Method for improving beef quality by gradually cooling beef carcasses

A technology for gradually cooling and beef carcass, applied in the field of gradually cooling beef carcass to improve beef quality, can solve the problems of application limitation and increase microbial risk, and achieve the effect of improving meat quality, shortening maturation time, and avoiding cold shrinkage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Below in conjunction with embodiment, further set forth the present invention:

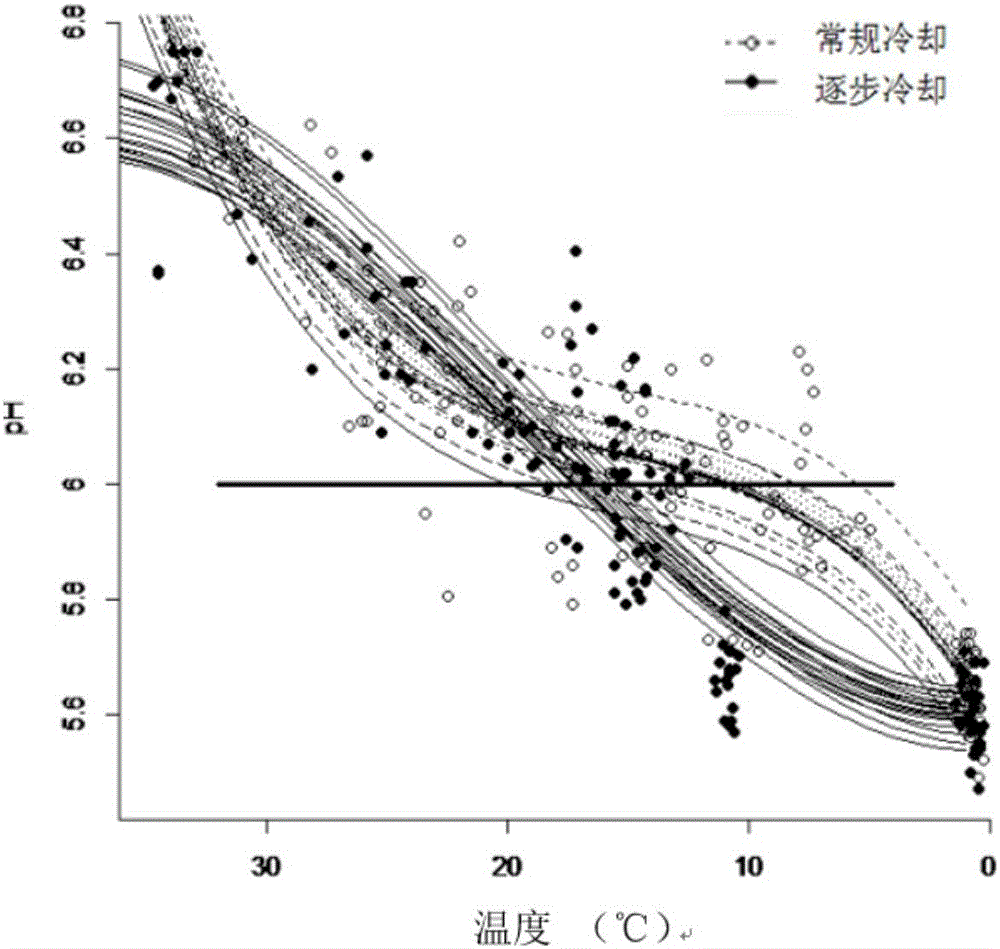

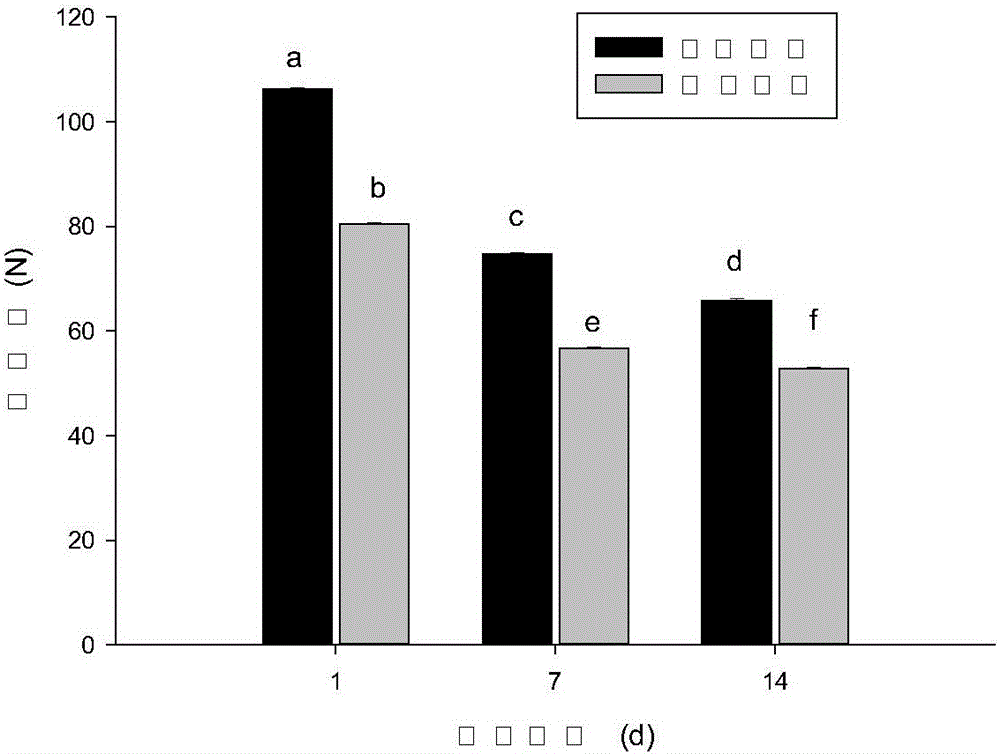

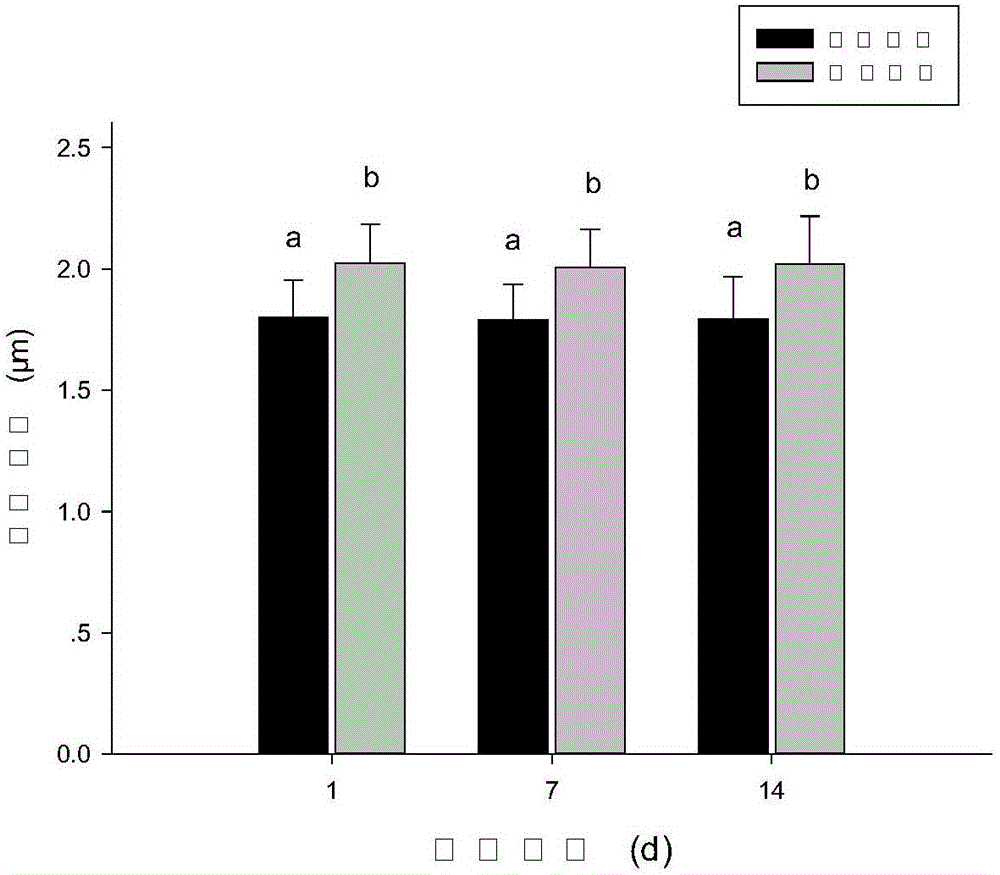

[0019] 18 hybrid cattle (Luxi Cattle×Simmental, weight before slaughter 493.8±60.3kg) with similar body weight at about 24 months were selected for conventional cooling and gradual cooling respectively. The experimental design was as follows: conventional cooling: each cow The left half-carcass of the cow is pushed into the conventional cooling room (air temperature 1±1°C, air velocity 0.5m / s) until 48 hours after slaughter; gradual cooling: the right half-carcass of the same cow corresponding to the conventional cooling is pushed into another Quickly cool in the cooling room for 2 hours (air temperature -11±1°C, air flow rate 0.5m / s), stop cooling (air flow rate 0m / s) to keep the center temperature of the longissimus dorsi at 12-18°C until 10 hours after slaughter, Then push it into the conventional cooling room (1±1°C, air flow rate 0.5m / s) until 48 hours after slaughter; after that, divi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com