Tubular coil coupler structure

A coupler and tube-type technology, applied in the field of tube-type coil coupler structure, can solve the problems of low coupling efficiency and poor heat dissipation, and achieve the effects of reasonable distribution of magnetic force lines, fast heat dissipation, and low coupling frequency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

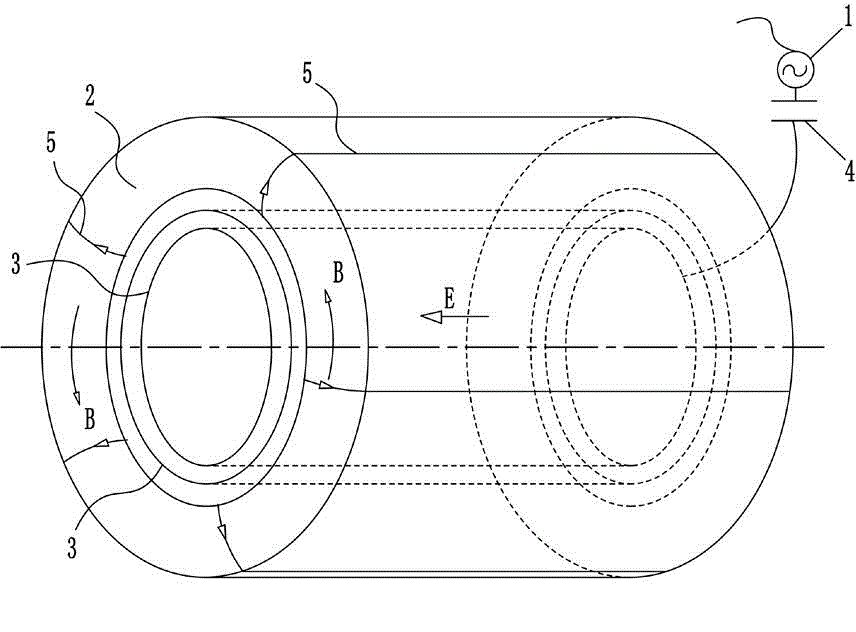

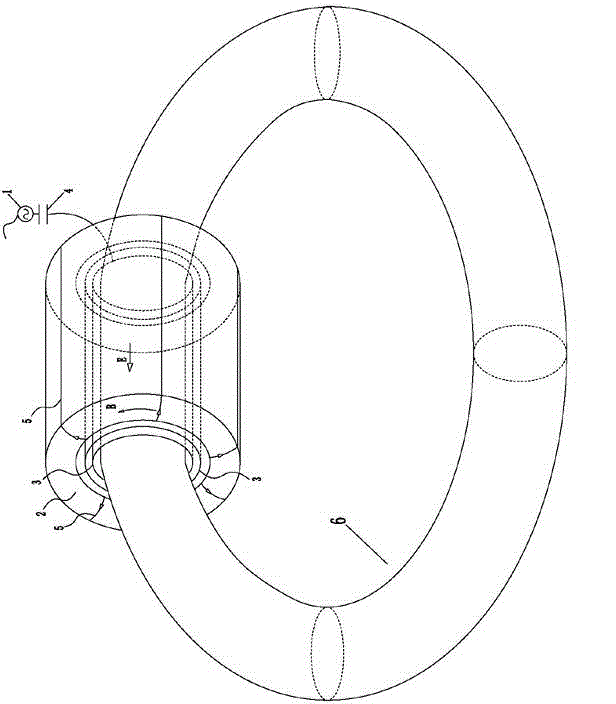

[0030] Such as figure 1 and figure 2 Shown is a schematic diagram of an embodiment of an external tubular coil coupler provided by the present invention, which includes an alternating power source 1, a hollow annular ferromagnetic core 2, a tubular metal ring group, several capacitive elements 4, a screw Winding coil 5; the hollow annular ferromagnetic core 2 is sheathed on the outer periphery of the tubular eyelet group. Such as figure 1 As shown, the spirally wound coil 5 is a coil structure in which a spirally wound wire is repeatedly wound inside and outside the side wall of the hollow annular ferromagnetic core 2, as shown in Figure 4 As shown, if the entire helical coil 5 can surround the entire hollow annular ferromagnetic core 2 to form a densely wound helical coil, the electromagnetic field will be more uniform, so that electrons can be evenly accelerated.

[0031] Such as figure 1 and 3 As shown, the tubular eyelet set includes more than one tubular eyelet A3;...

Embodiment 2

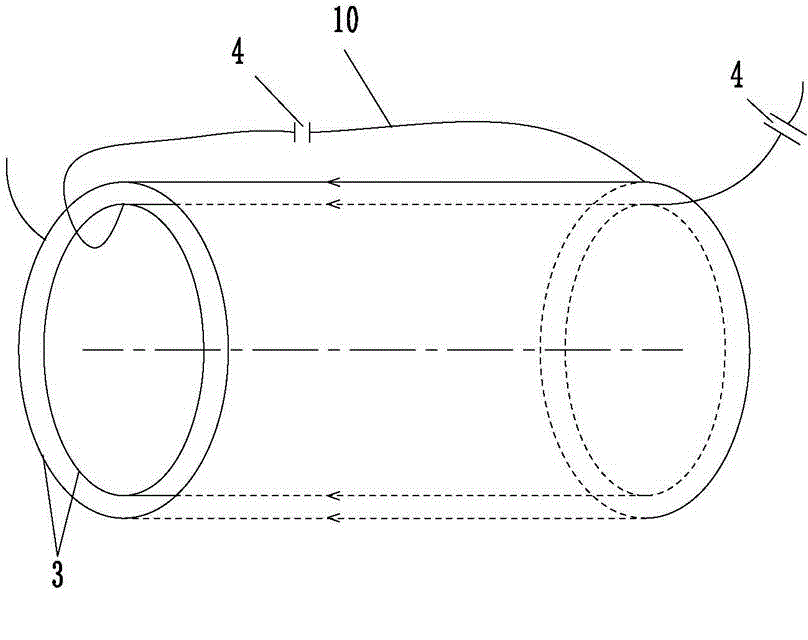

[0040] Such as Figure 10 Shown is a schematic diagram of an embodiment of a built-in tubular coil coupler provided by the present invention, which includes an alternating power source 1, a hollow annular ferromagnetic core 2, a tubular metal ring group, several capacitors 4, a screw Wound coil 5; the tubular metal ring set is sleeved on the outer periphery of the hollow annular ferromagnetic core 2, and the spiral wound coil 5 is a spiral wound wire repeatedly wound along the outer wall surface of the hollow annular ferromagnetic core 2 A plurality of wire loops are formed, and the plurality of wire loops are uniformly distributed from one end to the other end of the hollow annular ferromagnetic core 2 in sequence. Preferably, a plurality of wire loops are gradually arranged from one end of the hollow annular ferromagnetic core to the other end to form a densely wound spiral coil structure, which can ensure that the electromagnetic field around the hollow annular ferromagneti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com