Long-service-life drill bit with self-repairing capacity

A long-life, self-repairing technology, used in drill bits, drilling equipment, earth-moving drilling, etc., can solve the problems of low feeding capacity, low rock breaking efficiency, and reduced cutting gear ratio pressure value, and achieve the effect of improving efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

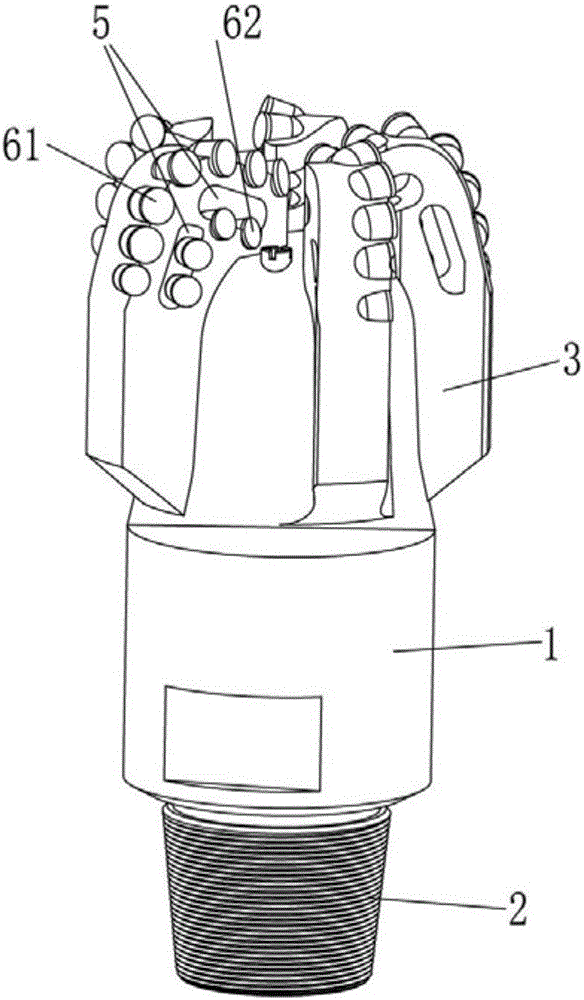

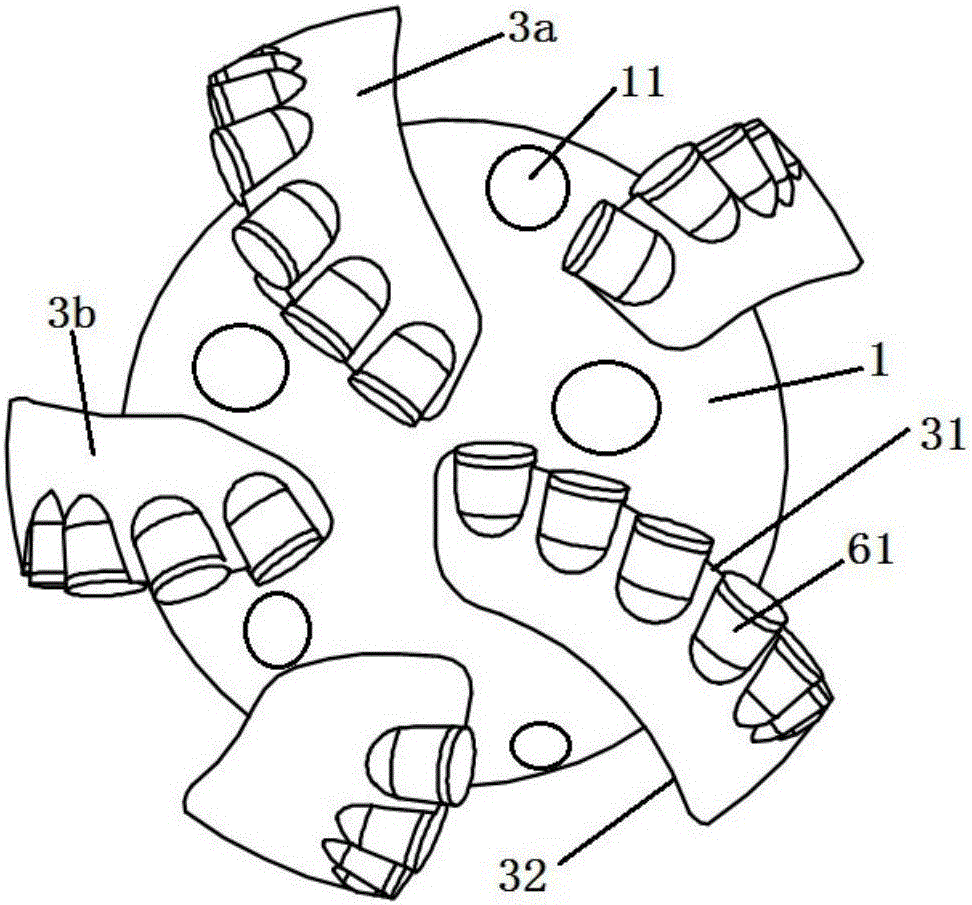

[0083] Such as Figure 1-6 , 8, a long-life PDC drill bit includes a drill bit body 1, a connecting thread 2, several water holes 11 and several blades 3 arranged on the drill bit body 1. Wherein said blade 3 can be such as figure 2 , 18 , the main blade 3a shown in 19 can also be as figure 2 , 20 , The auxiliary blade 3b shown in 21,22. The main difference between the main blade 3a and the auxiliary blade 3b is that the length of the blade 3 extends to the core area of the drill bit, which is the main blade 3a, and the length not extending to the core area of the drill bit is the auxiliary blade 3b.

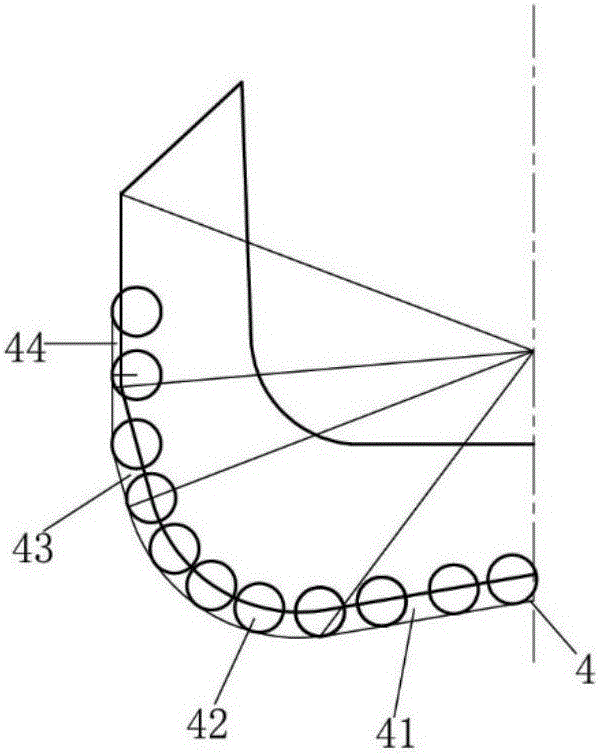

[0084] In this example, if image 3 As shown, each blade includes a blade tooth surface composed of blade inner cone region 41 , crown region 42 , shoulder region 43 , blade front side 31 and blade rear side 32 . Wherein, dimples are arranged on the cloth tooth surface of each blade 3, and the first group of cutting teeth 61 are fixed in the dimples; There is at lea...

Embodiment 2

[0098] Such as Figure 9 As shown, this embodiment is basically the same as Embodiment 1. The difference is that: the blade 3 is provided with an empty slot 5 , and more than one second group of cutting teeth are fixed in the empty slot 5 . When there is only a single continuous empty groove 5 on a certain blade 3, it is beneficial to apply this tooth arrangement form. In this embodiment, by fixing a plurality of cutting teeth of the second group in one hollow slot, the tooth density of the cutting teeth of the second group can be further increased, and the service life of the PDC bit can be improved.

Embodiment 3

[0100] Such as Figure 10 As shown, this embodiment is basically the same as Embodiment 1. The difference is that two or more hollow grooves 5 are provided on the blade 3, at least two hollow grooves 5 are arranged in different radial areas of the drill bit, and at least one second hollow groove 5 is provided in each hollow groove 5. Set of cutting teeth 62 . By arranging two or more discontinuous hollow groove structures on the blade body, it is possible to avoid excessive reduction in the structural strength of the blade due to too large or too long hollow grooves on the blade, which may cause the blade to collapse. danger of breaking.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com