Ultrasonic cleaning machine

A cleaning machine and ultrasonic technology, applied in cleaning methods and utensils, cleaning methods using liquids, chemical instruments and methods, etc., can solve the problems of low space utilization rate and low energy utilization rate, so as to improve energy utilization rate, The effect of improving heating efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The specific embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

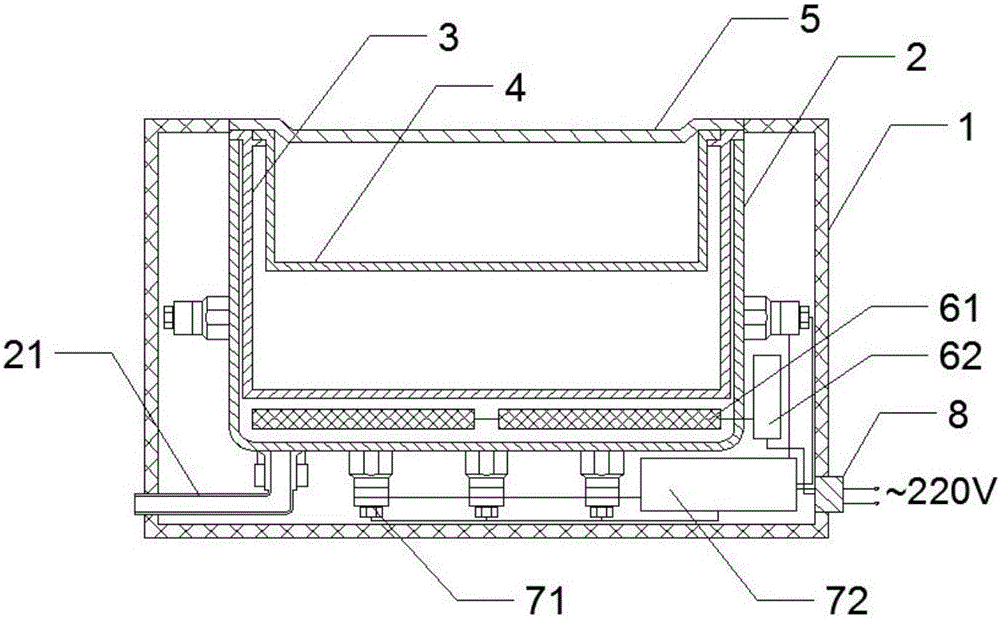

[0019] like figure 1 The shown ultrasonic cleaning machine includes a casing 1, a cleaning tank 2, a water outlet 21, a metal basket 3, a metal interlayer basket 4, a slot cover 5, a heater 61, a heater controller 62, a transducer 71, an ultrasonic Frequency power supply 72, socket 8;

[0020] The housing 1 is the frame of the whole equipment, the cleaning tank 2 is installed in the housing 1, and the drain port 21 is arranged at the bottom of the cleaning tank 1; the transducer 71 is bonded to the outer bottom wall of the cleaning tank 2; the transducer 71 is connected to the ultrasonic The frequency power supply 72, the ultrasonic frequency power supply 72 is connected to the socket 8, and the socket 8 is powered by 220V alternating current;

[0021] The heater 61 is installed in the cleaning tank 1, close to the bottom; the heater 61 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com