A sensor noise signal suppression method in the process of three-point rotation error separation

A sensor noise and separation process technology, applied in the direction of instruments, measuring devices, etc., can solve the problems of affecting the separation results of errors and the amplification of negative effects of noise interference signals, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

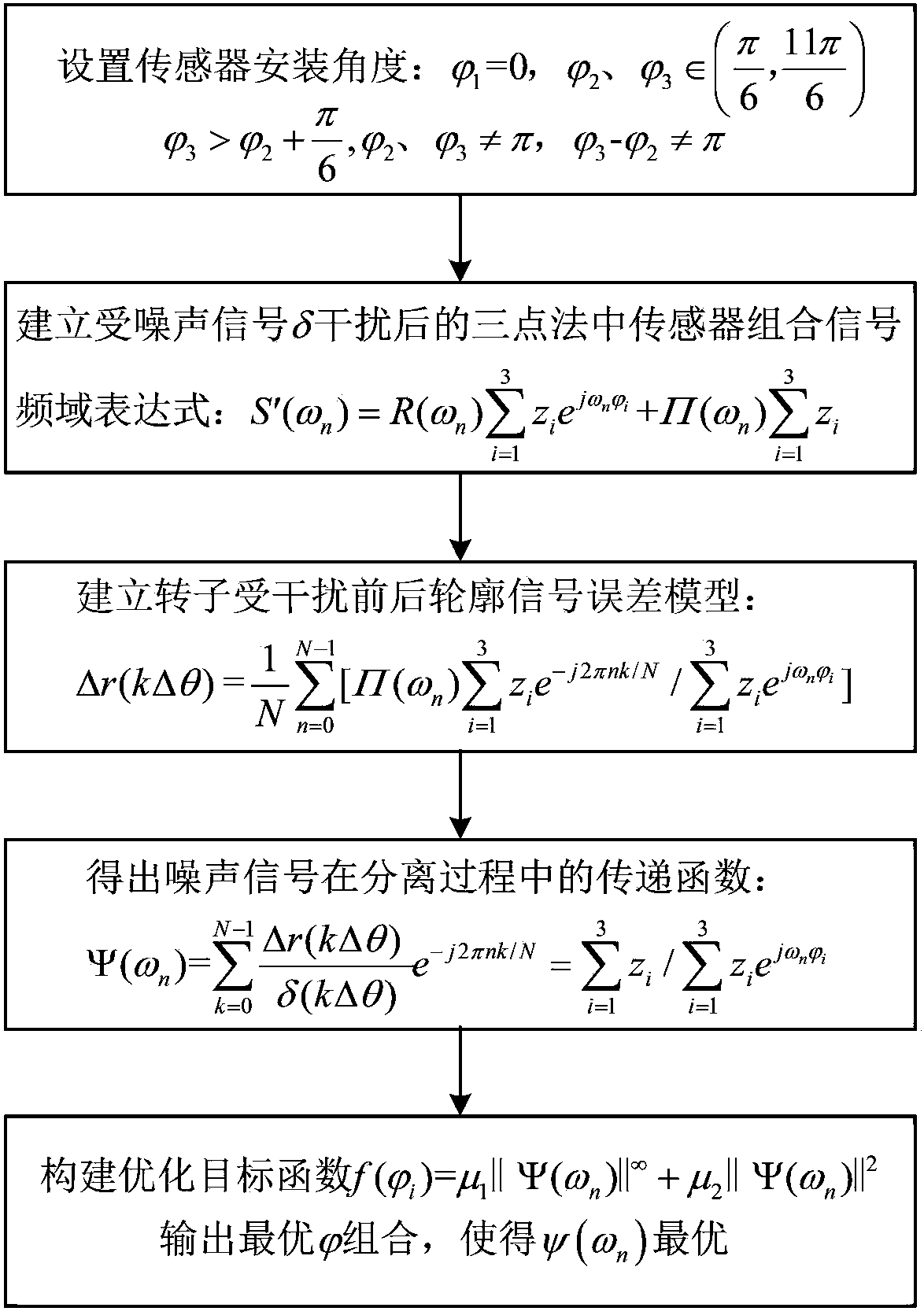

[0052] The process of the present invention is as figure 1 As shown, below in conjunction with accompanying drawing the embodiment of the present invention is described in detail:

[0053] 1. Optimize the construction of the objective function

[0054] Arrange i probes S along the test reference circle i (i=1,2,3), the angles between each sensor head and the x-axis are respectively Establish the frequency domain expression of the combined sensor signal in the three-point method after being affected by the noise signal δ interference:

[0055]

[0056] Among them, n is the serial number of discrete values in the frequency domain, and n=0,1,2,...,N-1; N is the number of sampling points; R(ω n ) is the frequency domain expression of the test section profile signal r(kΔθ), ∏(ω n ) is the frequency-domain expression of the noise signal δ.

[0057] The error between the separated rotor profile signal r′(kΔθ) and the rotor true profile signal r(kΔθ) after being affecte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com