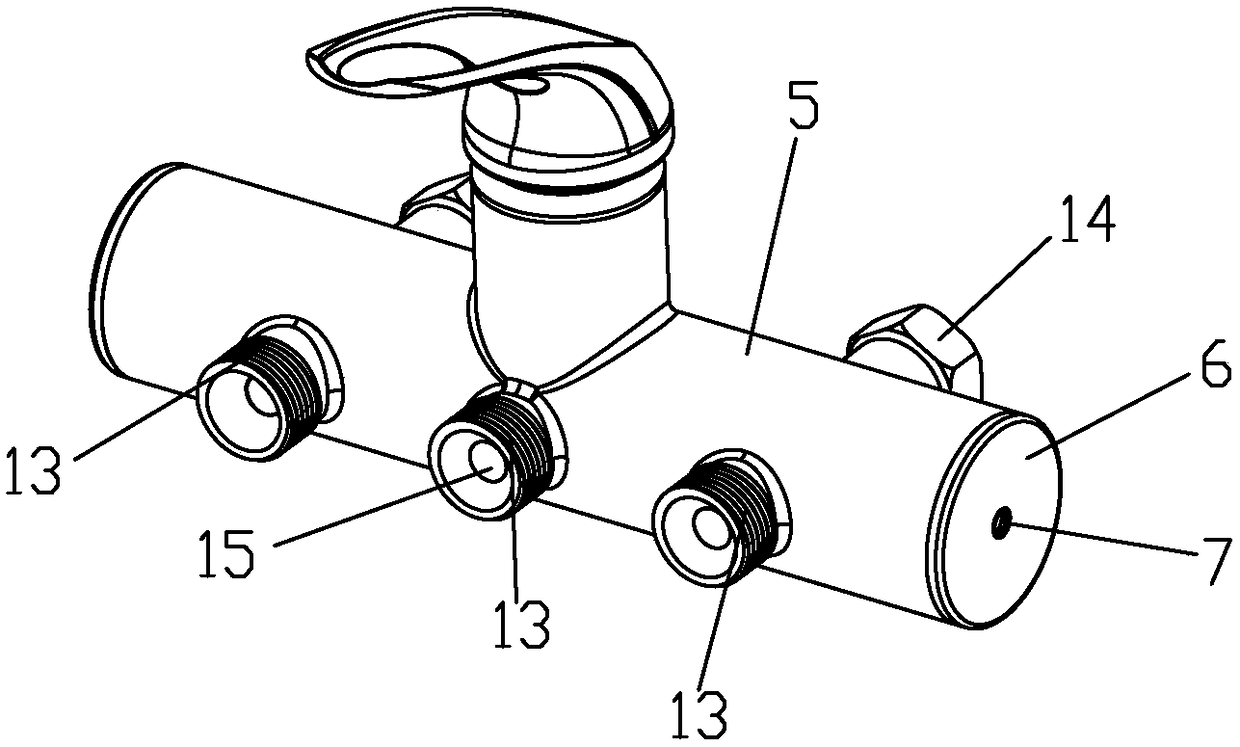

A multifunctional water mixing valve with an electric partition wall

A multi-functional, water-mixing valve technology, applied in multi-way valves, valve details, valve devices, etc., can solve the problems of low utilization rate of waterway box structure space, high cost of metal materials, and easy water pollution, etc. Easy to get dirt, high space utilization, uniform force effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

