Carbide round bar drop strength tester

A cemented carbide and strength detection technology, applied in the direction of strength characteristics, instruments, measuring devices, etc., can solve the problems that the cemented carbide round bars cannot be guaranteed to fall uniformly, the false detection rate is high, and achieve reliable measurement results and landing force. Uniform, compact effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] A device for semi-automatic detection of the landing strength of a cemented carbide round rod is designed. The device automatically feeds the material and controls the force of the round rod to be even when it falls to the ground.

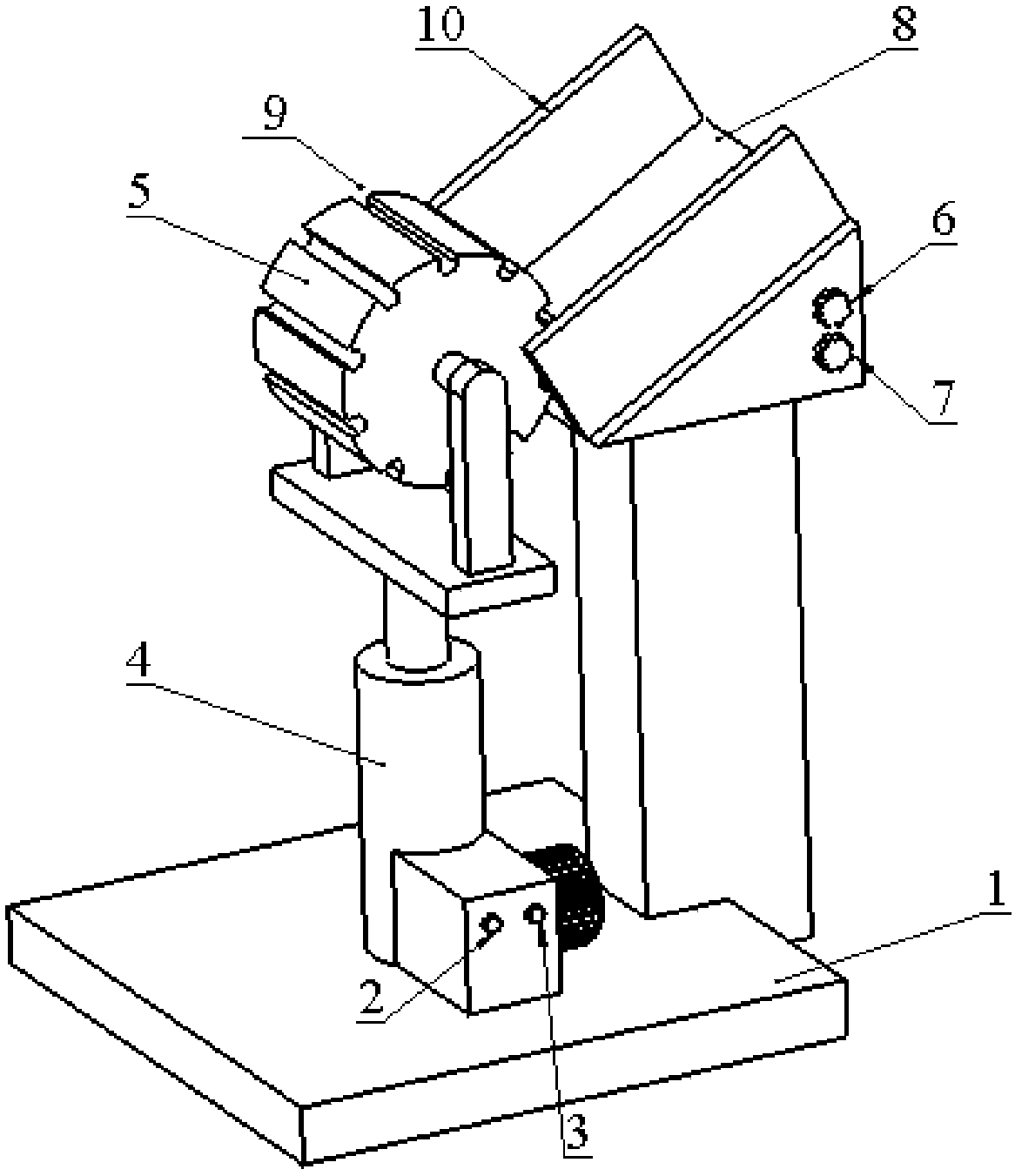

[0023] Such as figure 1 As shown, the cemented carbide round rod landing strength tester includes a horizontal base 1, a lifting device 4 and a runner 5, a lifting device 4 is vertically installed on the horizontal base 1, a supporting seat is provided on the lifting device 4, and the rotating wheel 5 rotates Freely supported on the support seat, the outer edge of the runner 5 is evenly and symmetrically opened with a plurality of axial U-shaped grooves 9 along the circumference, the runner 5 is driven and connected by a motor, and the motor is connected to a controller for controlling its speed Control connection; a column is installed next to the lifting device 4, an inclined plane lifting device is installed on the column, an inclined pla...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com