Double-lifting-appliance bridge crane pivot angle detection system based on holographic photography technology and method thereof

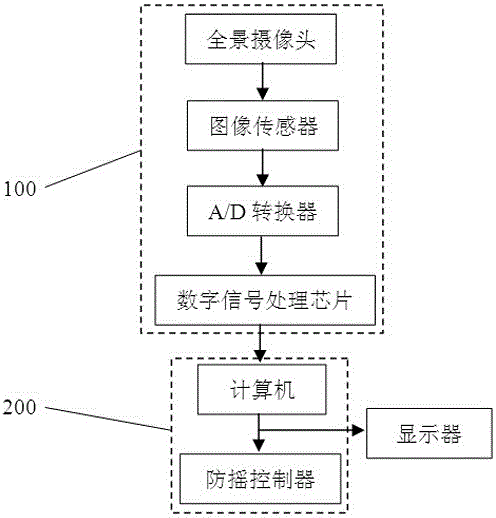

A detection system and panoramic camera technology, applied in the field of visual inspection, can solve problems such as waste of resources, electric field interference, and expensive measuring instruments, and achieve the effects of low price, high measurement accuracy, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The present invention will be further elaborated below by describing a preferred specific embodiment in detail in conjunction with the accompanying drawings.

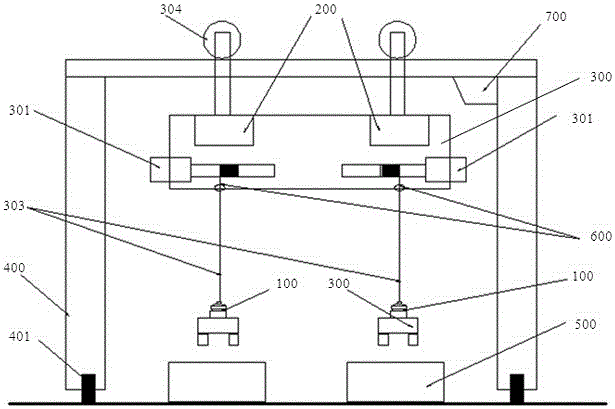

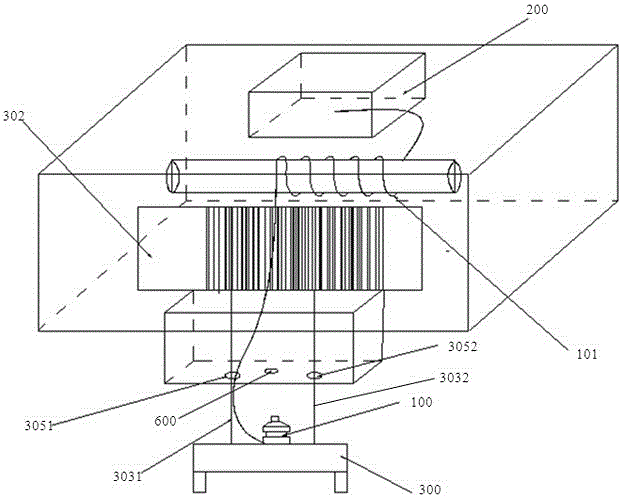

[0046] Such as figure 1 As shown, a double-spreader bridge crane swing angle detection system based on holographic imaging technology is used to detect the swing angle of the double-lift double-sling bridge crane, which includes: a trolley mechanism 300, which is arranged on a cart mechanism 400 Above, it includes a pair of lifting motors 301, each of the lifting motors 301 drives a pair of suspension ropes 303 through a rotating shaft 302, the trolley mechanism 300 is driven by the trolley drive mechanism 304, and the cart mechanism is driven by the cart drive mechanism 401 drive; a pair of suspenders 300, each suspender 300 tops are connected with corresponding pair of suspending ropes 303 respectively; A panoramic camera; a pair of signal processing devices 200, each signal processing device 200 is connected ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com