Feeding device for rotary chute of stock bin

A technology of feeding device and chute, applied in the directions of loading/unloading, transportation and packaging, conveyor, etc., can solve problems such as unfavorable subsequent production, and achieve the effect of being beneficial to the overall structure maintenance of the silo, uniform pressure, and stable feeding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

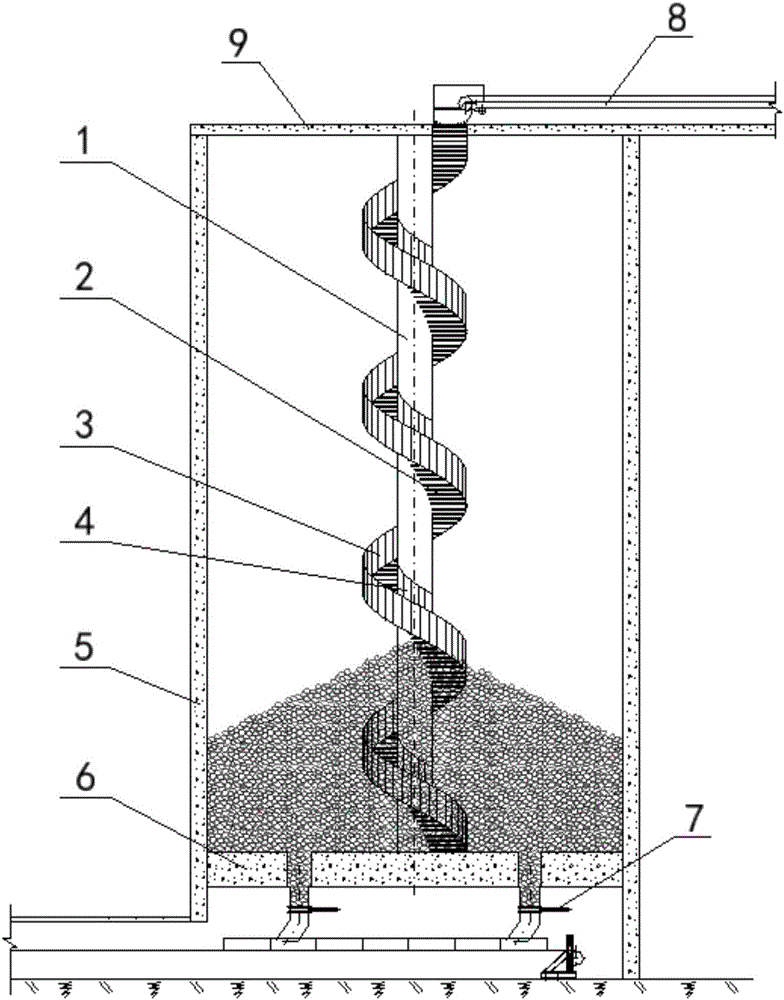

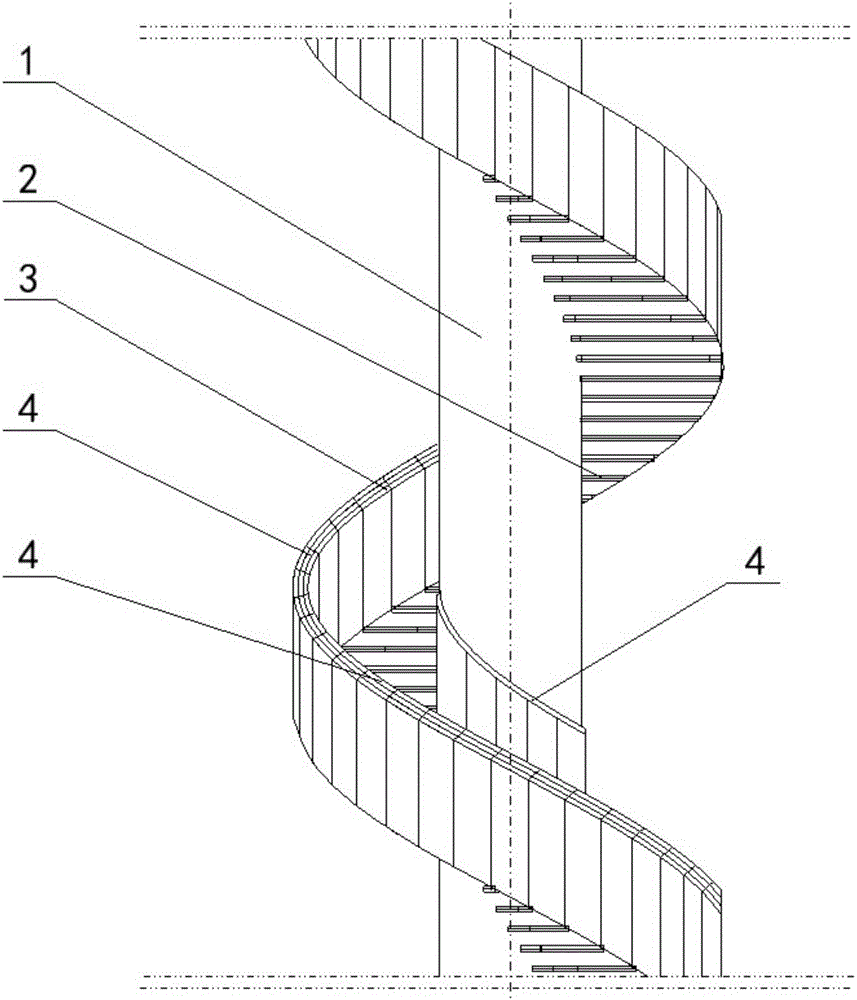

[0014] The invention comprises: a central column 1, a chute bottom plate 2, a chute side plate 3, and a wear-resistant liner 4.

[0015] Center column 1 (as attached figure 1 shown) is vertically arranged between the silo bottom plate 6 and the silo top plate 9, the chute bottom plate 2 is installed on the central column 1, the chute side plate 3 is installed on the chute bottom plate 2, and the wear-resistant liner 4 is installed on the chute side plate 3 On both sides and the central column 1.

[0016] as attached figure 1 As shown, the diameter is 20m, the height is 32m, and the volume is 10000m 3 The coke silo, the central column 1 with a diameter of 1m is vertically arranged between the silo bottom plate 6 and the silo roof 9 of the coke silo, and the chute bottom plate 2 with a width of 0.8m is installed on the central column 1 in the form of a spiral staircase. The pitch is 8m. The chute side plate 3 height 1m is vertically installed on the chute bottom plate 2, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com