Waste heat utilization cyclone separator

A cyclone separator and waste heat technology, applied in the direction of heat exchanger, indirect heat exchanger, cyclone device, etc., can solve the problem of increased resistance loss of flue gas in the dust collector, affecting the heat exchange effect of equipment, and increasing heat exchange Surface thermal resistance and other issues can be avoided to avoid waste heat loss, improve integration and reduce thermal resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

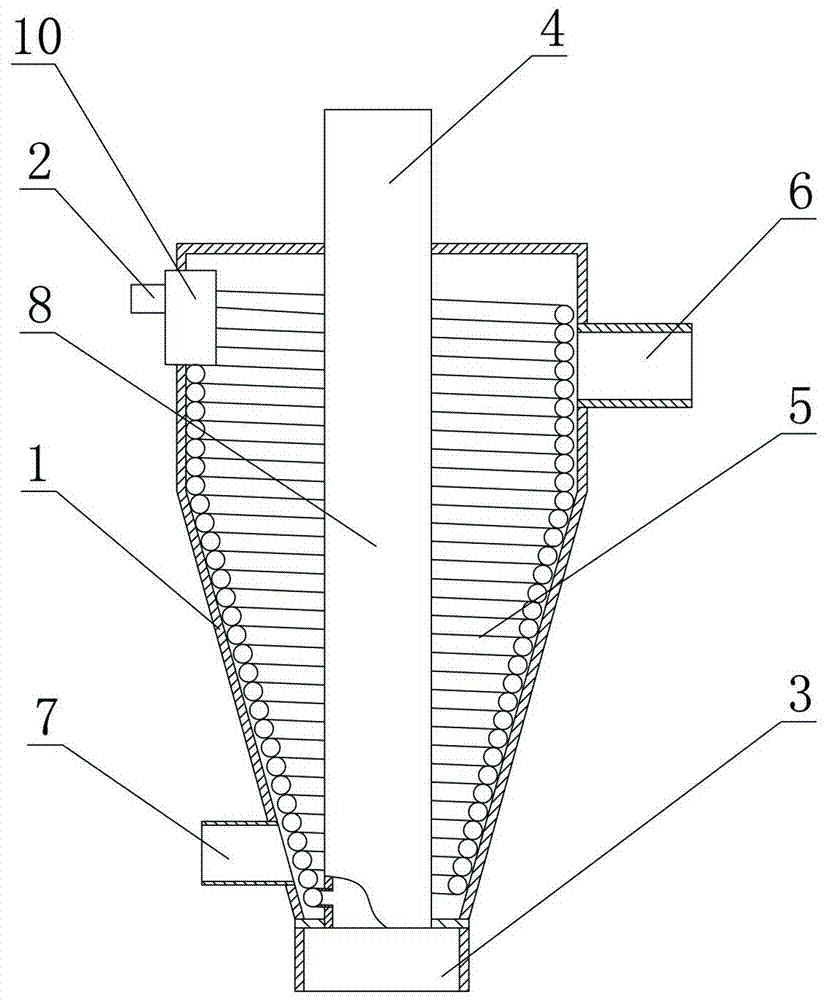

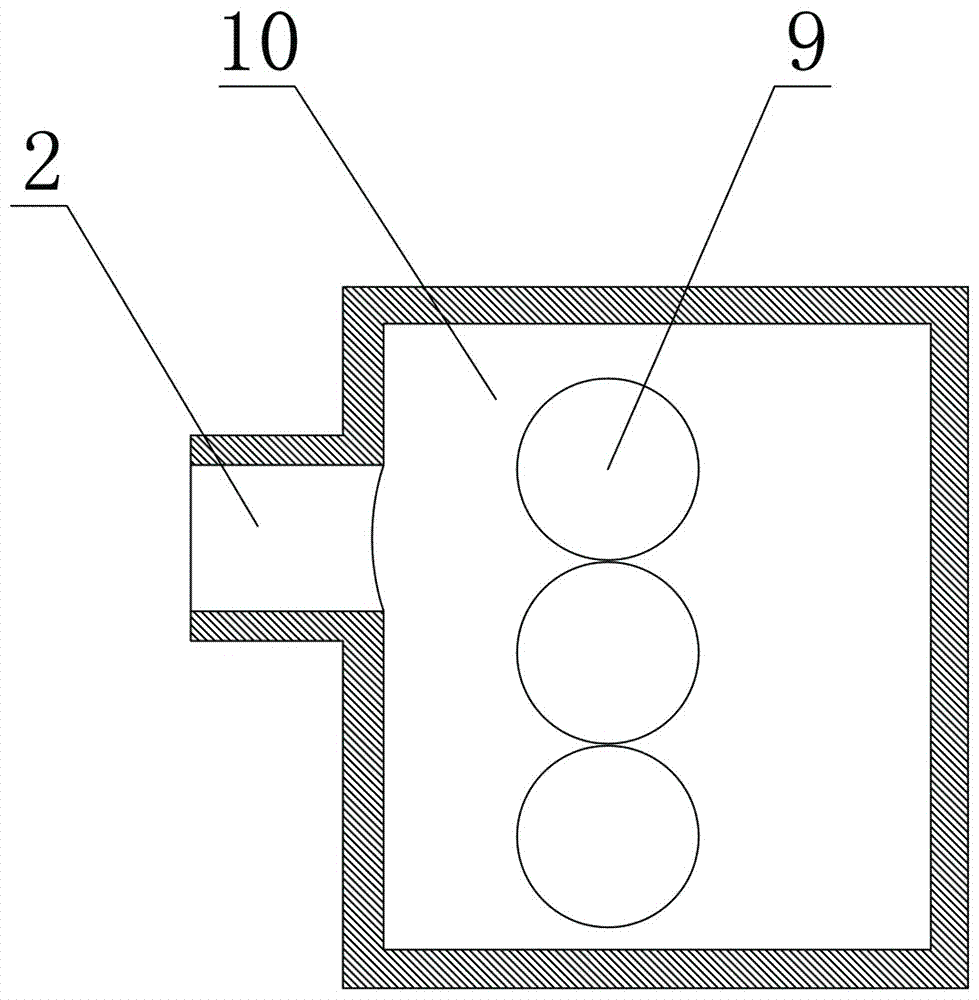

[0025] Such as figure 1 and figure 2 As shown, a waste heat utilization cyclone separator includes a housing 1, a dusty gas inlet 2 arranged on the side of the housing 1, an air inlet distributor 10, an ash discharge port 3 arranged at the lower end of the housing 1 and a device At the clean gas outlet 4 on the top of the housing 1, a group of spiral pipes 5 are arranged in the housing 1, and the upper ends of a group of the spiral pipes 5 are sealed and connected to the dust-containing gas inlet 2, and a group of the spiral pipes 5 The lower end of the ash discharge port 3 is sealed and communicated with the ash discharge port 3, and the ash discharge port 3 is sealed and connected with the clean gas outlet 4 through the air riser 