Layout structure of combined photomask as well as formation method and application method for layout structure

A technology of layout structure and photomask, which is applied in the photoplate making process of the pattern surface, the original for photomechanical processing, optics, etc., can solve the problem of not being able to obtain rectangular holes or rectangular islands, and achieve simple structure and increase the number of windows , to meet the effect of resolution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047]The layout structure of a combined photomask proposed by the present invention and its forming method, as well as the application of the combined photomask in semiconductor manufacturing, will be described in further detail below with reference to the accompanying drawings and specific embodiments. Advantages and features of the present invention will be apparent from the following description and claims. It should be noted that all the drawings are in a very simplified form and use imprecise scales, and are only used to facilitate and clearly assist the purpose of illustrating the embodiments of the present invention.

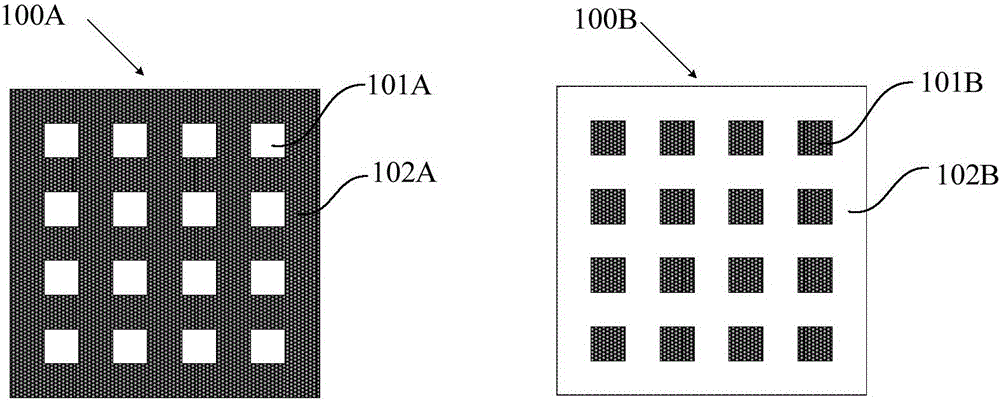

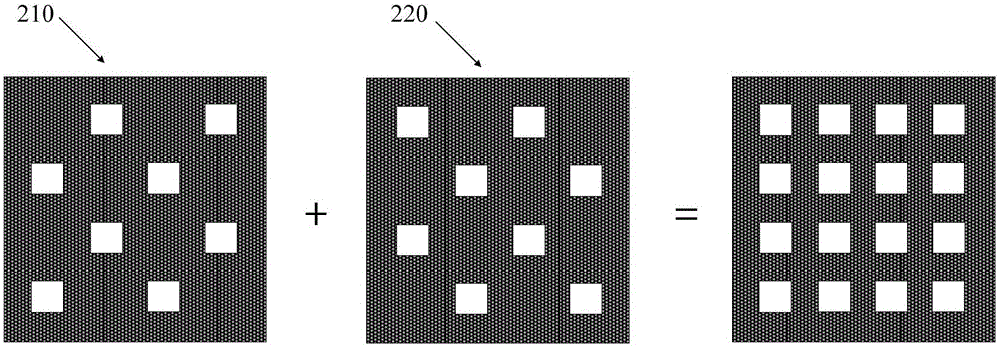

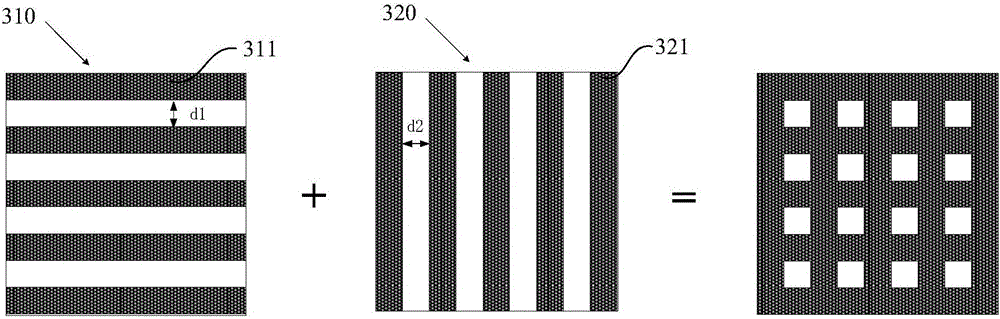

[0048] The invention provides a layout structure of a combined mask, which can form a rectangular hole or a rectangular island on a semiconductor substrate even under the influence of the optical proximity effect; When hole arrays or arrays are used, the resolution required for dense graphics can be met by using the combined mask provided by the present ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com