A high-stiffness embedded device for multi-body separation test in hypersonic wind tunnel

An embedded device and multi-body separation technology, which is applied in the direction of measuring device, aerodynamic test, machine/structural component test, etc., can solve the problems of high motion precision, difficult high rigidity, six degrees of freedom are not completely independent, etc. problem, to achieve the effect of space reuse, increase stiffness and bearing capacity, and reduce wind tunnel blockage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

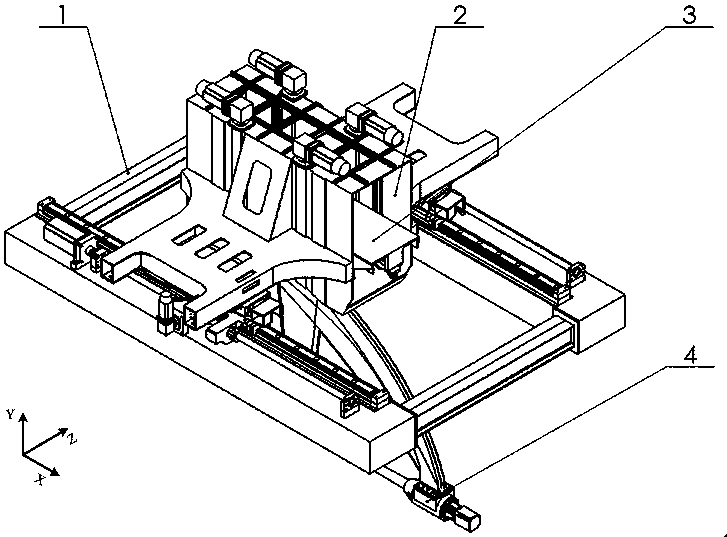

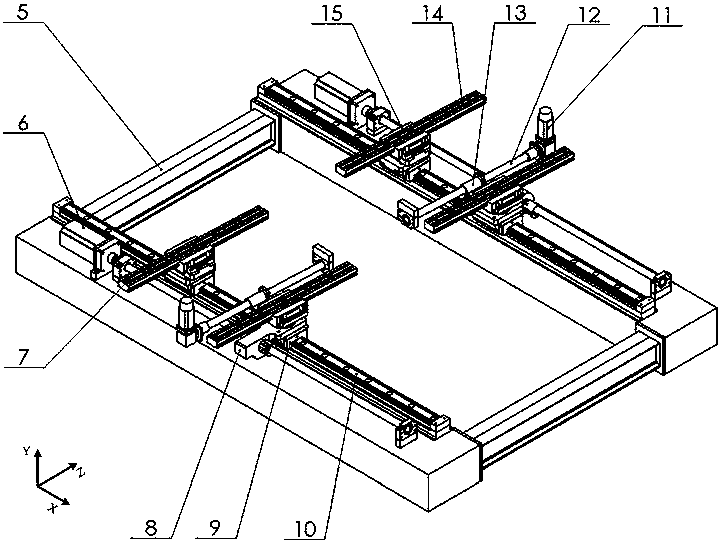

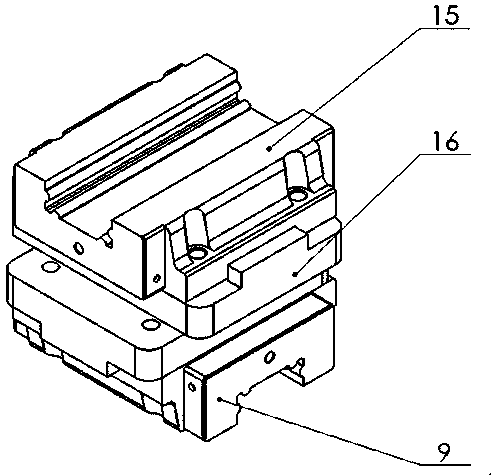

[0032] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

[0033] Such as Figure 1-7 As shown, the structure of the high-rigidity embedded device adopts a parallel-series hybrid connection, in which X-direction movement, Z-direction movement and β The movement is realized by a three-degree-of-freedom parallel platform 1, Y-direction movement, α sports and gamma The movements are realized by independent mechanisms; the three-degree-of-freedom parallel platform 1 and the three independent mechanisms are connected in series through embedded integration, and a high-rigidity embedded device for multi-body separation tests in a hypersonic wind tunnel can be obtained.

[0034] The first layer is a three-degree-of-freedom parallel platform 1, which realizes X-direction, Z-direction and β Attitude adjustment in three degrees of freedom. The Y-direction mechanism 2 is connected to the parallel motion platform 17 of the th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com