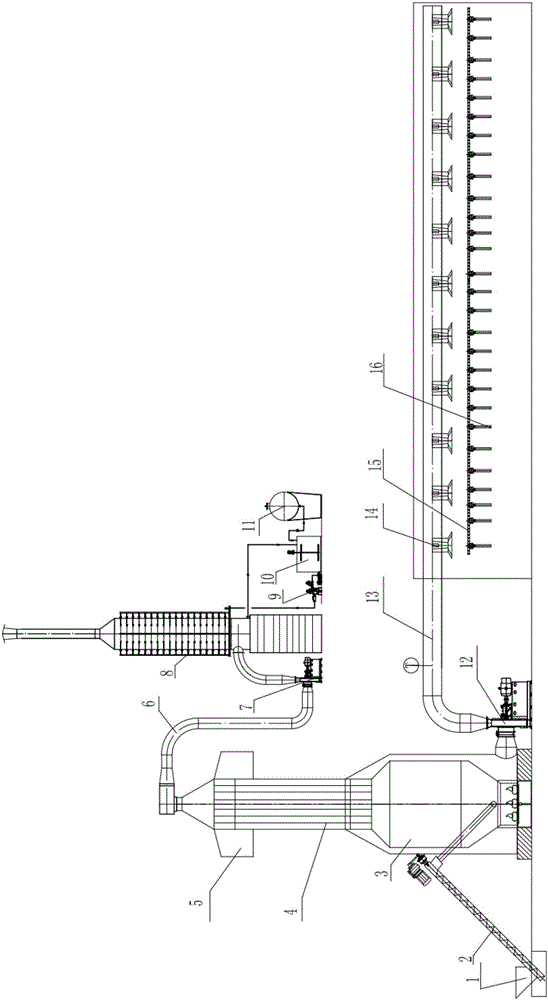

Vermicelli drying device

A drying device and vermicelli technology, applied in the direction of drying gas arrangement, progressive dryer, drying solid materials, etc., can solve the problems of low production efficiency, long drying time, waste of energy, etc., to save heat medium cost and shorten drying time , Improve the effect of drying strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

