Electricity safety system with impurity eliminating function, for winder operating room

A safety system and winder technology, applied in electrical components, substation/distribution device casing, substation/switch layout details, etc., can solve the problems of abnormal operation, difficult operation, influence, etc., and achieve the effect of enhancing the cooling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Below in conjunction with accompanying drawing, content of the invention will be further described:

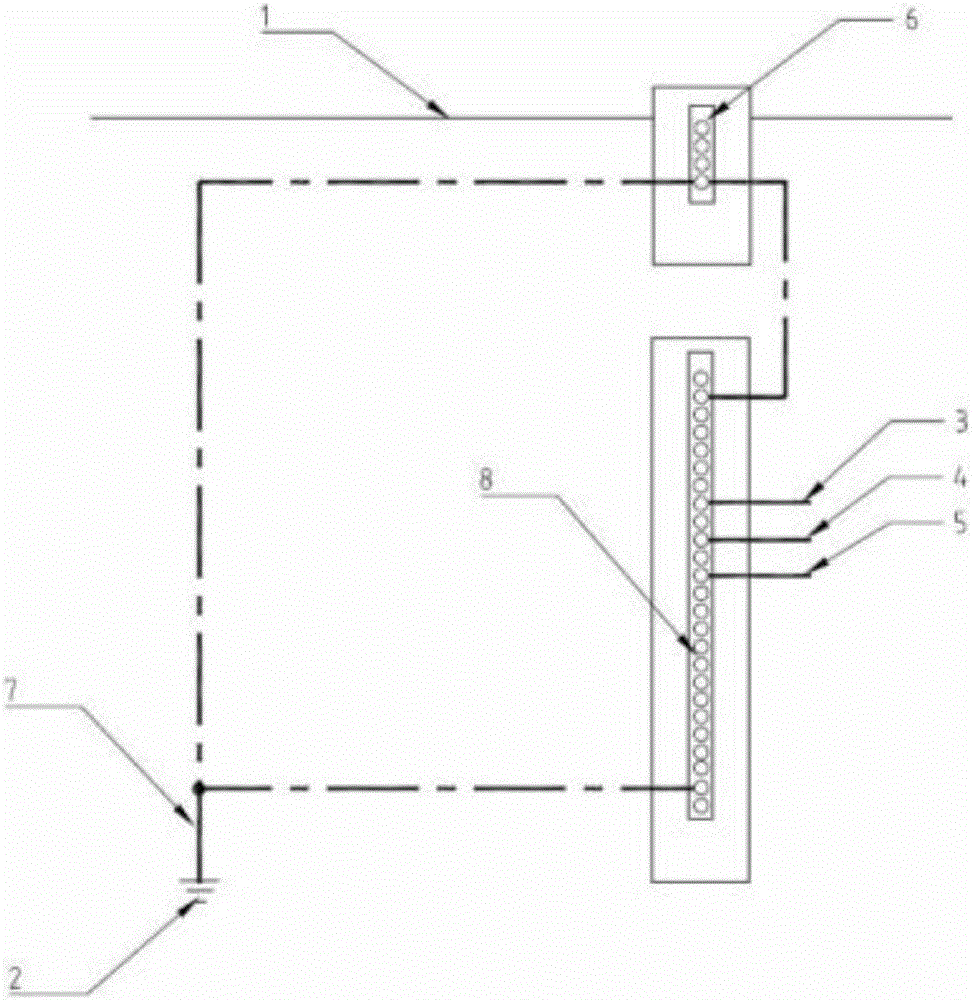

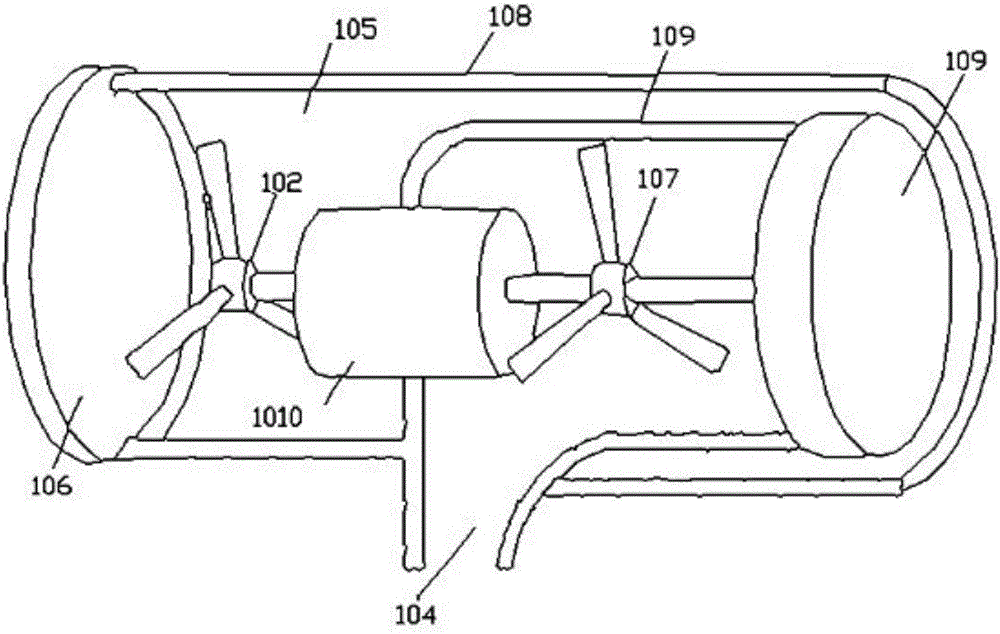

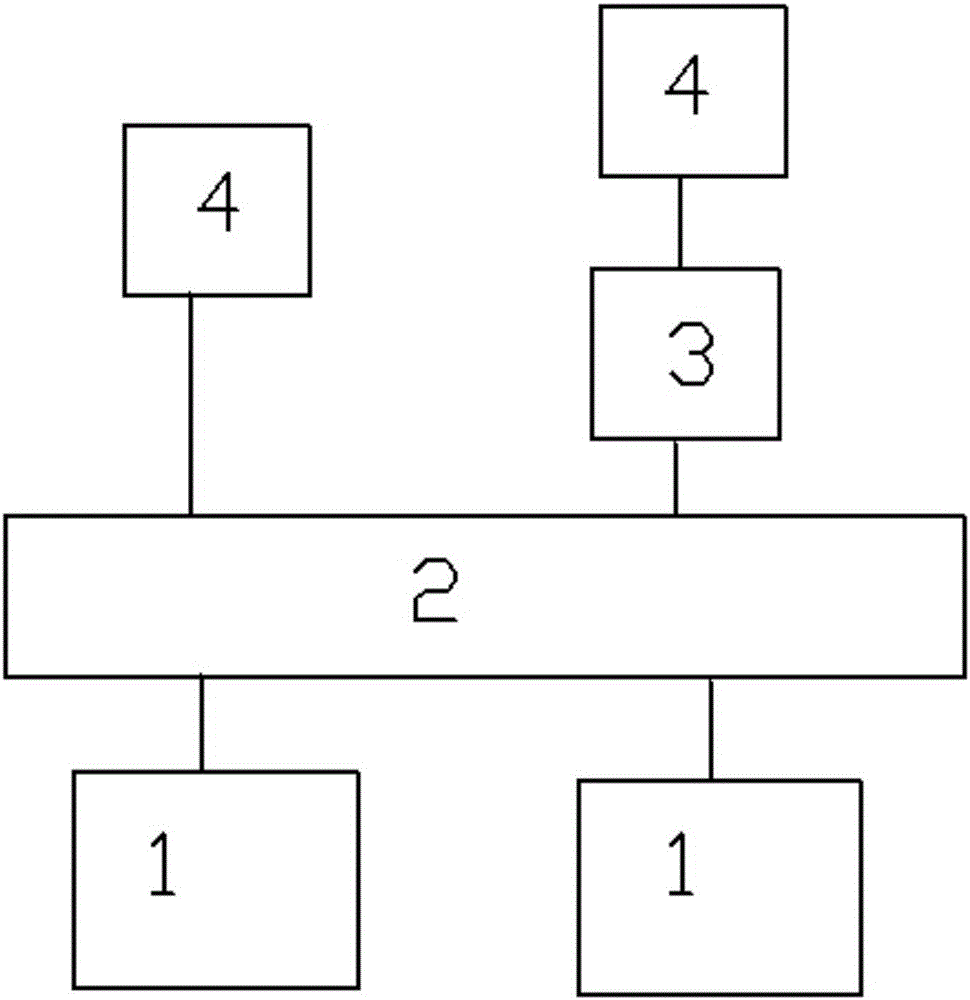

[0024] refer to Figure 1-Figure 7As shown, the electrical safety system for the winding machine working room with the function of removing impurities, including the main box for incoming wires, bus loop 1, grounding ring network 2, basic steel ring network, metal pipes, Metal decorations, strong and weak current inlet pipes and cable armor sheaths, among which there is a PE row 6 in the cable inlet box, and the PE row 6 is conductively connected to the basic steel bar 7 connected to the grounding ring network 2. There is a general equipotential bonding box 8 beside the general box, and metal pipes 4, metal decorative parts 5, the outer wall of the strong and weak current inlet pipe and the cable armor sheath 3 are all connected to the general equipotential bonding through the general equipotential bonding line box, and the general equipotential bonding box is connecte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com