Stratified sampling device for liquid and method for performing stratified sampling on liquid

A sampling device and liquid sample technology, applied to the sampling device and other directions, can solve the problems of inconvenient carrying and storage, complicated operation, affecting observation effects, etc., and achieve the effects of easy carrying and storage, high sampling accuracy, and convenient disassembly and assembly.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

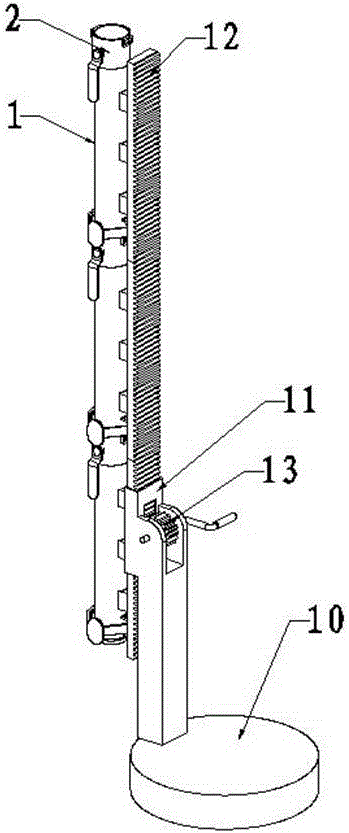

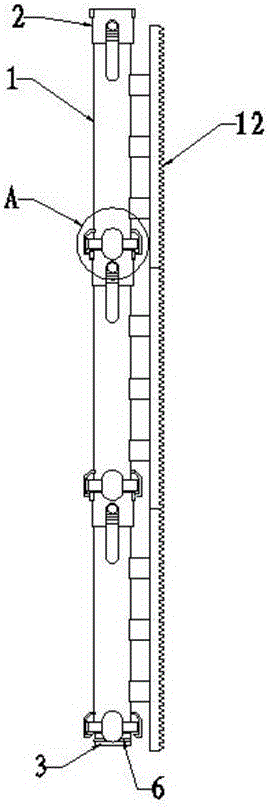

[0029] In order to clearly illustrate the technical features of this solution, the specific implementation of the present invention will be further described below according to the accompanying drawings.

[0030] As shown in the figure, a liquid layered sampling device includes a sampling tube and a sampling bracket. The sampling tube includes three sampling tube units. The sampling tube unit includes a tube body 1 and a stop valve 2. The tube body 1 is made of a transparent material. The outer circular surface of the pipe body 1 is provided with a scale line parallel to its axial direction (not shown in the figure), and the lower end of the shut-off valve 2 is fixedly connected with the upper end of the pipe body 1 by sealing pipe threads.

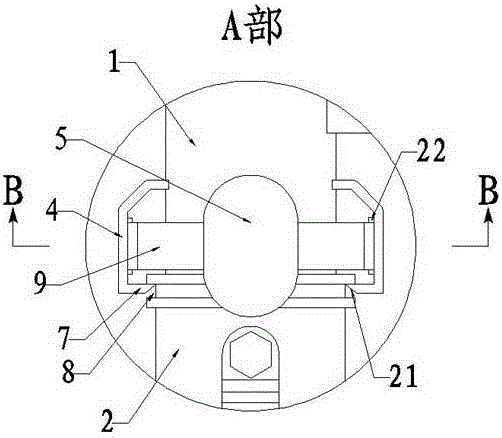

[0031] The lower end of the pipe body 1 and the upper end of the cut-off valve 2 are provided with a matching sealing connection mechanism, the sealing connection mechanism includes an insertion part 3, an elastic clamping arm 4 and an unl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com