Small-diameter artificial vascular graft preparation method based on electrostatic spinning

A technology for electrospinning and artificial blood vessels, which is used in the preparation of spinning solutions, blood vessels, textiles, and papermaking, etc., and can solve problems such as the inability to prepare small-diameter artificial blood vessels.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

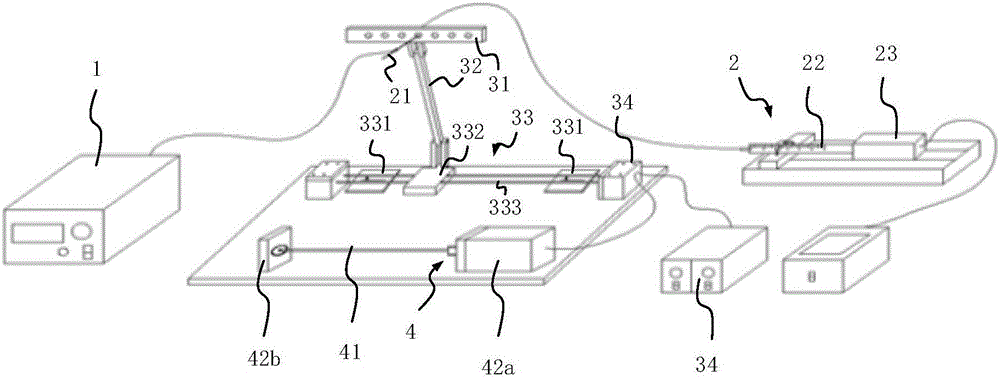

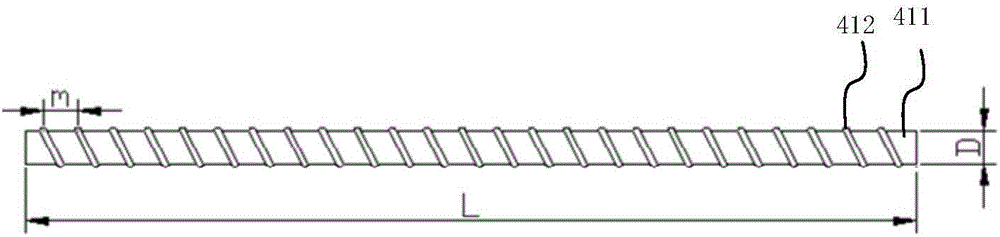

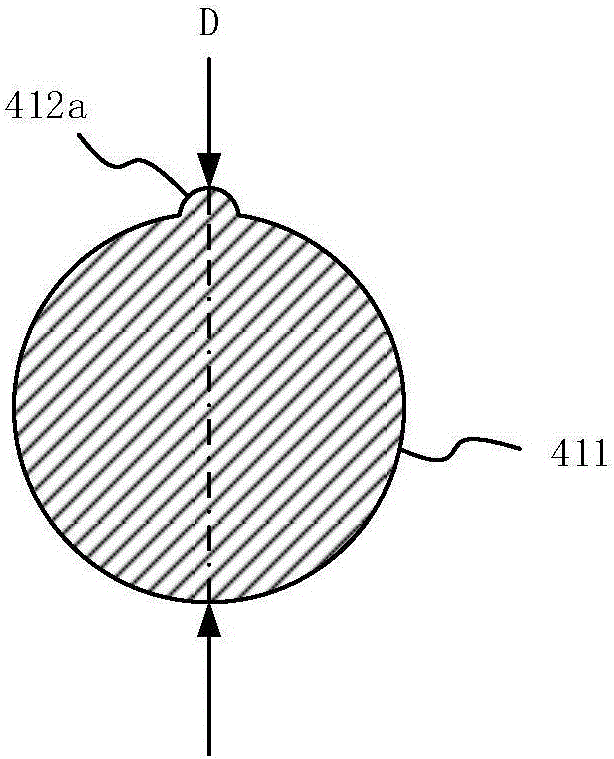

[0041] Please refer to 1, which is a schematic diagram of the principle of a small-diameter artificial blood vessel preparation device based on electrospinning provided by the present invention, and the device will be described in detail below.

[0042] As shown in the figure, the device includes a high-voltage power supply device 1, a spinning solution injection device 2, a receiving device 4, and an injection slide control device 3, wherein the high-voltage power supply device 1 is used to output at least one high-voltage power supply including positive and negative polarities The spinning solution injection device 2 includes an injection device 22 for containing the spinning solution and an injection flow control device 23 for regulating and controlling the injection device 22 to output the spinning solution flow rate, and is used to inject the spinning solution in the injection device 22 according to the injection The regulation and control of the flow control device 23 is ...

Embodiment 2

[0061] In addition, in this embodiment, the present invention also provides a method for preparing artificial blood vessels through the device provided in Embodiment 1, please refer to Figure 5 , provides a flow chart of a method of using the device in Example 1 to realize the preparation of artificial blood vessels, and the implementation steps of the method will be described in detail below.

[0062]Step S10, use an electronic balance to weigh 0.4g of L-lactic acid and ε-caprolactone copolymer (P(LLA-CL)) [full name: Poly(L-lactide-co-epsilon-caprolactone)], the molar ratio is 50 :50, dissolved in 5ml of hexafluoroisopropanol (linear molecular formula: (CF3) 2CHOH), stirred and oscillated by a magnetic stirrer until the dissolution is complete, generally the rotating speed of the magnetic stirrer is set to 300rpm, and the concentration obtained is 8% ( g / ml) of the electrospinning solution;

[0063] Step S20, put the electrospinning solution into the spinning solution inje...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com