Three-dimensional control masonry method based on oven body masonry construction of coke oven

A technology of three-dimensional control and coke oven, which is applied in coke oven bricklaying operations, etc., can solve the problems of low construction efficiency, poor quality of masonry, and high cost, and achieve the effect of improving construction efficiency, improving masonry quality, and large adjustment space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

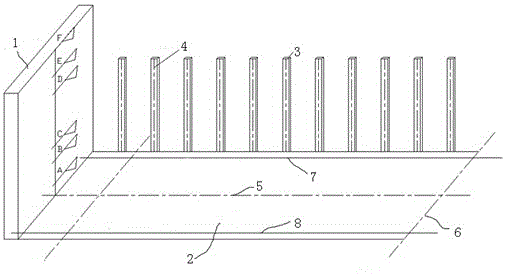

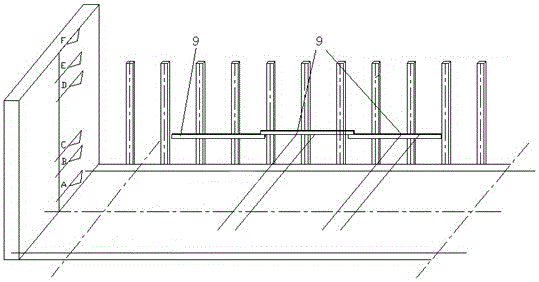

[0021] This embodiment provides a three-dimensional control masonry method based on coke oven body masonry construction. Using this method, the construction technology of first erecting the furnace column (vertical, elevation control) in the prior art can be improved, and the subsequent electromechanical The construction of the installation project brings a large adjustment space, which is conducive to the orderly progress of the construction rhythm of the overall coke oven project.

[0022] This method includes three aspects: the control of height dimension, the control of longitudinal dimension and the control of transverse dimension. Through these three aspects (three-dimensional) to realize the dimension control when building the coke oven, so that the cold state dimension of the coke oven can be obtained. effective control.

[0023] The three-dimensional control masonry method based on the coke oven body masonry construction mainly includes the following contents:

[002...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com