Special bracket for construction of whole bilateral post-poured flange plate and application method thereof

A flange plate and integral technology, applied in the direction of erecting/assembling bridges, noise absorbing devices, bridges, etc., can solve the problems of increased safety hazards, large construction interference, increased workload, etc., to shorten the construction period and reduce construction costs. cost, construction safety and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with the embodiments and accompanying drawings.

[0026] The technical scheme of special support of the present invention is:

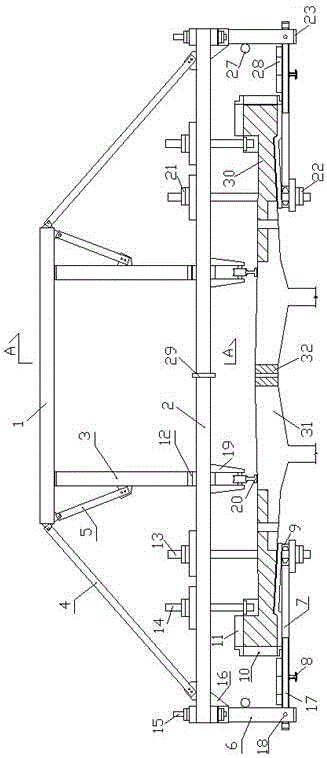

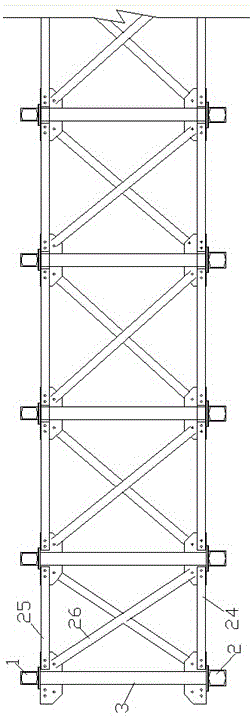

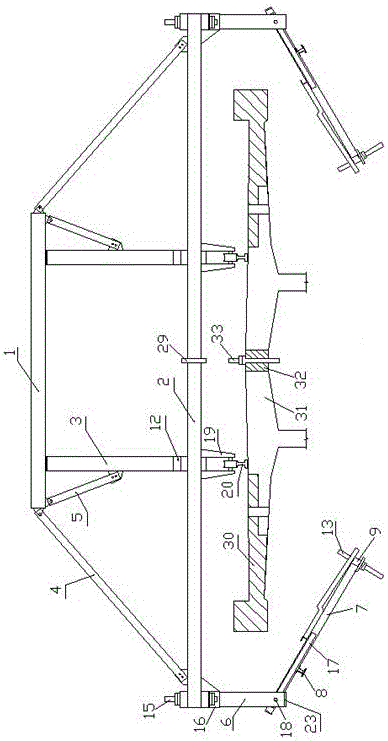

[0027] The two sides between the connecting beam 1 and the main beam 2 are respectively connected to the support column 3 through the flange 12, and the long diagonal stays 4 are respectively fixed on both sides of the end of the connecting beam 1 and the end of the main beam 2, and the two sides of the connecting beam 1 The short stays 5 are respectively fixed to connect with the supporting columns 3, the left and right ends of the main girder 2 are respectively provided with lower frame plates 16 and are connected to the suspenders 6 through the connecting straps 15, and a limit baffle 23 is provided at the lower part of the suspenders 6 to hang The column 6 is hinged with the reinforcement plate 17 through the hinge shaft 18, the reinforcement plate 17 is connected to the b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com