Electricity generating and drying integrated system and working method

A working method and drying technology, which is applied in the direction of drying solid materials, drying gas arrangement, and preliminary treatment to promote the drying of solid materials, and can solve the problems of reducing air temperature, cooling medium, and consuming large energy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

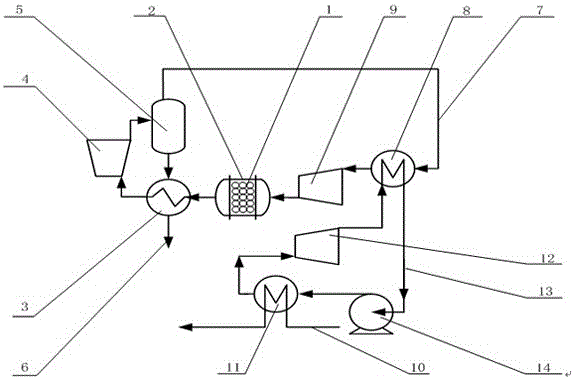

[0018] Refer to the attached figure 1 Describe the operation process of the power generation and drying integrated system and working method:

[0019] The working medium 13 enters the cold side of the evaporator 11 after being pressurized by the working medium pump 14, absorbs the heat of the heat source 10 until it is completely evaporated, enters the second expander 12 to expand and perform work, and then enters the hot side of the condenser 8, and the heat on the cold side of the condenser 8 The drying medium 7 is heated, and after cooling, it is pressurized by the working medium pump 14 to complete the steam Rankine subcycle; the heat source 10 enters the hot side of the evaporator 11, heats the working medium 13 on the cold side of the evaporator 11, and then discharges from the outlet of the hot side of the evaporator;

[0020] The drying medium 7 enters the cold side of the condenser 8, absorbs the heat of the hot side of the condenser 8, further increases the temperatu...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap