Jet-type steel pipe surface concrete and rust removal device and removal method

A concrete and jet technology, applied in chemical instruments and methods, cleaning methods and utensils, abrasive feeding devices, etc., can solve the problems of consuming a lot of water resources, affecting the working environment, and accumulating water in the working place, and reducing manpower. The effect of material resources investment, improving removal efficiency and improving operating conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

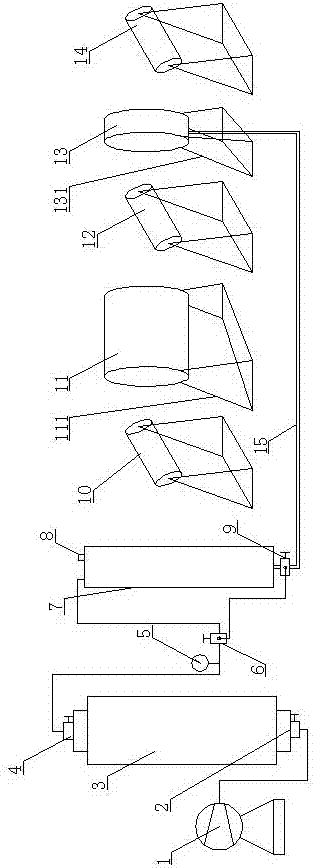

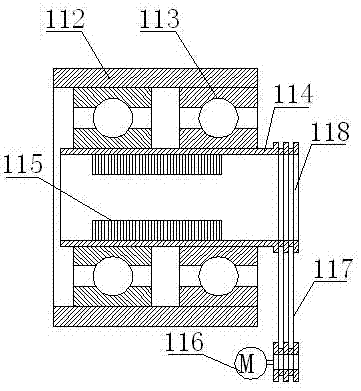

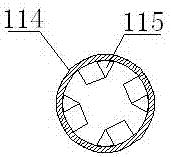

[0030] Such as Figure 1-Figure 5 The shown jet-type steel pipe surface concrete and rust removal device includes an air compressor 1, a high-pressure gas cylinder 3 and an abrasive tank 7, an abrasive filling inlet 8 is arranged at the upper end of the abrasive tank 7, and the air compressor 1 passes through a pipeline and a high-pressure gas The inlet valve 2 of the bottle 3 is connected, and the gas outlet valve 4 of the high-pressure gas cylinder 3 is provided with a gas three-way valve 6 through a pipeline. The pipeline is used to pressurize the abrasive tank 7, and the pipeline at the lower end is used to mix the abrasive with the gas and transport it to the nozzle 133; It can ensure the smooth downward flow of abrasives; when the abrasives are used up, close the air outlet valve 4 to quickly add abrasives to improve work efficiency. A pressure gauge 5 is provided between the gas outlet valve 4 and the gas three-way valve 6 for easy observation of the system pressure. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com