Method for predicting cutting defects of carbon fiber reinforced composites

A technology for enhancing composite materials and cutting processing, which is applied in the direction of analyzing materials, using sonic emission technology for material analysis, and using sonic/ultrasonic/infrasonic waves for material analysis. It can solve problems such as high cost and achieve high reliability and simple operation. handy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

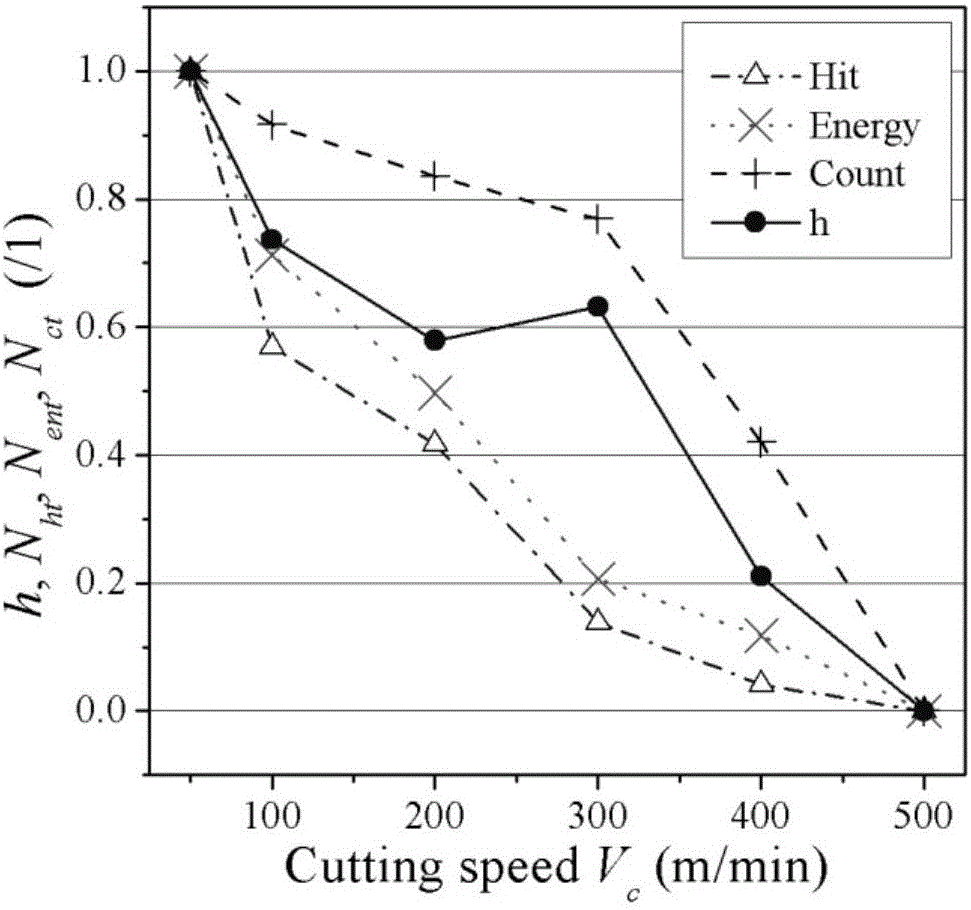

[0034] The collected signals of T800 / X850 carbon fiber reinforced composites are shown in Table 1.

[0035] Substitute the data in Table 1 into Equation (1), and solve the overdetermined linear equation to obtain the linear relationship equation between the tearing depth h and the three AE meter quantitative parameters during cutting of T800 / X850 carbon fiber reinforced composites. Linear coefficients a, b, c. From this, the prediction model of the tear defect on the inlet and outlet sides of the T800 / X850CFRP unidirectional laminate based on the AE signal can be obtained:

[0036] h = 136.3584 N h t L - 4.064 N e n t L + 4.2544 N c ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com