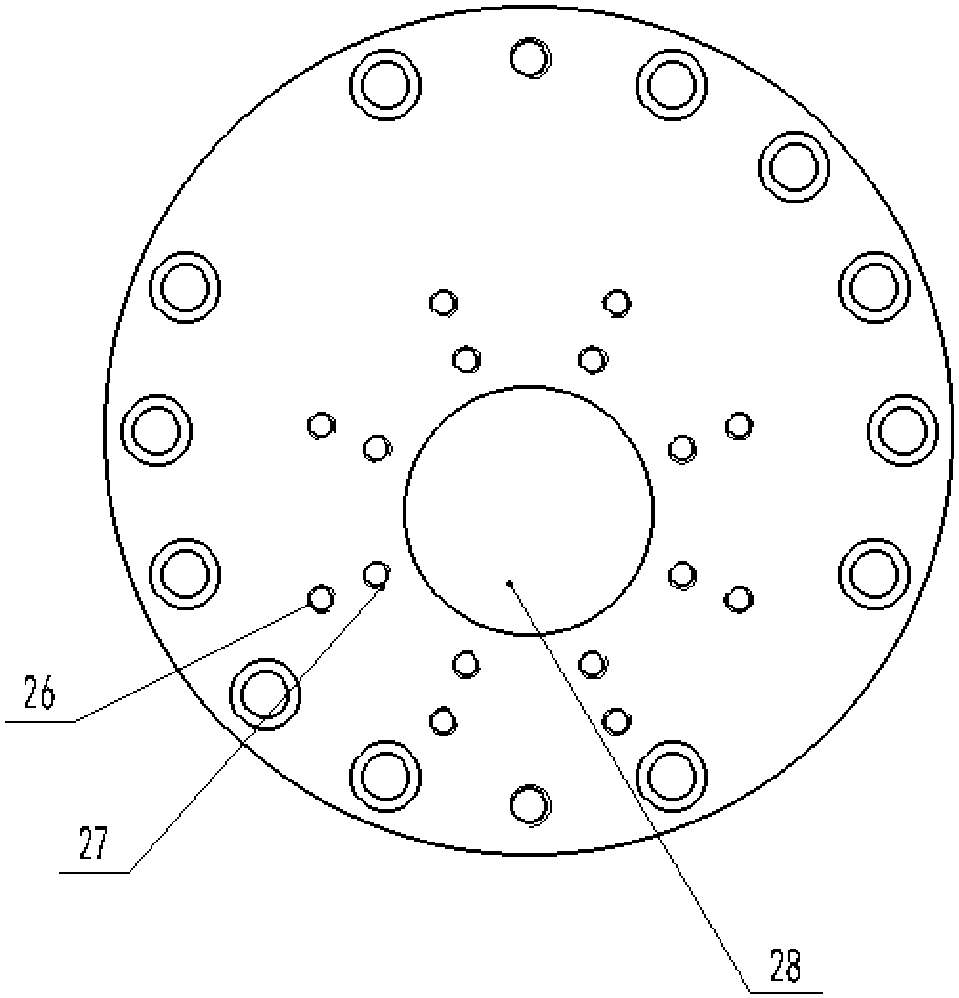

[0028] figure 1Schematic diagram of the twin screw pump assembly. In addition to the proper structure of a conventional single-suction twin-screw pump, this twin-screw pump also includes a replaceable inner bush 17, a replaceable pump front cover 1, a machinable main screw front sliding bearing seat 3, a main The sliding bearing seat 15 behind the screw rod, the sliding bearing seat 2 and the corresponding rear sliding bearing seat 14 from the front screw rod. In terms of the inner bushing 17: the inner bushing 17, the pump body 6 and the front sliding bearing seat 3 of the main screw are connected by pins 18; in addition, the inner bushing 17, the pump body 6 and the rear sliding bearing seat 14 of the slave screw The pin 16 connection holds the inner bushing 17 axiall...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com