Difference signal pair twist structure USB3.1 wire and manufacture method therefor

A USB3.1, differential signal pair technology, used in cable/conductor manufacturing, cables with double-stranded/quad-stranded, conductors, etc., can solve the problem of unstable electrical performance, high electronic processing costs, and processing The problem of high cost is to achieve the effect of low wire processing cost, low electronic processing cost and stable electrical performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

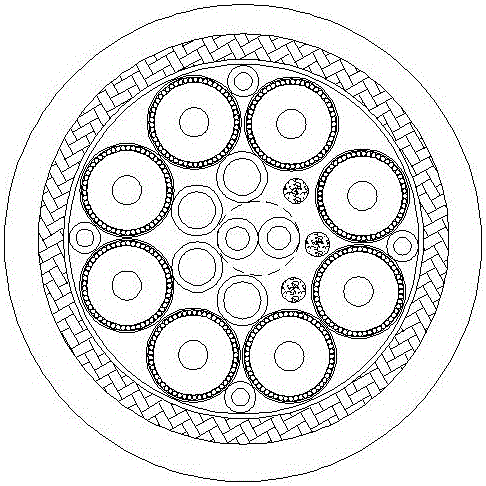

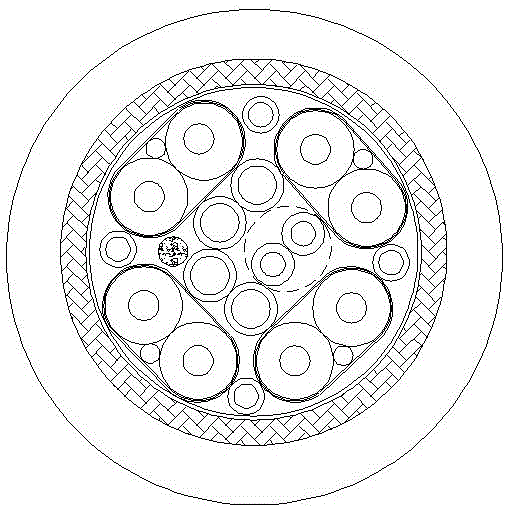

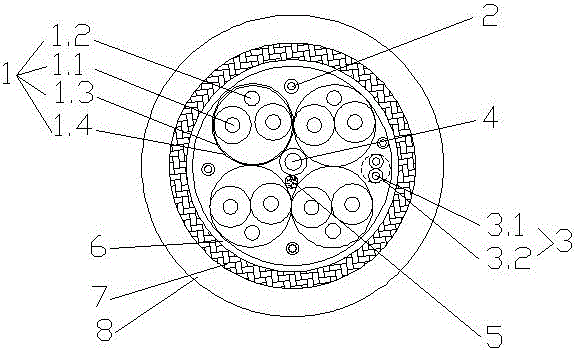

[0037] see image 3 , the present invention relates to a USB3.1 cable with differential signal pair structure, which includes an internal structure and an outer shielding layer 6, a braiding layer 7, and a sheath layer 8 that are sequentially arranged outwards in the internal structure, and the internal structure includes four first Signal wire 1, four electronic wires 2, a second signal wire 3, a power wire 4 and a filler wire 5, among which the four first signal wires 1 are arranged in matrix two by two, and one power wire 4 and a filling line 5 are located in the gaps inside the four first signal lines 1, the four electronic lines 2 are respectively located in the gaps outside the four first signal lines 1, and a second signal line 3 is located in two of them In the gap outside the first signal line 1.

[0038] in:

[0039] The first signal line 1 includes a first signal line central body and a first signal line shielding layer 1.1 and a first signal line shielding layer ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com