Selective-laser-melting two-dimensional ultrasonic vibration introducing device

A technology of laser selective melting and ultrasonic vibration, which is applied in the directions of additive manufacturing, additive processing, and process efficiency improvement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be further described below in conjunction with the accompanying drawings.

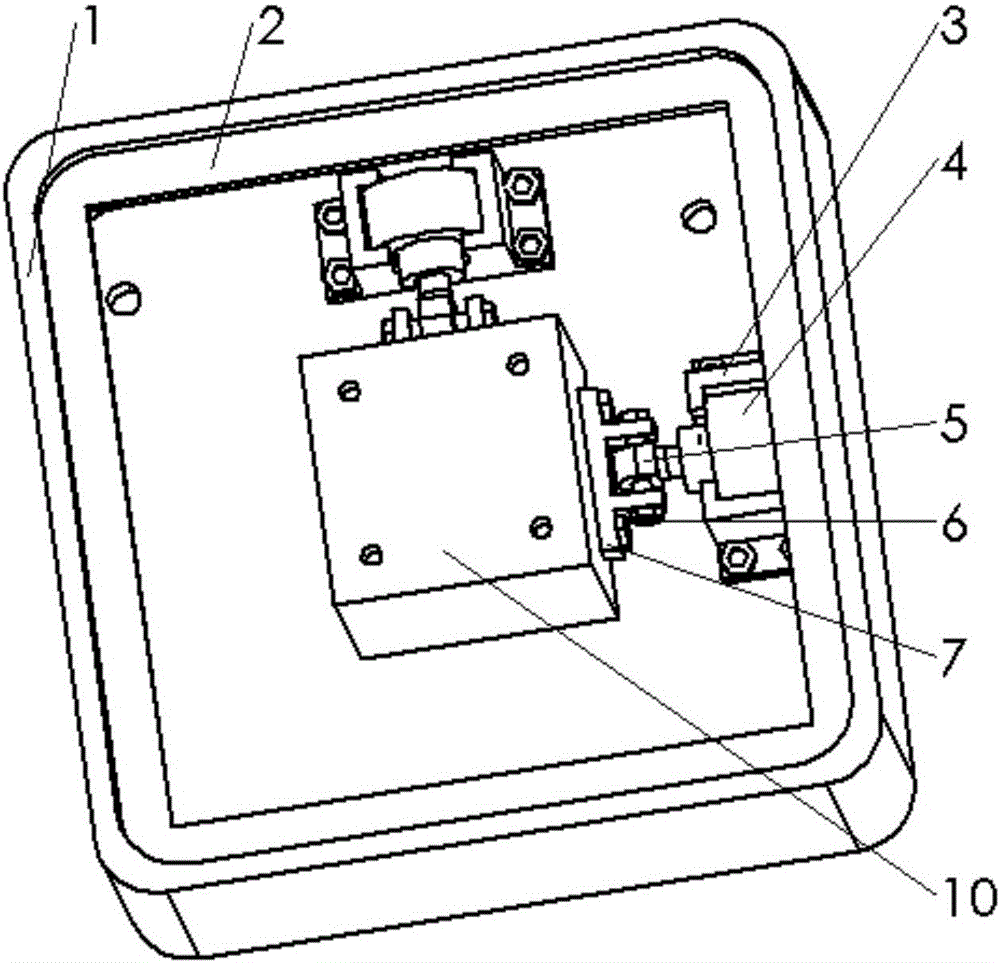

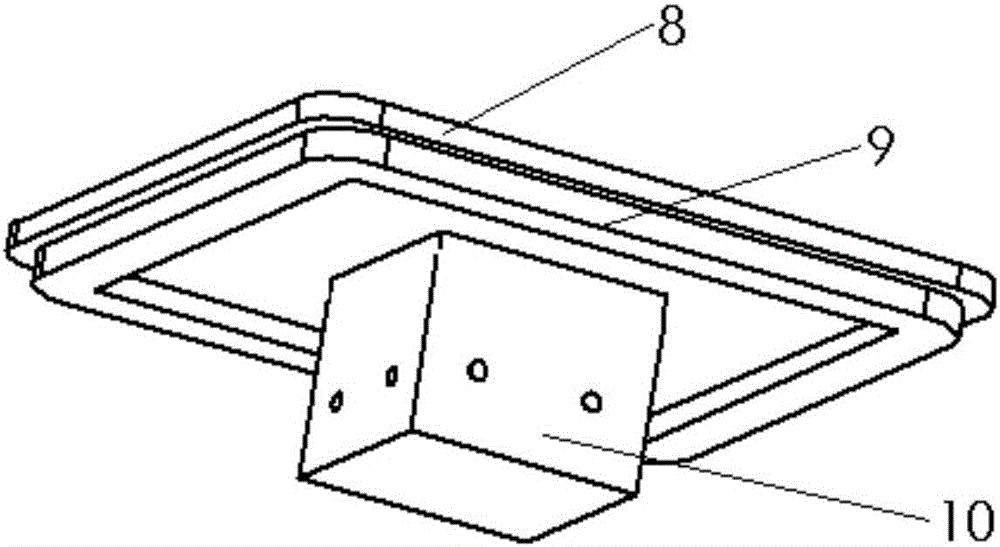

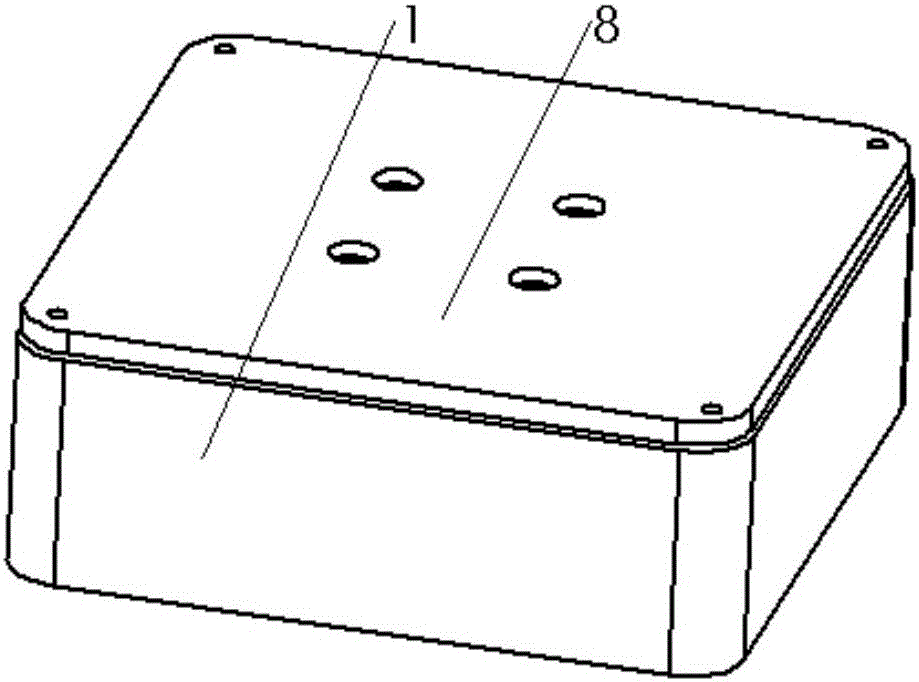

[0013] refer to figure 1 , figure 2 , image 3 , a laser selective melting two-dimensional ultrasonic vibrating device, including a support box 1, the inside of the support box 1 is respectively connected to an ultrasonic transducer fixing base 3 in the X and Y directions, and the ultrasonic transducer fixing base 3 The ultrasonic transducer 4 is fixed on the top, and the ultrasonic transducer 4 is connected to the connecting shaft 6 through the horn 5. The connecting shaft 6 is rigidly connected to the connecting block 7, and the connecting block 7 is screwed to the corresponding side of the counterweight 10. , the counterweight 10 is connected with the lower surface of the ultrasonic vibration platform 8 by screws, a square ring-shaped first support boss 2 is provided inside the support box 1, and square rings are provided on the edges around the lower surface of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com