Bean gluten forming stick delivery table

A technology of forming sticks and bean gluten, which is applied in the direction of conveyor objects, transportation and packaging, etc., can solve the problems of low efficiency and insufficient degree of mechanization, and achieve the effect of increasing the degree of mechanization and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

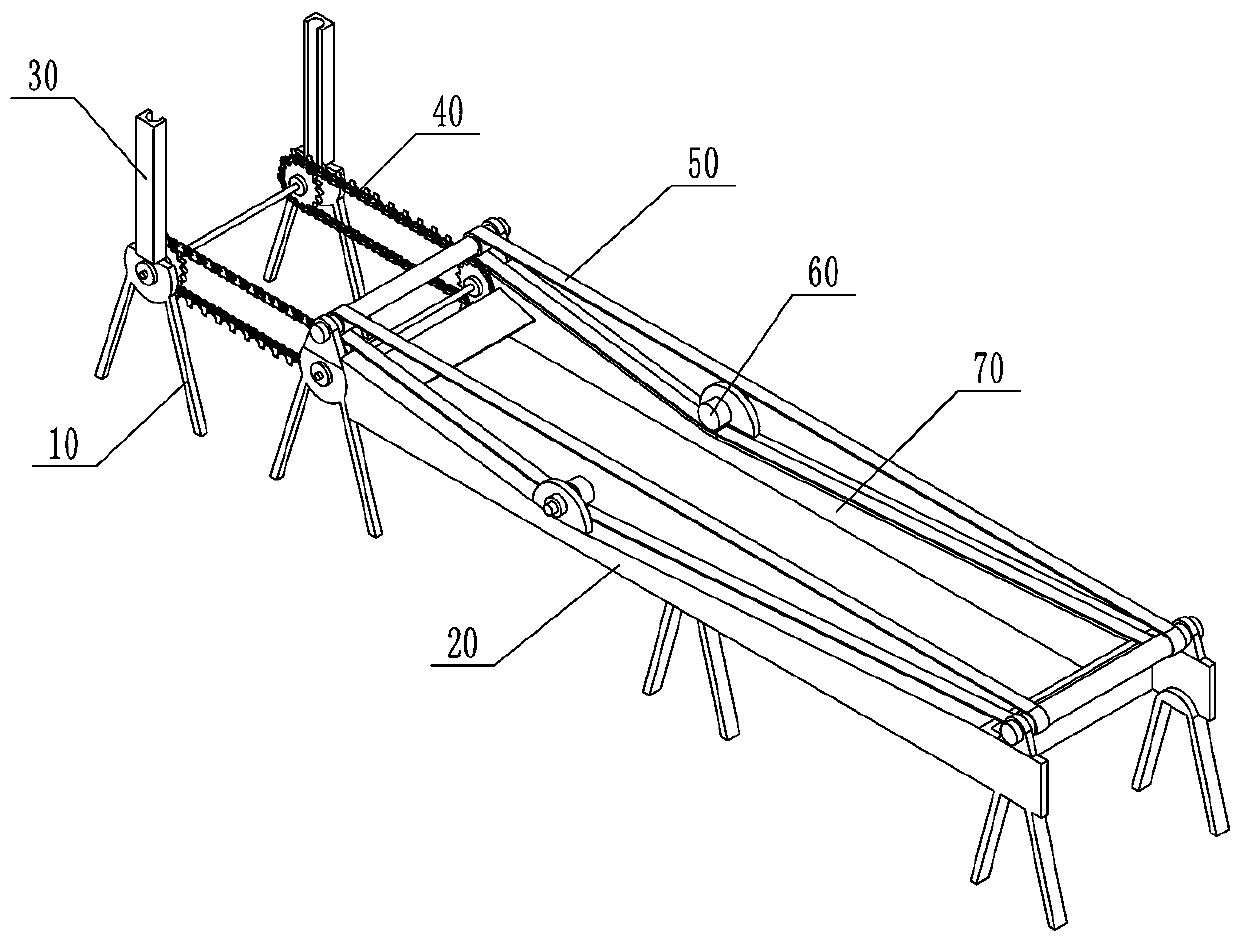

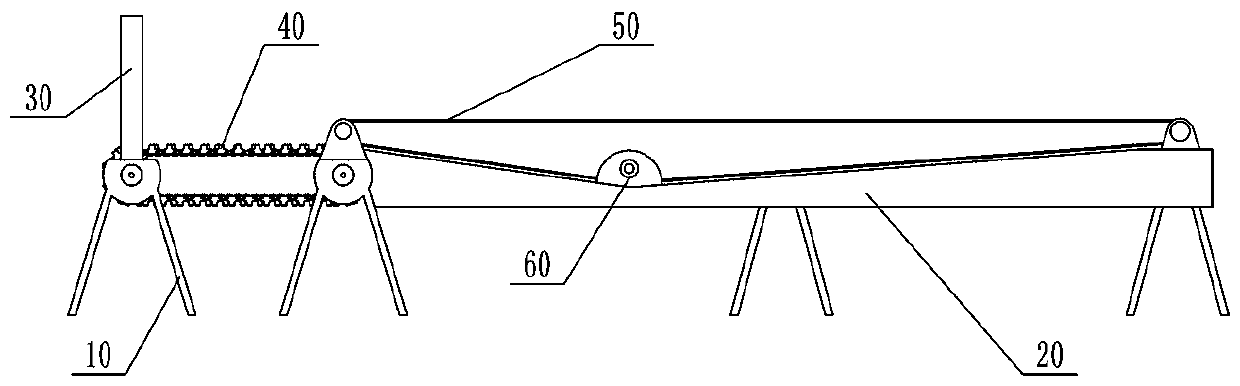

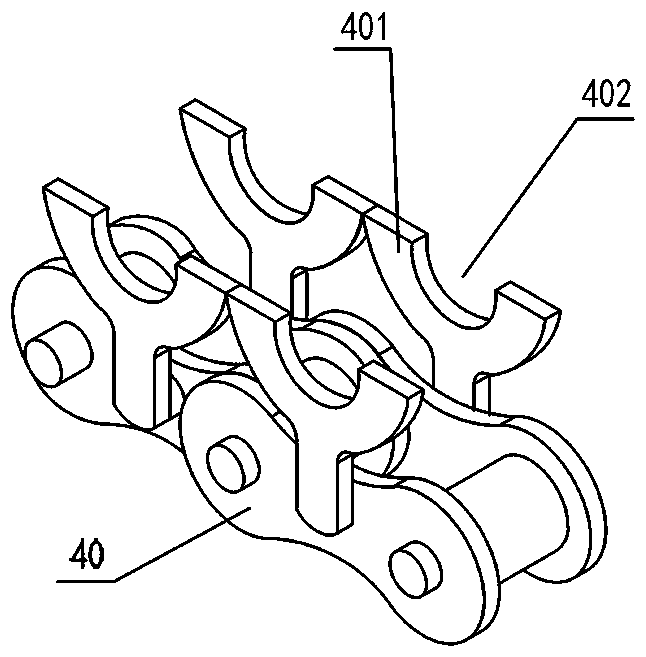

[0025] Such as figure 1 , figure 2 As shown, the present embodiment provides a bean gluten shaped stick transport platform, including a frame 10, a transport chain 40, a transmission component for driving the transport chain 40, a wrapping device and a full-row assembly. The transmission part is installed on the frame, and the transmission part mainly includes the existing common technical equipments such as driving wheel, driven wheel, connecting shaft and motor, so it is no longer stated here. The conveyor belt 50 is a toothed belt. Compared with the general conveyor belt 50, the toothed belt has a constant running speed, and it is not easy to slip when starting.

[0026] From figure 1 It can be seen that the rack 10 at the leftmost end of this embodiment is also equipped with an alignment device. The alignment device includes two alignment bars 30, and the two alignment bars 30 are equipped with a bean gluten forming bar to slide to the transport chain 40. The first gr...

Embodiment 2

[0033] Such as Figure 4 As shown, the difference between this embodiment and Embodiment 1 is that this embodiment also includes two patch rods 80 , and the second groove 801 is provided on the patch rods 80 . A connection channel 802 is processed between the second groove 801 and the first groove 301 . The connecting channel 802 is inclined downward toward the first groove 301 , and this design makes the bean gluten-shaped stick flow into the first groove 301 from the second groove 801 only in one direction. When the bean gluten-shaped sticks in the first groove 301 are insufficient, the bean gluten-shaped sticks in the second groove 801 can be supplemented. The supplementary rod 80 can be arranged side by side with the whole row of rods 30 along the direction of the transport chain 40 , thereby reducing the height occupied by the supplementary rod 80 . In addition, a plurality of supplementary rods 80 can also be provided, and the inclined connecting channels 802 can be ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com