Constant-temperature and constant-pressure permo-treatment method and device for ultra-clean insulation material

An insulating material, constant temperature and constant pressure technology, applied in the field of constant temperature and constant pressure permeation treatment of ultra-clean insulating materials, can solve the problems of increasing the production cost of raw material manufacturers, unable to guarantee the vacuum degree, waste of raw materials, etc., to ensure process stability, guarantee Cleanliness, anti-oxidative discoloration effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

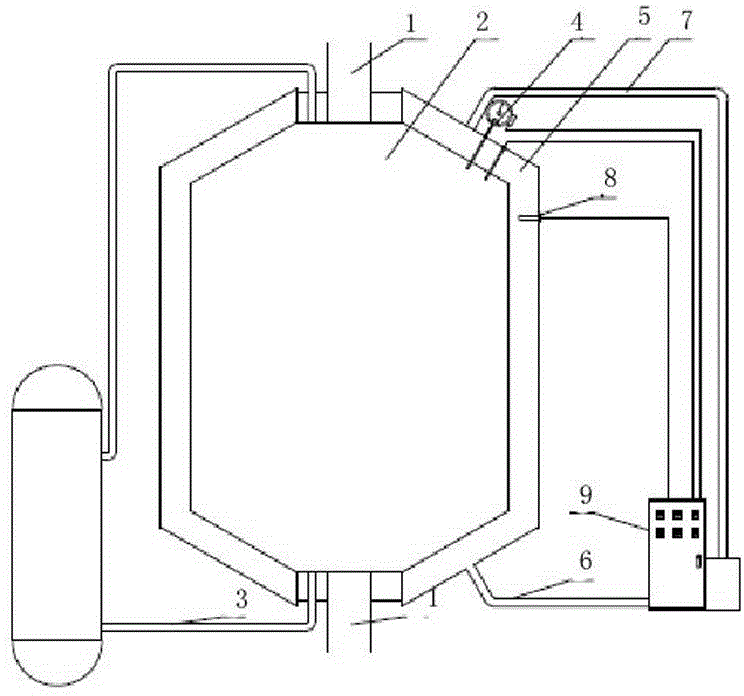

[0019] Attached below figure 1 The process flow of cross-linking agent penetration of high-pressure ultra-high-pressure cross-linked polyethylene ultra-clean insulating material produced by the present invention is described in detail.

[0020] A constant temperature and constant pressure infiltration device for ultra-clean insulating materials, which is characterized in that it includes a sealed tank, an air pump and a water tank. The tank body of the sealed tank is in the shape of a long column and conical. The upper opening and the lower opening, the sealed tank is a double-layer structure, which includes an inner layer sealed tank and an outer layer sealed tank, the inside of the inner layer sealed tank is provided with a sensor 1, and the top and bottom of the inner layer sealed tank pass through the air guide tube and the bottom respectively. The air pump is connected, the sensor II is arranged in the outer sealed tank, the lower end of the outer sealed tank is connected...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com