High-frequency resistance straight seam welding quality state online detection method

A technology of straight seam welding and high-frequency resistance, applied in image data processing, instruments, biological neural network models, etc., can solve problems such as unsatisfactory recognition rate, complex image processing algorithm, and affecting real-time detection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

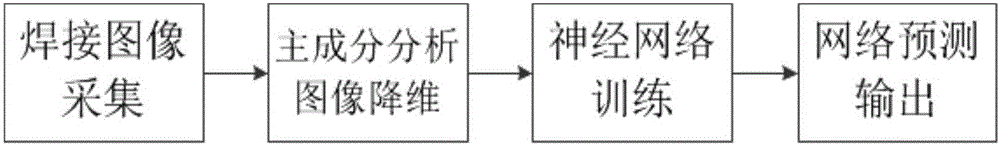

[0029] see figure 1 The online detection method of the high-frequency resistance straight seam welding quality state of the present invention mainly comprises the following steps: welding image acquisition, principal component analysis (Principal Component Analysis, PCA) image dimensionality reduction, radial basis neural network (RadialBasisFunctionNeuralNetwork, RBFNN) training and Network prediction output, this method can effectively complete the online detection of welding quality status.

[0030] (1) Welding image acquisition

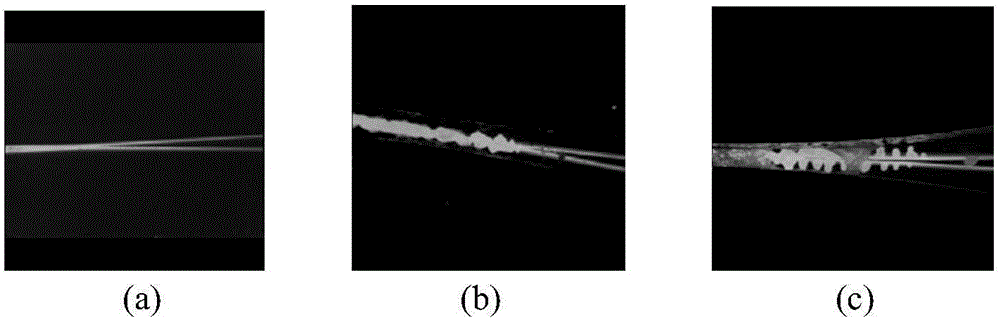

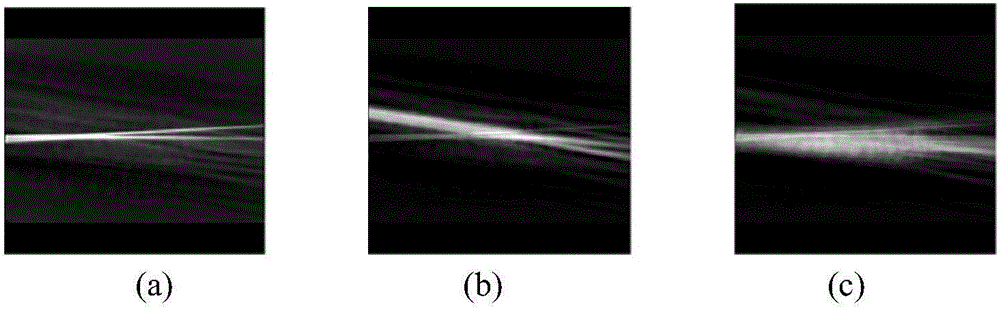

[0031] The welding image of the present invention is the image of the welding fusion phenomenon collected by a high-speed CCD camera. The size of the welding image is 320×320. As the image size increases, the time-consuming prediction will increase. In order to train the radial basis neural network, through Set three di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com