8, and the ash discharge port 3 is isolated from the shell side space of the housing 1. A heat exchange medium inlet 6 and a heat exchange medium outlet 7 communicating with the shell side space are provided on the upper side and the lower side of...

Embodiment 2

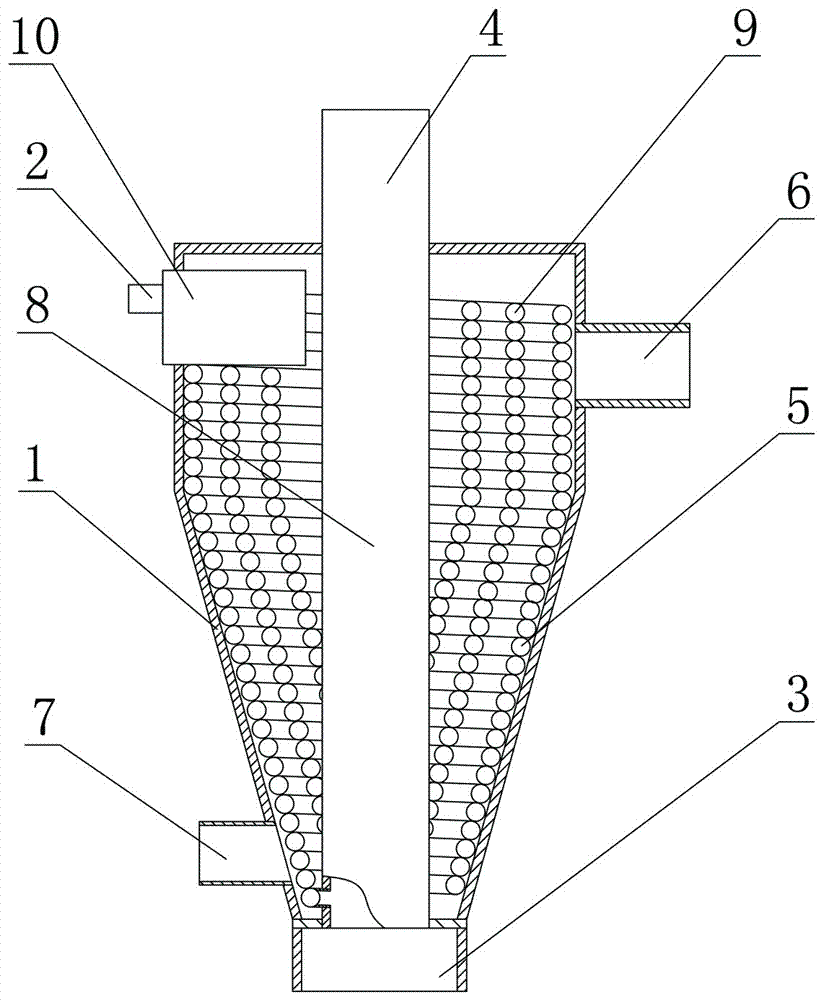

[0031] Such as image 3 As shown, the difference between this embodiment and Embodiment 1 is that it also includes at least one set of inner helical ducts 9, the upper end of each set of inner helical ducts 9 communicates with the dust-laden gas inlet 2, each set of inner helical ducts The lower end of the pipeline 9 communicates with the ash discharge port 3 , there is a gap between each group of internal spiral pipelines 9 , and there is a gap between the outermost group of internal spiral pipelines 9 and the spiral pipeline 5 . The lower end of the spiral duct 5 and the lower ends of the inner spiral ducts 9 are both pierced on the side wall below the air riser 8 , and then communicated with the ash discharge port 3 .

[0032] Add a sufficient number of spiral pipes to find a balance between ensuring the flow rate of high-temperature dust-laden gas and heat exchange efficiency, so as to achieve the best heat exchange capacity and solid-gas separation capacity.

[0033] In ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com