Host bone stress environment based custom prosthesis optimization design method

An optimized design and prosthesis technology, applied in design optimization/simulation, calculation, special data processing applications, etc., can solve the problems of limited stress distribution change, limited stress shielding relief, and complex stress conditions, etc., to achieve optimal prosthesis Internal porous structure, life-span improvement, inward growth promotion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention will be further described in detail below with reference to the accompanying drawings and embodiments. It should be understood that the embodiments described here are only used to illustrate and explain the present invention, but the embodiments of the present invention are not limited thereto.

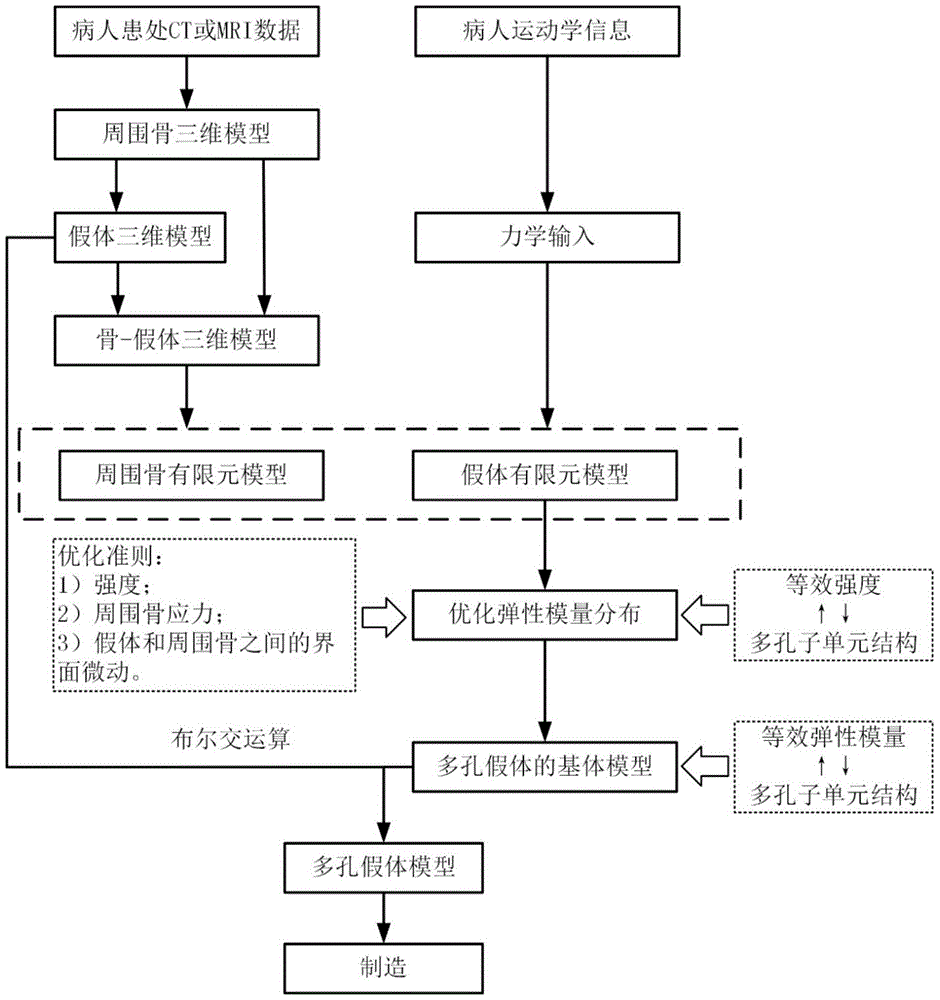

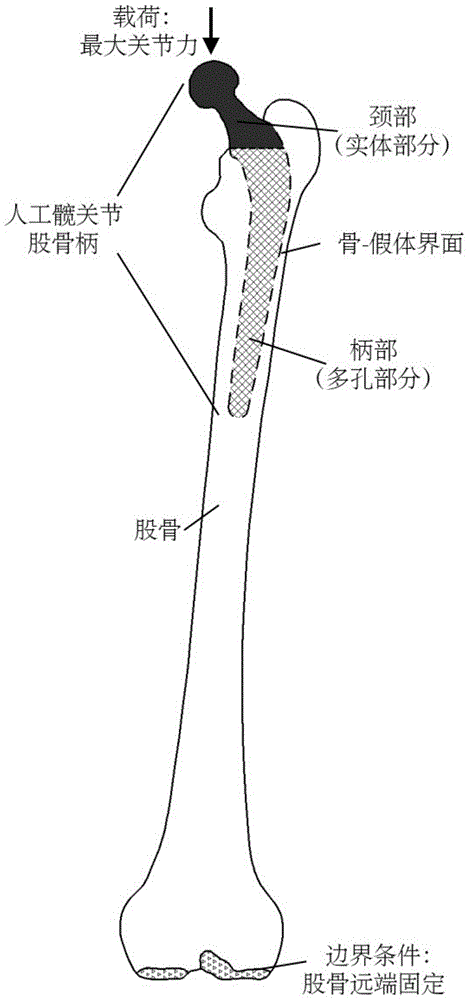

[0041] refer to figure 1 , taking the femoral stem prosthesis of the artificial hip joint as an example, the implementation method is as follows:

[0042] Step 1: Collect the CT data of the patient's hip joint, and establish a three-dimensional model of the patient's surrounding bone, that is, the three-dimensional model of the femur, through Mimics (Version16.0, Materialize, Belgium) software, and then perform osteotomy according to the surgical requirements and according to the shape of the three-dimensional femoral model The three-dimensional model of the femoral stem of the artificial hip joint was obtained by designing the shape of the prosthesis, and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Initial elastic modulus | aaaaa | aaaaa |

| Pore diameter | aaaaa | aaaaa |

| Porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com