Device for treating oil dirt in sewage with rotational flow method and removal method of oil dirt in sewage with rotational flow method

A technology for oil pollution and sewage, which is applied to the cyclone method to treat oil pollution in sewage and its removal field, can solve the problems of land occupation, system maintenance, and high use costs, and achieve the improvement of the oil pollution purification rate, the oil pollution purification rate is remarkable, and the scope of application expansive effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

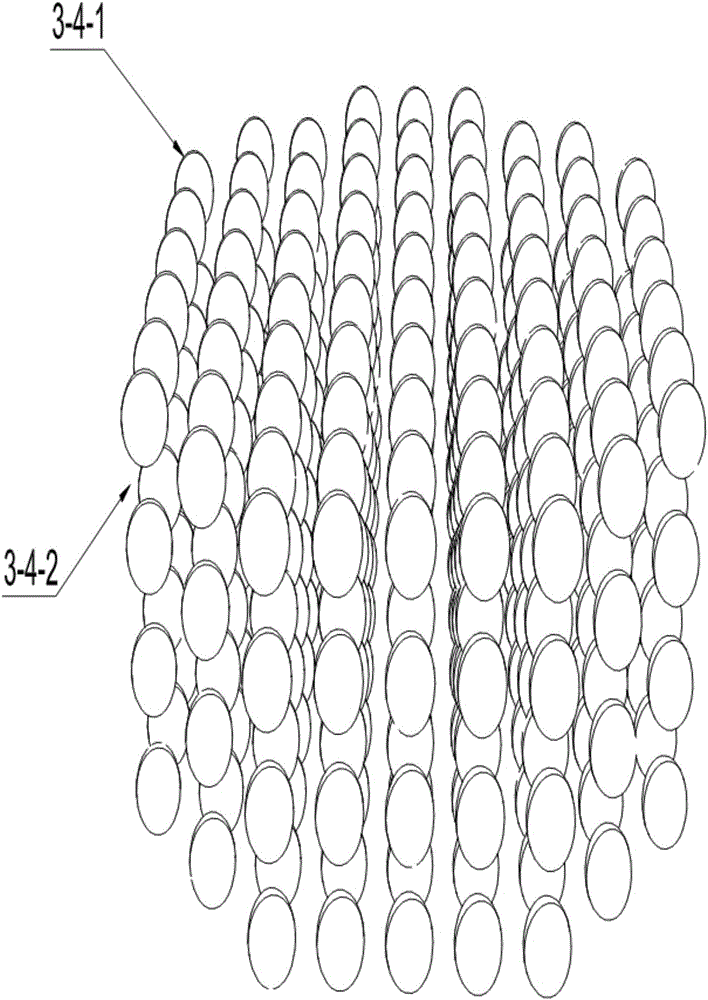

[0051] In parts by weight, the oil-absorbing particles 3-4-1 of the present invention are produced according to the following steps:

[0052] Step 1: Add 250 parts of ultrapure water with a conductivity of 0.02μS / cm into the reactor, start the stirrer in the reactor at a speed of 90rpm, start the heating pump, and raise the temperature in the reactor to 52°C; add in sequence 12 parts of rare earth phosphate, 16 parts of acetaldehyde n-propylthiol acetal, 8 parts of 2-methoxyacetaldehyde dimethyl acetal, stir until completely dissolved, adjust the pH value to 3.7, adjust the speed of the agitator to 113rpm, and the temperature 63°C, esterification reaction for 3.5 hours;

[0053] Step 2: Take 1 part of 2-ethylhexanal cycloethylene glycol acetal, 9 parts of dimethyl chloride acetal, and the particle size of the powder is 310 mesh; add 18 parts of formaldehyde diethylene glycol monobutyl ether and mix Spread evenly in the tray with a tile thickness of 11mm, irradiate with α-rays...

Embodiment 2

[0058] In parts by weight, the oil-absorbing particles 3-4-1 of the present invention are produced according to the following steps:

[0059] Step 1: Add 750 parts of ultrapure water with a conductivity of 0.09μS / cm into the reactor, start the stirrer in the reactor at a speed of 160rpm, start the heating pump, and raise the temperature in the reactor to 73°C; add in sequence 55 parts of rare earth phosphate, 27 parts of acetaldehyde n-propylthiol acetal, 35 parts of 2-methoxyacetaldehyde dimethyl acetal, stir until completely dissolved, adjust the pH value to 8.8, adjust the speed of the agitator to 178rpm, and the temperature 98°C, esterification reaction for 17 hours;

[0060] Step 2: Take 13 parts of 2-ethylhexanal cycloethylene acetal, 22 parts of dimethyl chloride acetal, and the powder particle size is 800 mesh; add 45 parts of formaldehyde diethylene glycol monobutyl ether and mix Spread evenly in the tray with a tile thickness of 29mm, irradiate with α-rays with a dose...

Embodiment 3

[0065] In parts by weight, the oil-absorbing particles 3-4-1 of the present invention are produced according to the following steps:

[0066] Step 1: Add 259 parts of ultrapure water with a conductivity of 0.029μS / cm into the reaction kettle, start the agitator in the reaction kettle at a speed of 99rpm, start the heating pump, and raise the temperature in the reaction kettle to 59°C; add in order 17 parts of rare earth phosphate, 18 parts of acetaldehyde n-propylthiol acetal, 18 parts of 2-methoxyacetaldehyde dimethyl acetal, stir until completely dissolved, adjust the pH value to 4.8, adjust the speed of the agitator to 118rpm, and the temperature At 68°C, the esterification reaction took 3.9 hours;

[0067] Step 2: Take 11 parts of 2-ethylhexanal cycloethylene acetal, 13 parts of dimethyl chloride acetal, and the powder particle size is 314 mesh; add 21 parts of formaldehyde diethylene glycol monobutyl ether and mix Spread evenly in the tray with a tile thickness of 19mm, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com