Metal layer pulsed eddy current thickness measurement method

A pulsed eddy current and metal layer technology, applied in measuring devices, electromagnetic measuring devices, electromagnetic/magnetic thickness measurements, etc., can solve the problem of indistinguishable useful signals, and achieve the effect of improving anti-interference ability and accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

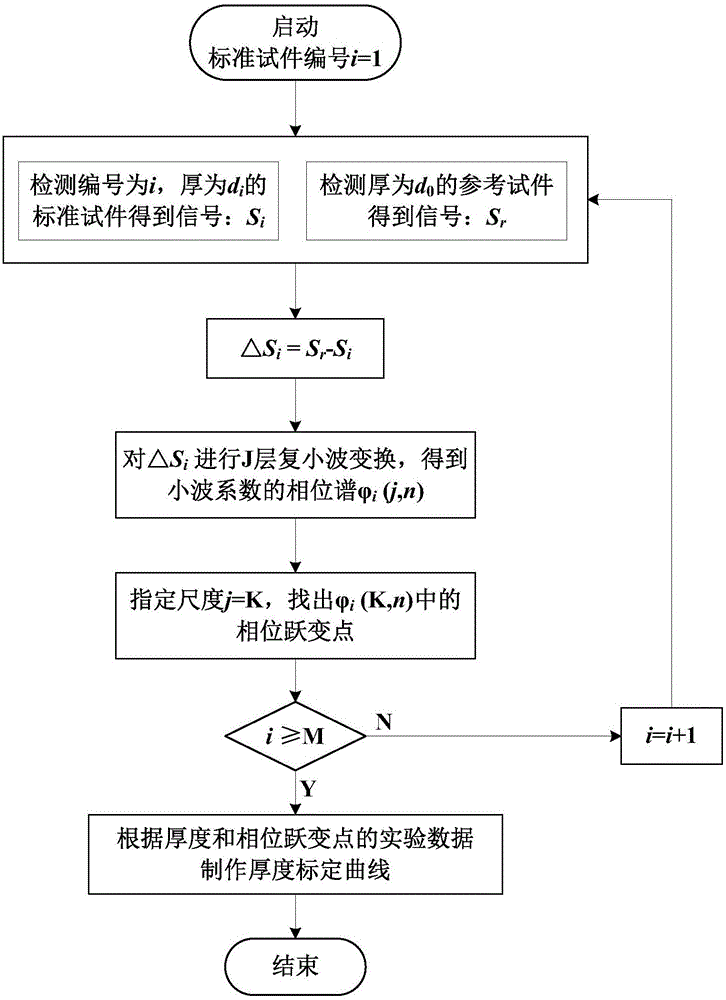

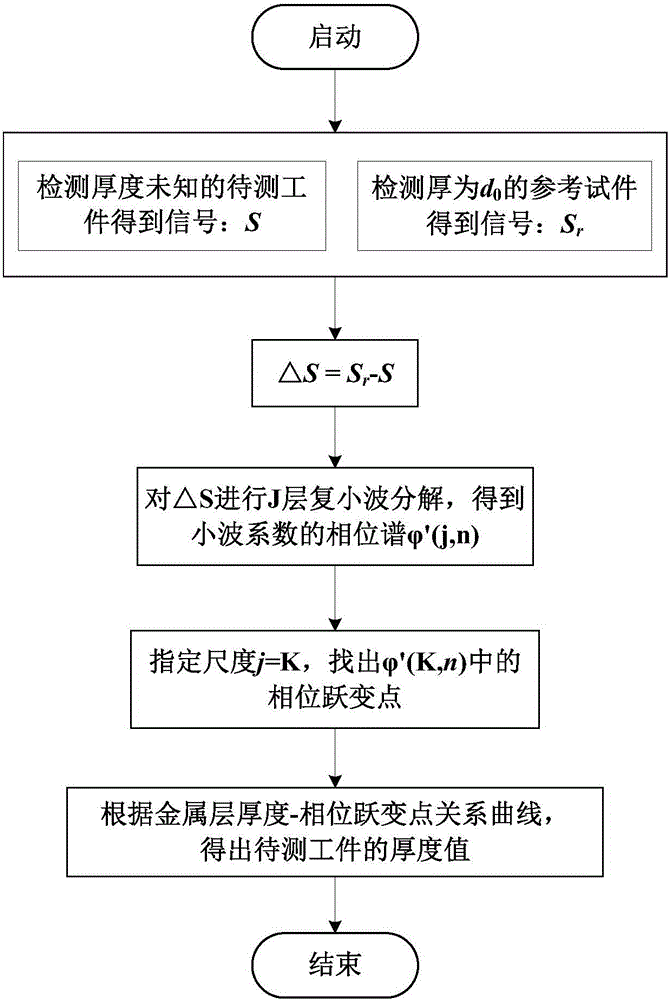

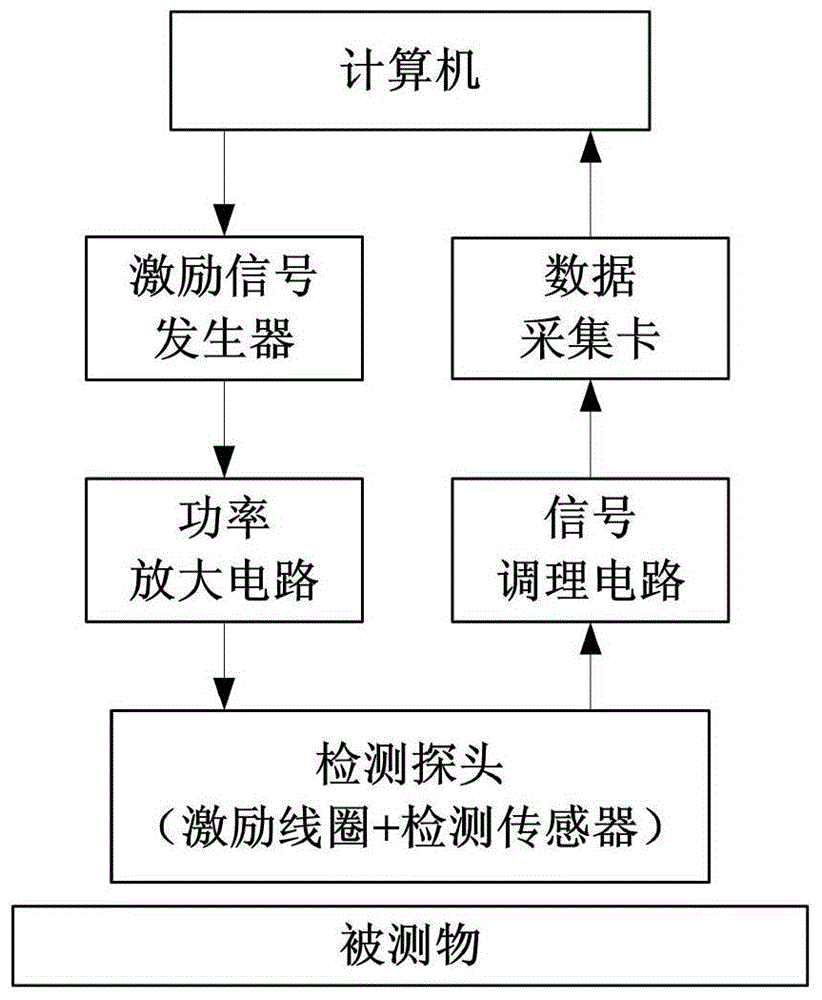

[0030] Combine below Figure 1 to Figure 6 Further describe the technical solution of the present invention in detail, but the protection scope of the present invention is not limited to the following description.

[0031] Such as figure 1 As shown, a pulsed eddy current detector includes an excitation signal generator, a power amplifier circuit, a detection probe (including an excitation coil and a detection sensor), a signal conditioning circuit, a data acquisition card and a computer. Among them, the excitation signal generator generates an electrical signal with a pulse waveform, which is amplified by the power amplifier circuit, and then loaded into the excitation coil. When the detection probe is close to the measured object of conductive material, an electromagnetic field is generated between the detected object and the measured object. In order to realize the coupling effect, the detection sensor is used to convert the induced magnetic field into an electrical signal,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com