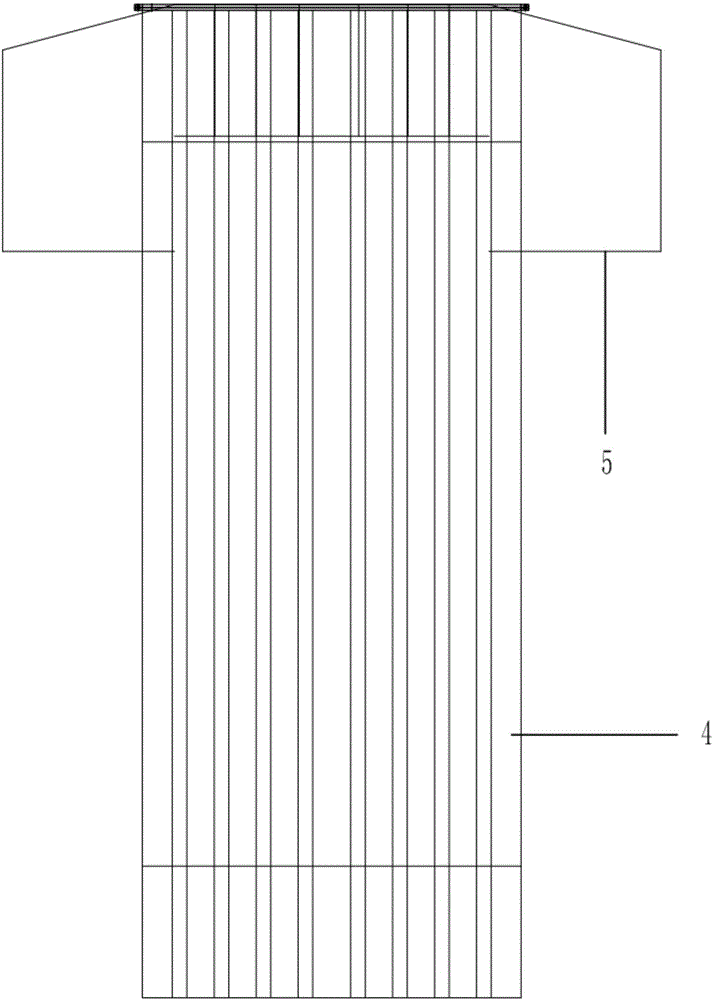

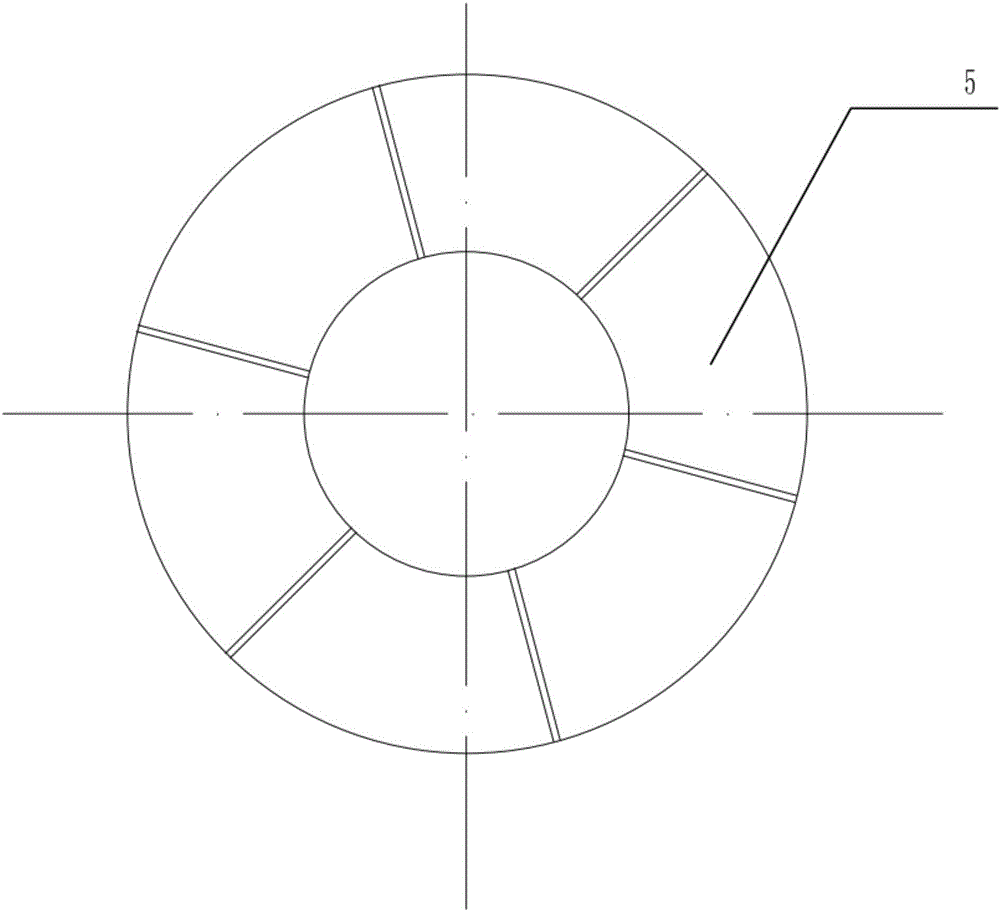

[0026] Such as Figure 7 As shown, the drying room of the vermicelli drying device is divided into four areas, each area is 60m in length, and each area is equipped with a temperature and humidity control system. The temperature in the drying area is controlled at 10°C, and the humidity is 60-70%. Wind intensity 100m per square meter 3 , the wind cutting speed is 2-3m / s. The first area is mainly to shape the vermicelli. The temperature and wind intensity should not be too high to prevent the deformation of the vermicelli. The second area is a stable area. Strength is 150m per square 3 , the cutting wind speed is 2-3m / s; the third area is the dehydration area, the temperature is controlled at 20°C, the humidity is controlled at 30-45%, the wind cutting speed is 3-5m / s, and the wind intensity is 250m per square meter 3 , The wind cutting speed is 3-5m / s, which is equivalent to the speed of the natural second and third winds. The fourth area is the cooling area, the temperatur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com