Constant temperature water bath apparatus for chemical plating

A technology of constant temperature water bath and electroless plating, which is applied in the field of solar cells, can solve problems such as unsatisfactory requirements, and achieve the effects of ensuring chemical stability, ensuring flatness, and good heat preservation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

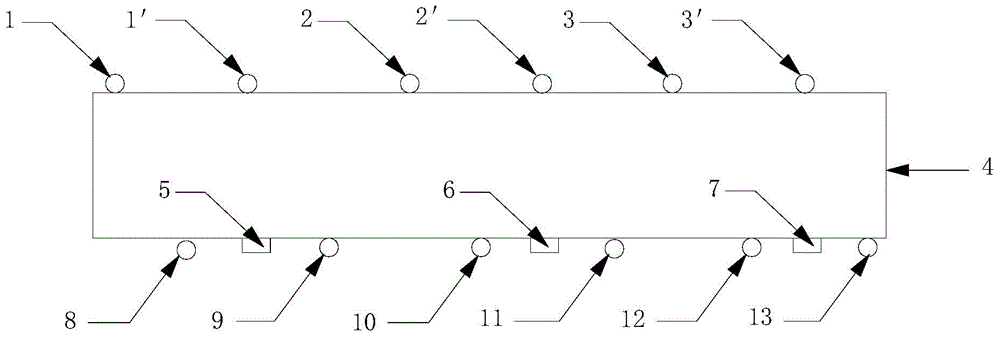

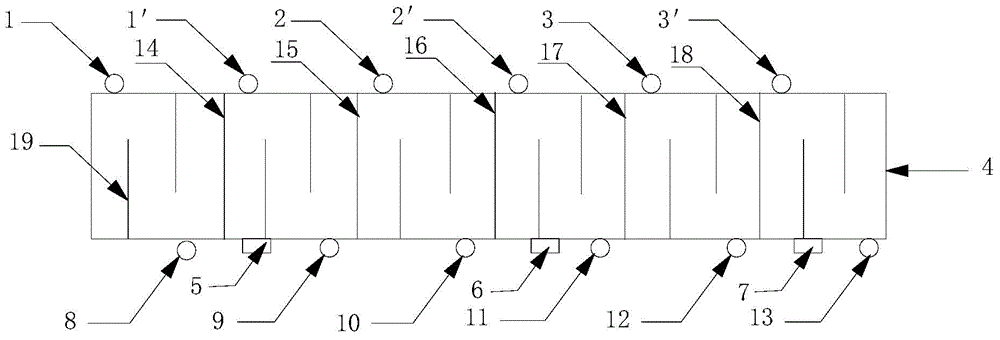

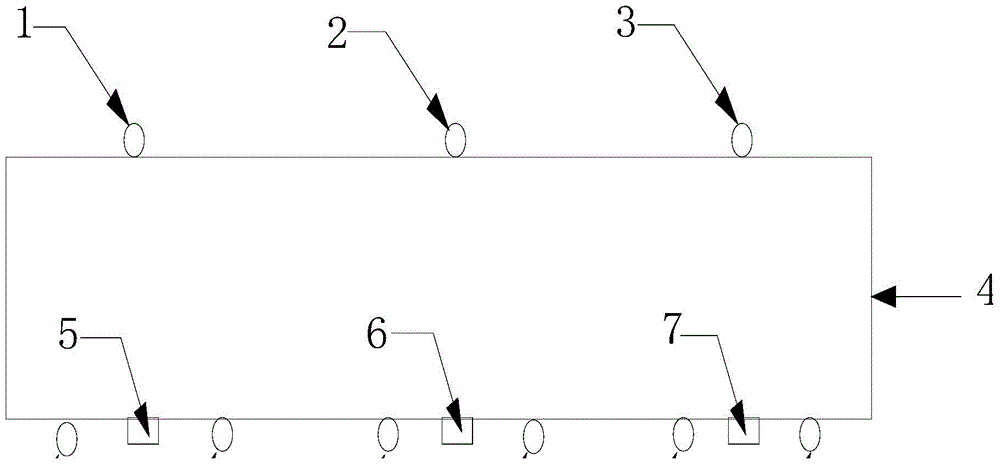

[0027] A constant temperature water bath device for electroless plating. The outer pipeline is heated by the multi-input and multi-outlet circulation pipeline water filling method. The whole tank is divided into multiple circulation chambers, and each circulation chamber is single-in and single-out. The circulation chamber is equipped with a serpentine baffle, the material of the circulation chamber panel and the partition is brass, and the surface of the panel is sprayed with a layer of polytetrafluoroethylene film. The circulation cavity is equipped with a temperature sensor.

[0028] The panel and the partition are welded by brass, and then connected with the stainless steel bottom plate by screws; the whole tank is divided into 6 circulation cavities.

[0029] Concrete structure and implementation process of this embodiment:

[0030] At present, the external dimensions of the tank body of the known electroless plating constant temperature water bath device are 2000mm×370m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com