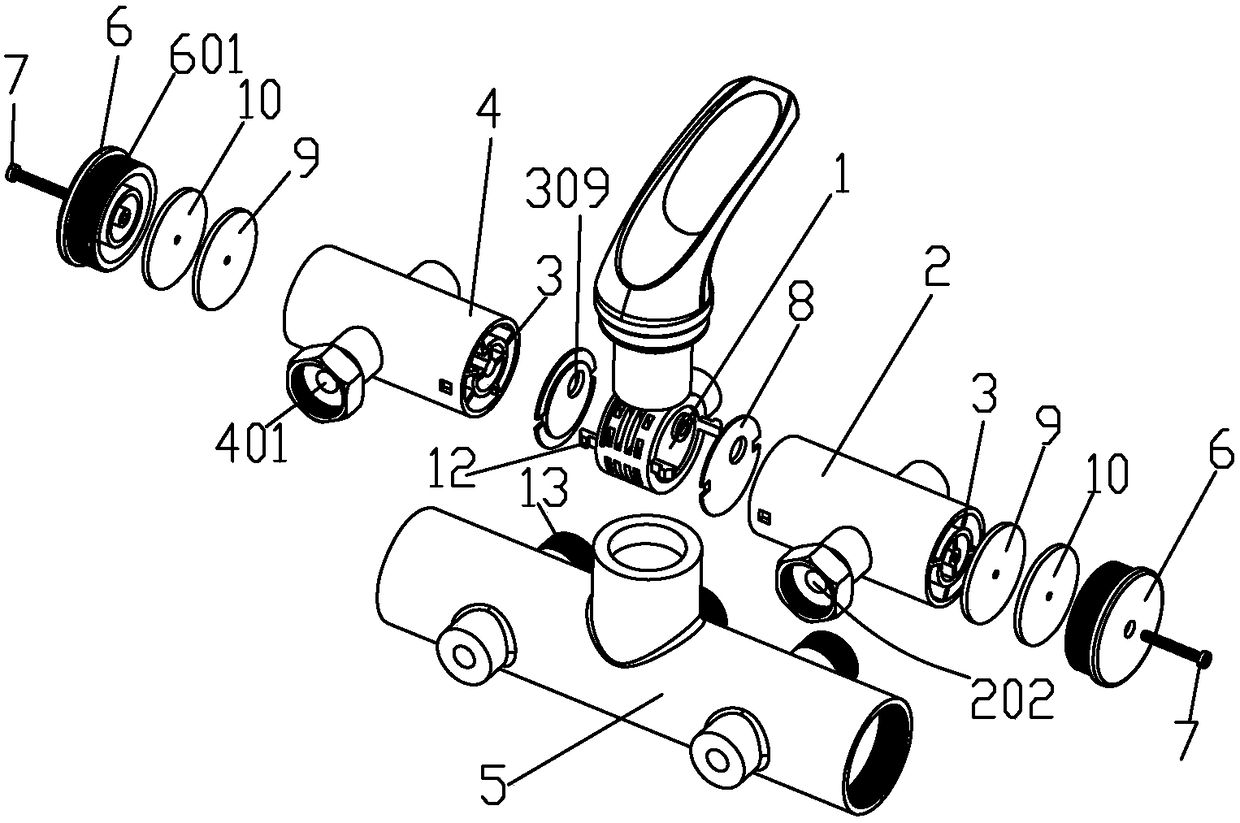

[0044] The working process of the first embodiment is as follows: Figure 5 As shown, the water flow enters the water inlet pipe 2 from the cold water inlet 201 and is divided into two branches, one of which goes half a circle in the forward direction into the outlet hole 202 of the inlet pipe and enters the water heater to be heated. A communicating hole 309 enters the valve core seat communicating body 1; the heated hot water enters the outlet pipe 4 from the inlet hole 401 of the outlet pipe, such as Figure 4 As shown, the hot water that enters the outlet pipe 4 is divided into two branches after traveling half a circle of the electricity isolation water channel. One branch flows out from the hot water outlet hole 402, and the other one completes the other half circle of the electricity isolation water channel and then passes through the first connecting hole. 309 enters the valve core seat communicating body 1 and mixes with cold water and flows out from the mixing water out...

Embodiment 2

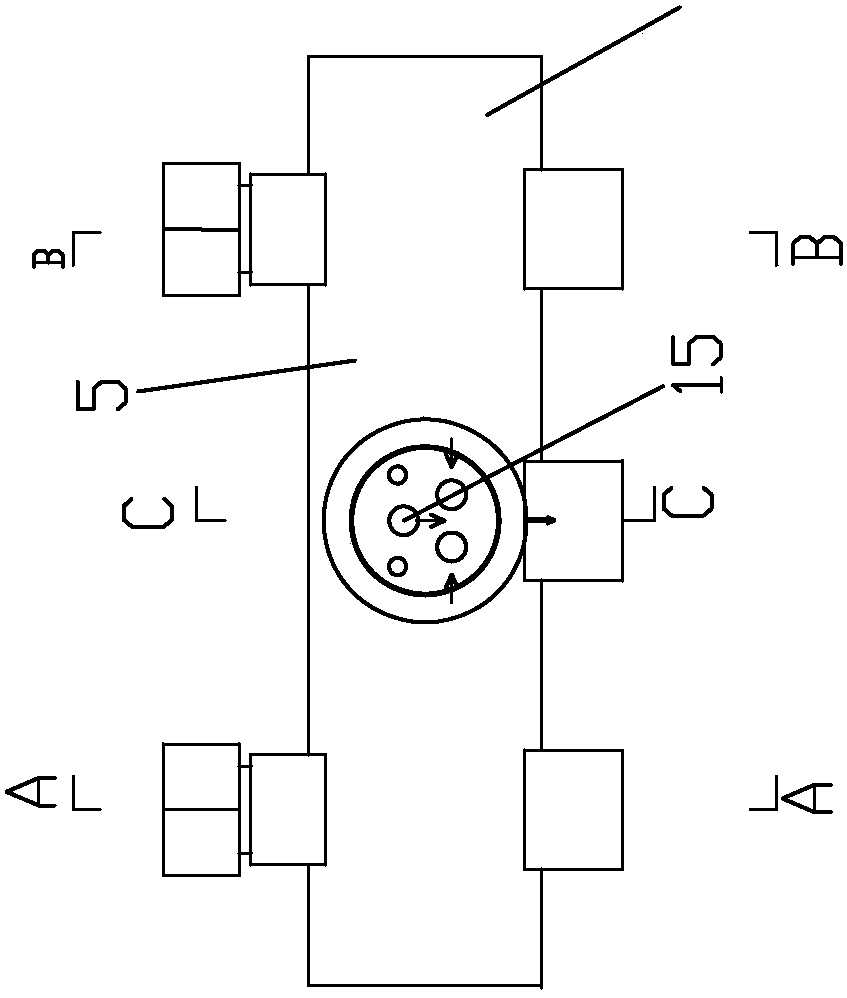

[0045] The second embodiment is a two-layer electrical isolation water channel: such as Figure 7 to Figure 10 As shown, the water inlet pipe 2 and the water outlet pipe 4 are provided with an inner pipe 303 coaxially arranged with the water pipe to separate the water pipe cavity into an outer cavity and an inner cavity, on the inner wall of the water pipe and the outer wall of the inner pipe 303 There are a plurality of second partitions 305 radially dividing the outer cavity into a plurality of sub-outer cavities, and a plurality of blocks are radially arranged inside the inner tube 303 to divide the inner cavity into a plurality of sub-inner cavities. The third partition 307 of the cavity, the third partition 307 is fixed between the inner wall of the inner tube 303 and the central column 11, the two ends of the water inlet pipe 2 and the water outlet pipe 4 are sealed and further the second partition 305. The two ends of the third partition 307 are sealed, and at the end of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com