Vertical type intelligent combination gear box

A kind of gear box, intelligent technology, applied in the direction of belt/chain/gear, transmission box, components with teeth, etc., can solve the problem of immature technology, reduce production cost, improve production efficiency and rolling stock dimensional accuracy. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

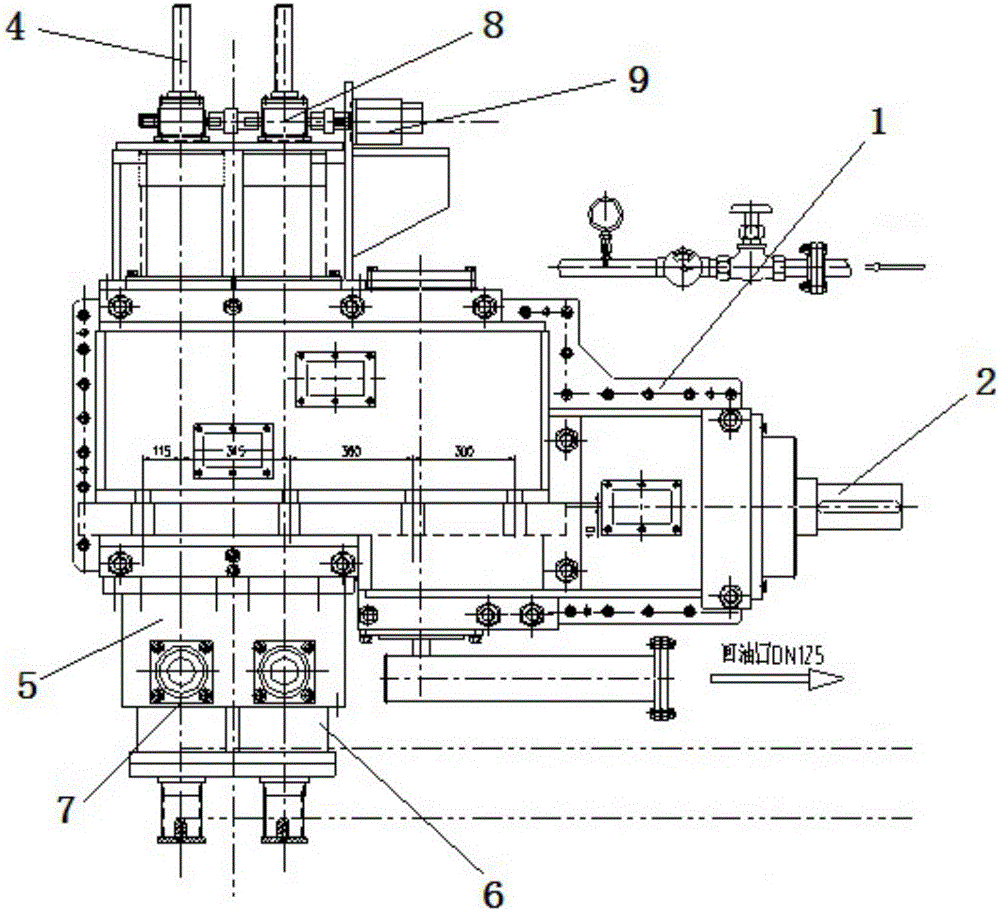

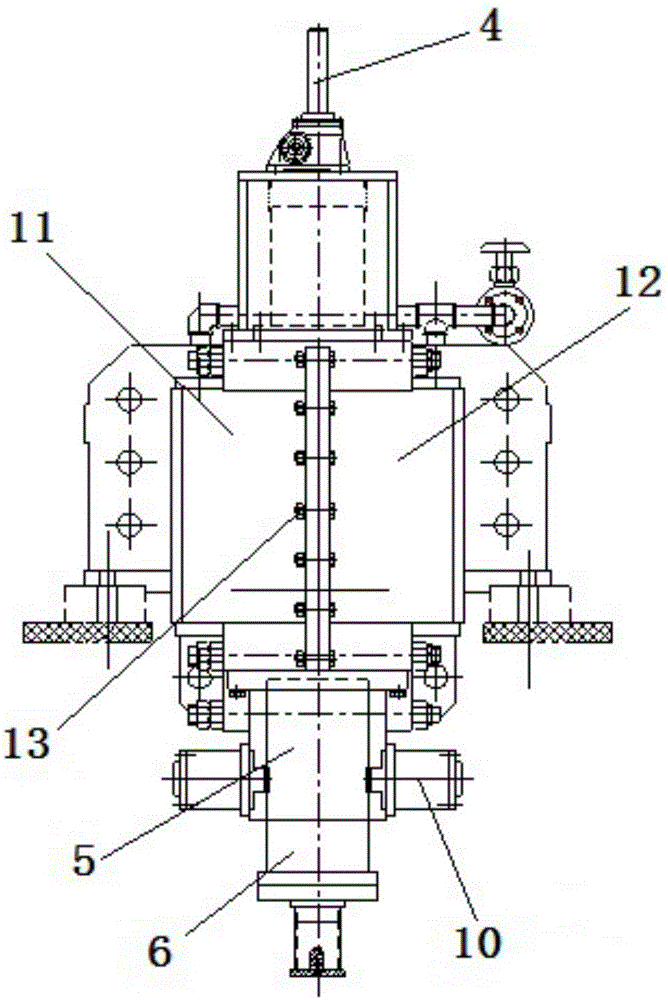

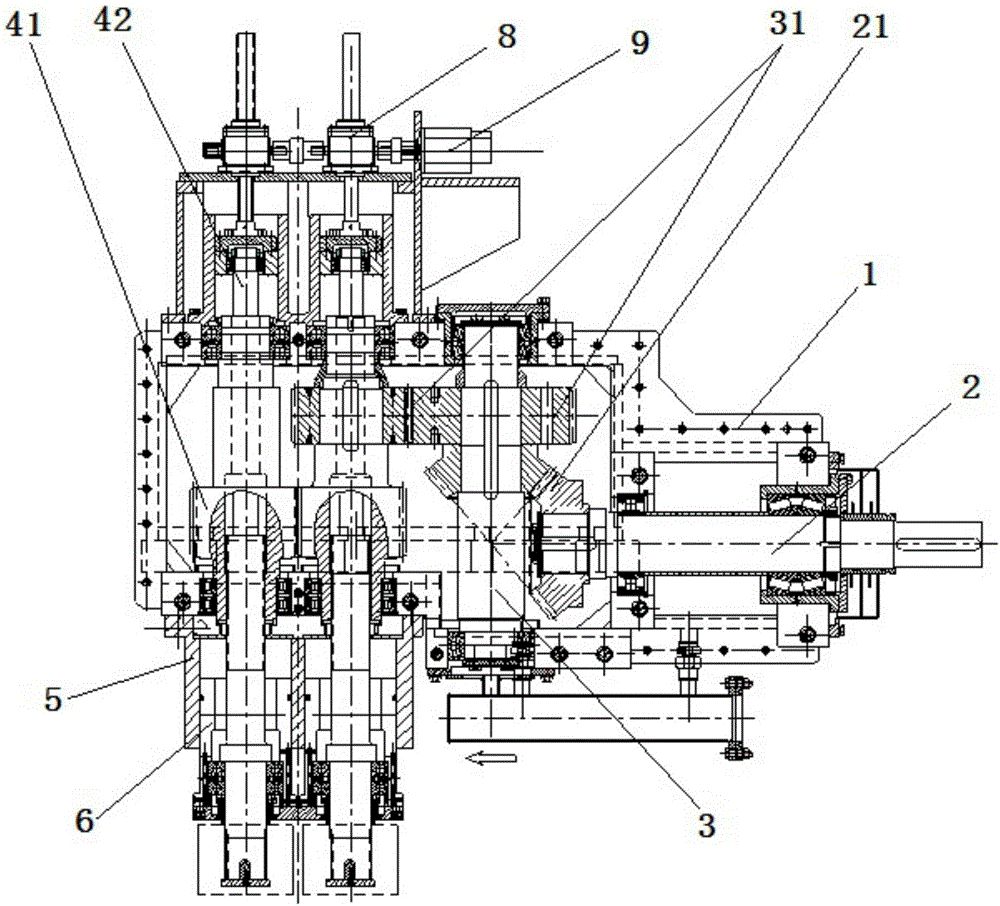

[0028] Please combine Figure 1 to Figure 3 As shown, a vertical intelligent combined gearbox of the present invention, including,

[0029] The box body 1 includes a left box body 11 and a right box body 12, and the left box body 11 and the right box body 12 are connected by bolts 13;

[0030] The input shaft 2 is installed horizontally on one side of the box body 1 for providing power;

[0031] The auxiliary shaft 3 is vertically installed in the box body 1, and is engaged with the input shaft 2 through the bevel gear 21;

[0032] The output shaft 4 is installed vertically in the box body 1 and is located on the side of the auxiliary shaft 3 relative to the input shaft 2. The output shaft 4 and the auxiliary shaft 3 are meshed and connected by a cylindrical gear 31; the output shaft 4 includes an inner output shaft 42 and an outer output shaft. Shaft 41, the upper end of the inner output shaft 42 runs through the outer output shaft 41 and is fixed on the top of the box body...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com