Oil seal device convenient to measure oil pressure of oil cavities of vertical ultraprecise static-pressure guide rail

A static pressure guide rail, ultra-precision technology, applied in the direction of measuring/indicating equipment, large fixed members, maintenance and safety accessories, etc., can solve the problems of non-adjustable throttling ratio, troublesome disassembly and assembly, etc., and achieve simple and compact structure, The effect of convenient oil pressure detection and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

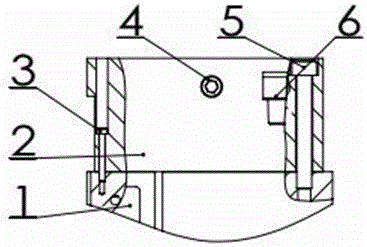

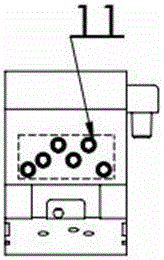

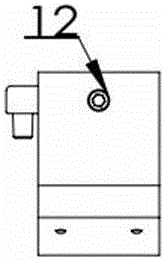

[0015] The structure diagram of the present invention is as figure 1 , 2 , 3, and 4, the vertical ultra-precision static pressure guide rail oil chamber oil pressure measuring oil seal device of the present invention includes a slide table 1, an oil seal 2, a first connecting piece 3, a second connecting piece 5, and a first communicating hole Sealing plug 4, oil inlet joint 6, sealing ring 7, throttle 8, oil pressure measuring hole sealing plug 9, capillary installation hole sealing plug 10, second communication hole sealing plug 11, third communication hole Sealing plug 12, wherein the first connecting piece 3 and the second connecting piece 5 connect the oil seal 2 and the slide table 1 together; the seal ring 7 is installed between the oil seal 2 and the slide table 1 to play a sealing role; the oil pressure The holes connected to the sealing plugs 9 of the measuring holes run through the oil seal 2 and communicate with the six oil chambers of the slide table 1 respective...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com