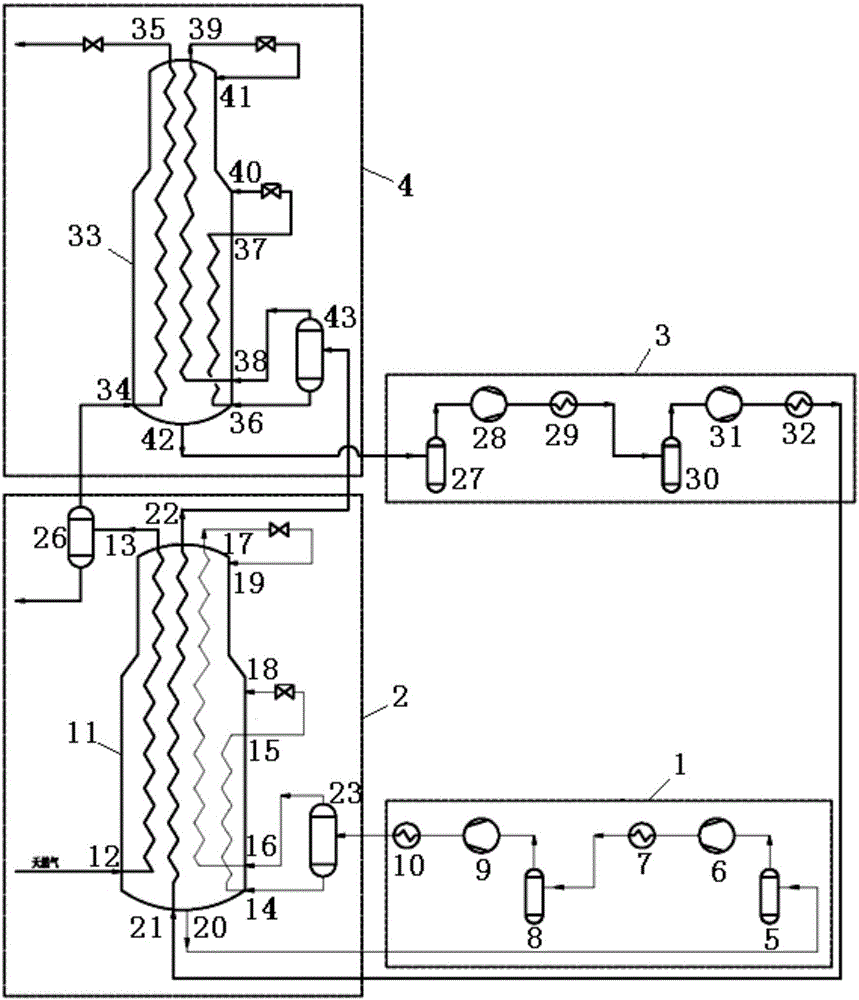

Double-refrigerant circulating natural gas liquefaction system based on wound-tube heat exchanger

A coiled-tube, natural gas technology, applied in refrigeration and liquefaction, liquefaction, climate sustainability, etc., can solve problems such as inability to meet offshore production conditions, complex system processes, and large equipment size, reducing engineering costs. The effect of construction difficulty and project investment cost, streamlined system process and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0034] The liquefaction system provided by the present invention is used to develop and utilize an offshore gas field. Firstly, the purified raw natural gas (at a temperature of 45.0°C and a pressure of 4.0MPaA) is introduced into the main low-temperature heat exchanger 11 for pre-cooling, and the pre-cooled mixed refrigerant Cool to -50°C, enter the gas-liquid separator 26 for gas-liquid separation, the separated condensate is connected to the outside from the bottom of the separator, and the gas-phase natural gas obtained after separation enters the main low-temperature heat exchanger 33 for low-temperature liquefaction, and is cryogenically mixed The refrigerant is cooled to -153°C, throttled through the throttle valve, and the pressure is reduced to 0.2MPaA, and the produced LNG is led out to external storage.

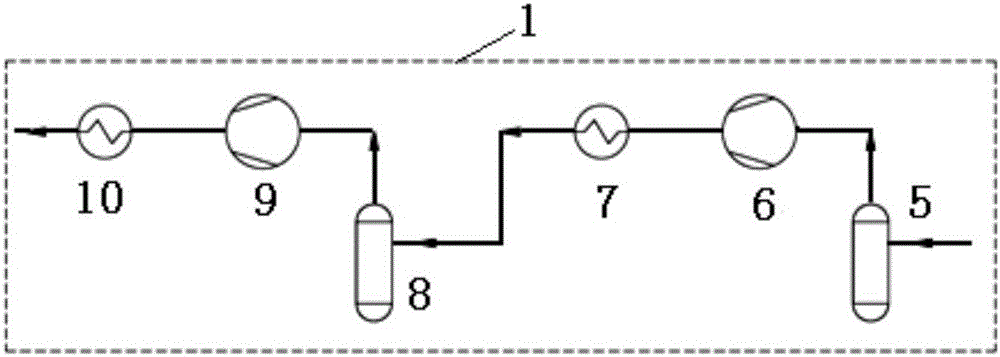

[0035] The low-pressure precooling mixed refrigerant (temperature 19.0°C, pressure 0.21MPaA) from the main low-temperature heat exchanger 11 is sequentially compres...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com