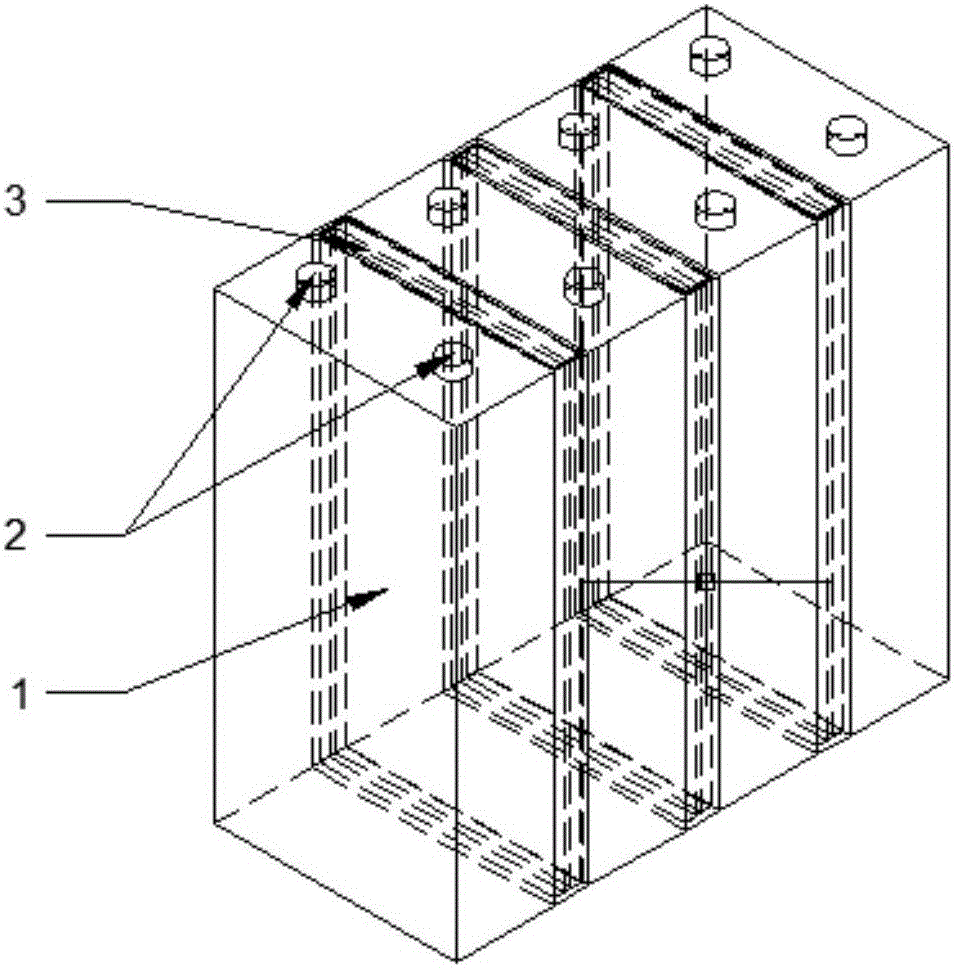

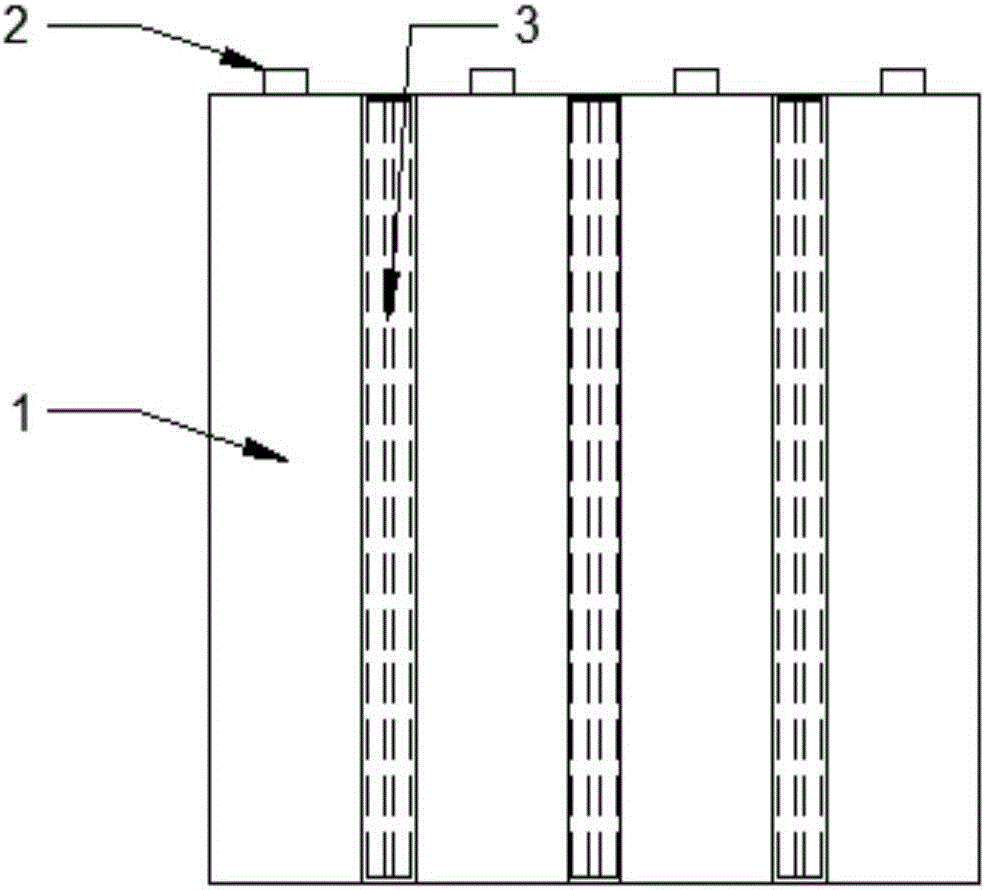

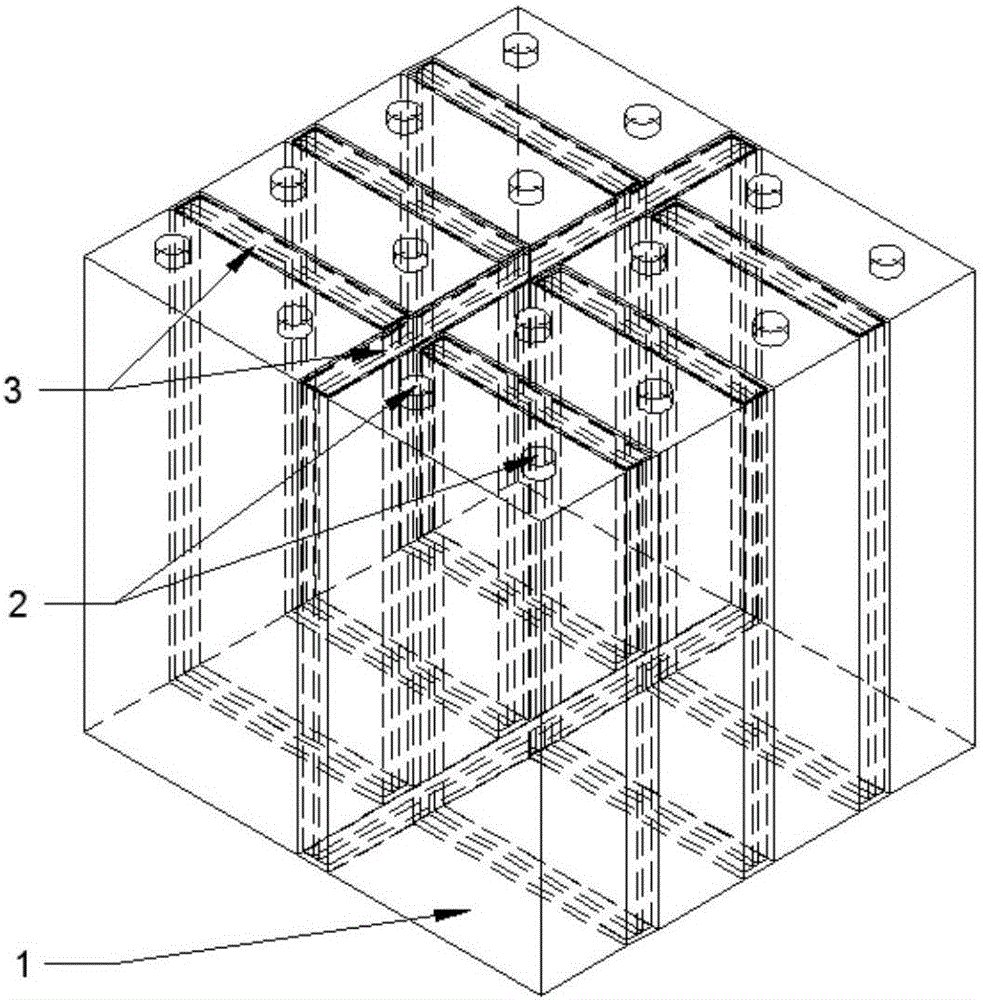

Composite plate for heat dissipation and thermal runaway propagation prevention of battery system

A battery system and composite board technology, applied in the direction of secondary batteries, circuits, electrical components, etc., can solve the problems of reducing the performance of thermal runaway propagation, difficulty in synergy, and uneven temperature distribution of batteries, achieving good market prospects, Improved uniformity and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] On the one hand, in order to study the heat dissipation capability of the composite board 3, 4 different structures were designed for comparative analysis, namely: the close contact between the battery cells 1, the air gap of 1 cm between the battery cells 1, and the battery cells. Install a 1 cm thermal conductive plate between 1 and a 1 cm composite plate 3 between the battery cells 1 . Place 3 battery cells 1 in the battery box, let each battery cell 1 discharge at the same rate, and then change the discharge rate (1C, 3C, 5C, 10C), and compare the maximum temperature and maximum temperature difference.

[0044] from Figure 8 It can be seen that there is little difference in the maximum temperature between the air space between the battery cells and the tight fit, indicating that simply increasing the space between the cells cannot effectively improve the heat dissipation capacity of the battery pack. The installation of thermal conductive plates between the batte...

Embodiment 2

[0046] On the other hand, in order to study the thermal runaway barrier capability of the composite board 3, and to simulate the thermal runaway situation of the battery, the first battery cell 1 is used as a thermal runaway battery, and the heat release rate is equivalent to the discharge heat generation at 10C, and the duration For 2000s, the remaining two battery cells 1 do not work. Here, the criterion for the start of thermal runaway of the battery is that the temperature of the battery cell 1 reaches 373.15K. Based on this, the time interval Δt of the thermal runaway of two adjacent batteries is calculated to analyze the respective thermal runaway barrier capabilities.

[0047] It can be seen from Table 1 that although the time interval Δt for the thermal runaway of the two batteries is the longest under the condition that the battery cells are separated by air, the temperature of the first thermal runaway battery can reach 354°C after 2000s, which is much higher than Co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thermal conductivity | aaaaa | aaaaa |

| Thermal conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com