Linear steering engine loading device

A technology of loading device and steering gear, which is applied in the testing of measuring devices, machine/structural components, and the measurement of forces applied to control elements, etc. manufacturability, improved work efficiency, and low-cost effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

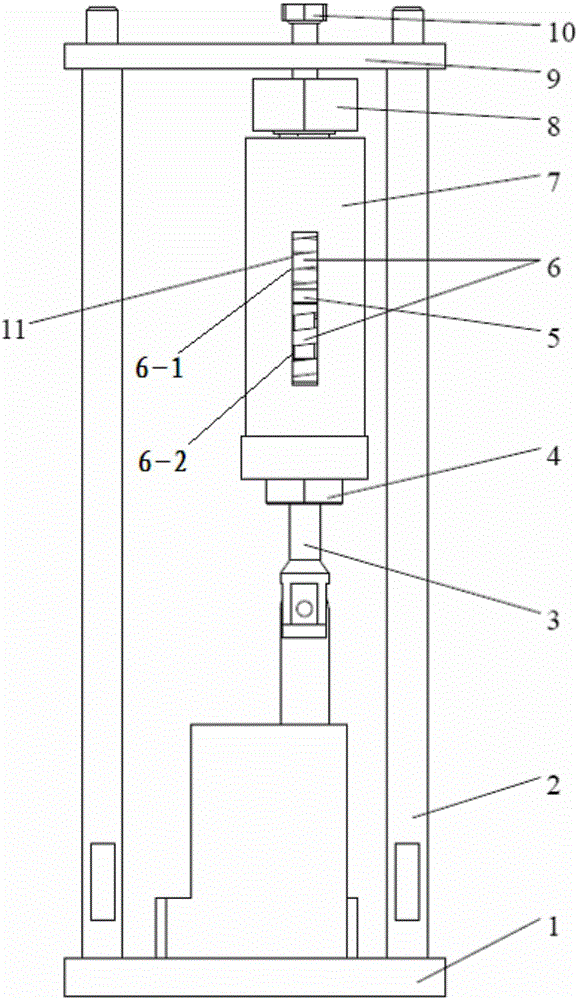

[0033] like figure 1 Shown is the structural diagram of the linear steering gear loading device. It can be seen from the figure that it includes the lower base plate 1, the column 2, the connecting rod 3, the end cover 4, the piston 5, the spring 6, the casing 7, the nut 8, the upper base plate 9, and the bolt 10 and the display window 11; the thread and the nut passed by the upper base plate 9 are installed on the column 2; the upper base plate 9 is installed on the lower base plate 1 through the column 2; One end is fixedly connected; the other end of the connecting rod 3 extends into the shell 7 through the end cover 4, and the connecting rod 3 and the piston 5 are connected by pins; the end cover 4 is tightened on the lower part of the shell 7; the shell 7 is installed on the upper bottom plate 9 through bolts 10 The lower part is locked wi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Outer diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com