Continuously moving oil rig as well as pull-out and run-in methods thereof

A motion and oil technology, applied in the fields of continuous motion tripping, continuous motion oil drilling rig, and continuous motion drilling down, can solve the loss of circulation, well collapse, impact on the stability of the wellbore wall, and impact on the bottom hole in the fractured formation. Drilling rig work efficiency and other issues, to achieve the effect of less impact of bottom hole pressure fluctuations, improved wellbore stability, and increased tripping speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

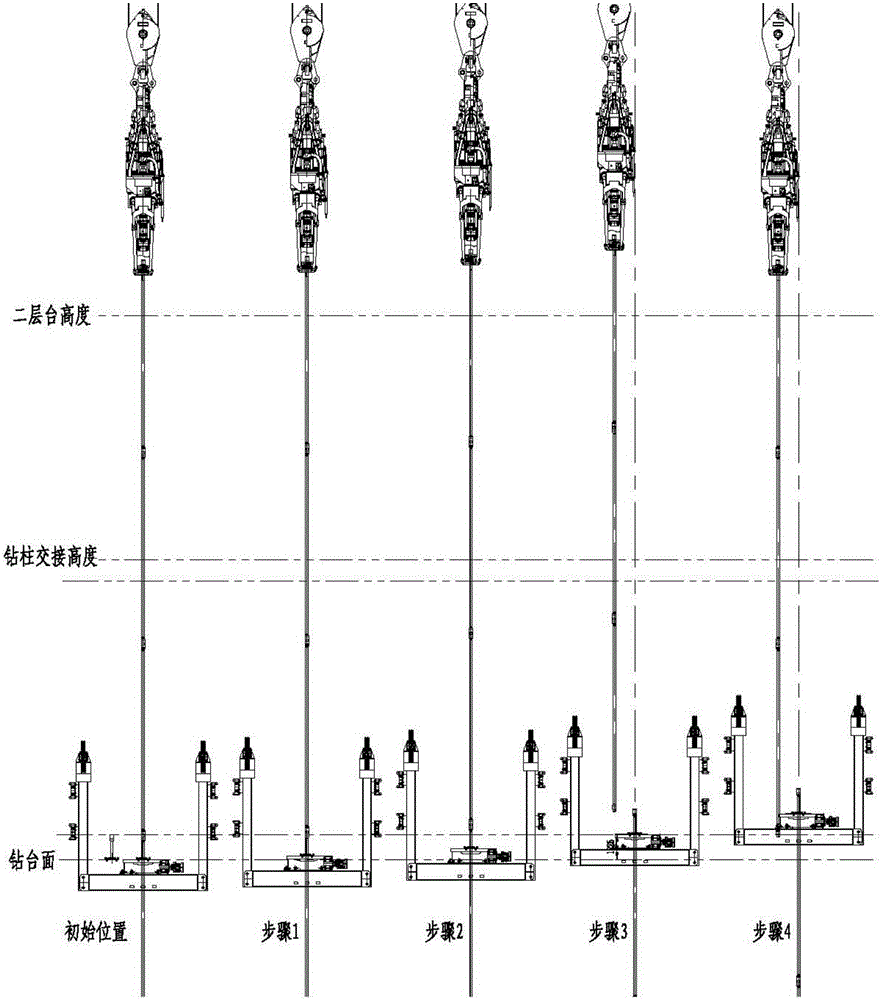

[0044] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0045] The turntable and turntable beam of conventional oil drilling rigs are installed on the base and cannot move up and down along the center line of the vertical wellhead. The present invention is designed to increase a set of rotating disk lifting mechanism for rotating disk 4 on the basis of conventional oil drilling rigs.

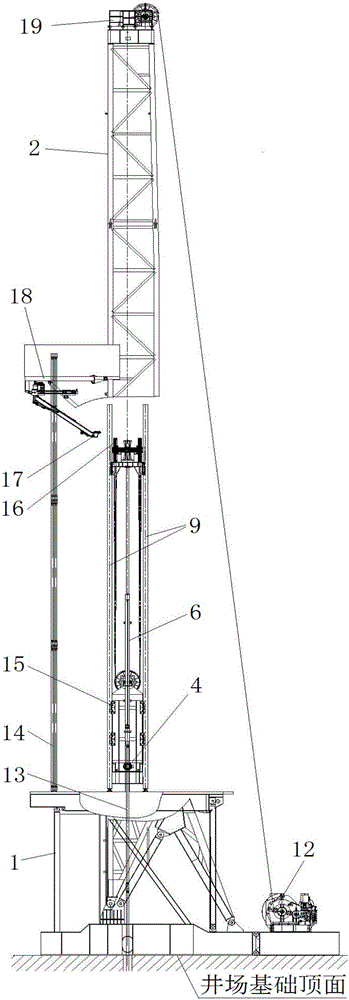

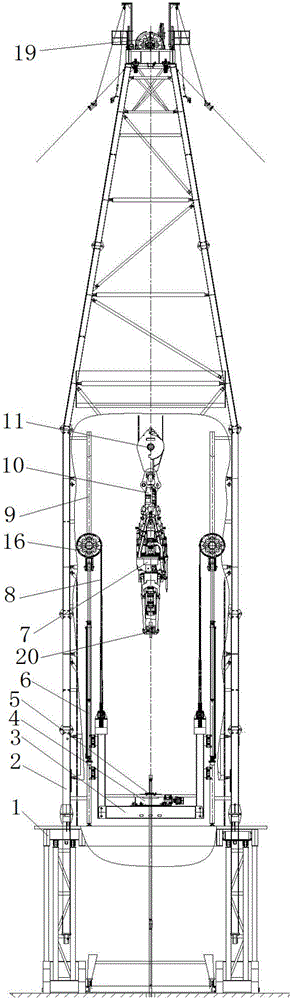

[0046] refer to figure 1 , figure 2 , the structure of the continuous motion oil drilling rig of the present invention is that the derrick 2 is installed on the base 1 of the rig, and two sets of hoisting mechanisms are arranged in the derrick 2, one set is the top drive hoisting mechanism for the top drive 7, and the other is for the top drive 7. The turntable lifting mechanism of turntable 4,

[0047] The top drive hoisting mechanism is the same in structure as the top drive hoisting mechanism of conventional ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com