Intermediate coupling system for generator and gearbox

A generator and gearbox technology, which is applied in the field of mechanical coupling devices and two-shaft coupling devices, can solve the problems of insufficient elimination of gravity G component, low reliability, and coupling distortion, and reduce the maximum dynamic load. impact, increase operating life, and reduce weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The technical solution of the present invention is described in detail below in conjunction with the accompanying drawings of the description:

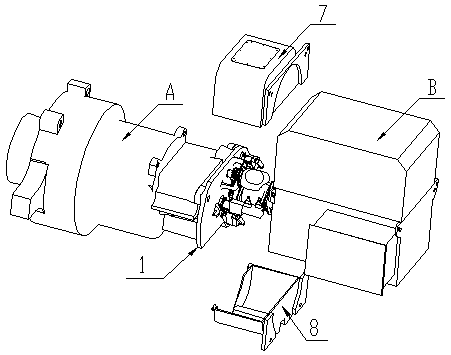

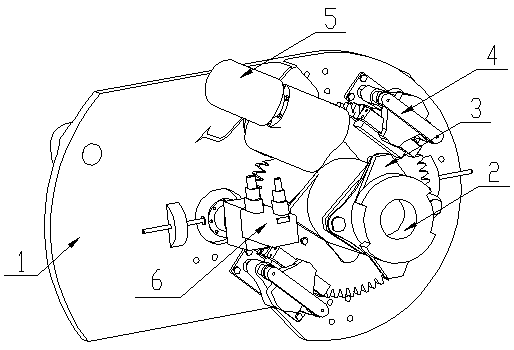

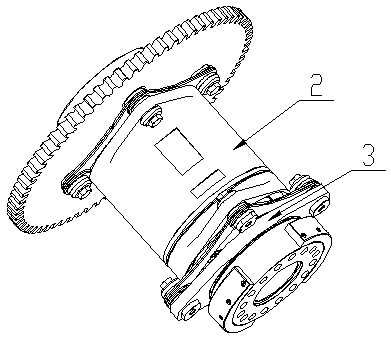

[0027] Such as figure 1 , figure 2 As shown, an intermediate coupling system for a generator and a gearbox is characterized in that it includes a base 1, a coupling 2, a shackle device 3, a brake 4, a crank 5, a power transmitter 6, and an upper cover 7 , The lower cover 8 is installed on the plane base between the generator A and the gear box B, and forms a frame structure in the axial direction of the generator A, and uses a ball joint to connect the generator A and the gear box B to form a double Connecting rod mechanism; on the coupling 2, the visual elongation glass fiber tube and the torsion sensor are firmly pasted, and the elongation or twisting of the glass fiber tube takes place, and the visual elongation of the glass fiber tube and the torsion sensor It is visually displayed on the upper cover 7, and a visual mova...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com