Preparation and application of high-wettability epoxy resin composite material

A technology of epoxy resin and composite material, applied in the field of polymer material preparation, can solve the problem of lack of high wettability epoxy resin, etc., and achieve the effect of huge industrial production potential, low cost and low porosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] A kind of high wettability epoxy resin composite material is prepared by using epoxy resin, curing agent, defoamer and accelerator as raw materials. The epoxy resin is composed of liquid epoxy resin and solid epoxy resin. The preparation steps are as follows:

[0025] (1) Put 33kg of liquid epoxy resin bisphenol A type 128 and 67kg of solid epoxy resin bisphenol A type 901 in a 500L reaction kettle with a vacuum device, stir at 80-90℃ for 30 minutes, and mix them completely , Get mixed solution A;

[0026] (2) Add 2kg of defoamer A530 to the mixed solution A obtained in step (1), stir at 80-90°C for 30 minutes, and stir evenly to obtain a mixed solution B;

[0027] (3) Add 5 kg of curing agent 100S to the mixed solution B obtained in step (2), and stir at 70-80°C for 30 minutes to obtain a mixed solution C;

[0028] (4) Add 0.8kg of accelerator UR500 to the mixed solution B obtained in step (3), and stir at 70-80°C for 10 minutes to obtain mixed solution D, the viscosity of wh...

Embodiment 2

[0032] A kind of high wettability epoxy resin composite material is prepared by using epoxy resin, curing agent, defoamer and accelerator as raw materials. The epoxy resin is composed of liquid epoxy resin and solid epoxy resin. The preparation steps are as follows:

[0033] (1) Put 33kg of liquid epoxy resin bisphenol A type 128 and 67kg of solid epoxy resin bisphenol A type 901 in a 500L reaction kettle with a vacuum device, stir at 80-90℃ for 30 minutes, and mix them completely , Get mixed solution A;

[0034] (2) Add 2kg of defoamer A530 to the mixed solution A obtained in step (1), stir at 80-90°C for 30 minutes, and stir evenly to obtain a mixed solution B;

[0035] (3) Add 5 kg of curing agent 100S to the mixed solution B obtained in step (2), and stir at 70-80°C for 30 minutes to obtain a mixed solution C;

[0036] (4) Add 2kg of accelerator UR500 to the mixed liquid B obtained in step (3), and stir at 70-80°C for 10 minutes to obtain mixed liquid D, the viscosity of which is...

Embodiment 3

[0041] The application of the high wettability epoxy resin composite material of the above embodiment 1-2 is specifically:

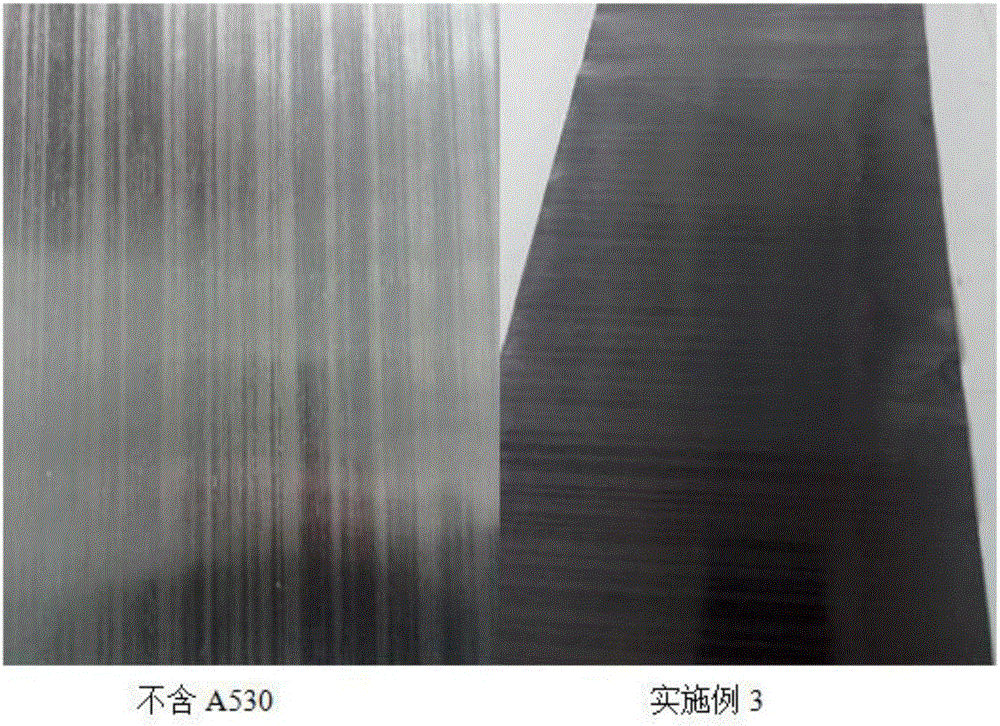

[0042] Put the mixed solution D in the glue spreader, detect the thickness of the glue film or the surface density of the glue film through an infrared meter, reduce the temperature of the glue film through the cooling plate, reduce its curing degree, and make the glue film used for the prepreg; Then the above-mentioned film is drawn from the upper and lower film rolls of the prepreg machine, and forms a sandwich structure with the carbon fiber. It passes through several sets of hot pressing rolls to melt the resin matrix, and the carbon fiber is embedded in the resin matrix to cool down the prepreg. Temperature, trimming, PE film, and rewinding are performed to obtain a resin content of 25% high wettability epoxy resin carbon fiber prepreg, and the same resin content as the one prepared without defoaming agent A530 % Epoxy resin carbon fiber prepreg for co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| bending strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| bending strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com