Light waveguide wafer surface detecting device

A surface inspection and optical waveguide technology, used in semiconductor/solid-state device testing/measurement, semiconductor/solid-state device manufacturing, electrical components, etc., can solve the problem of lack of residual stress and grooves on the wafer surface, and facilitate comprehensive scanning inspection. , The effect of convenient and fast operation, high detection efficiency and high precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

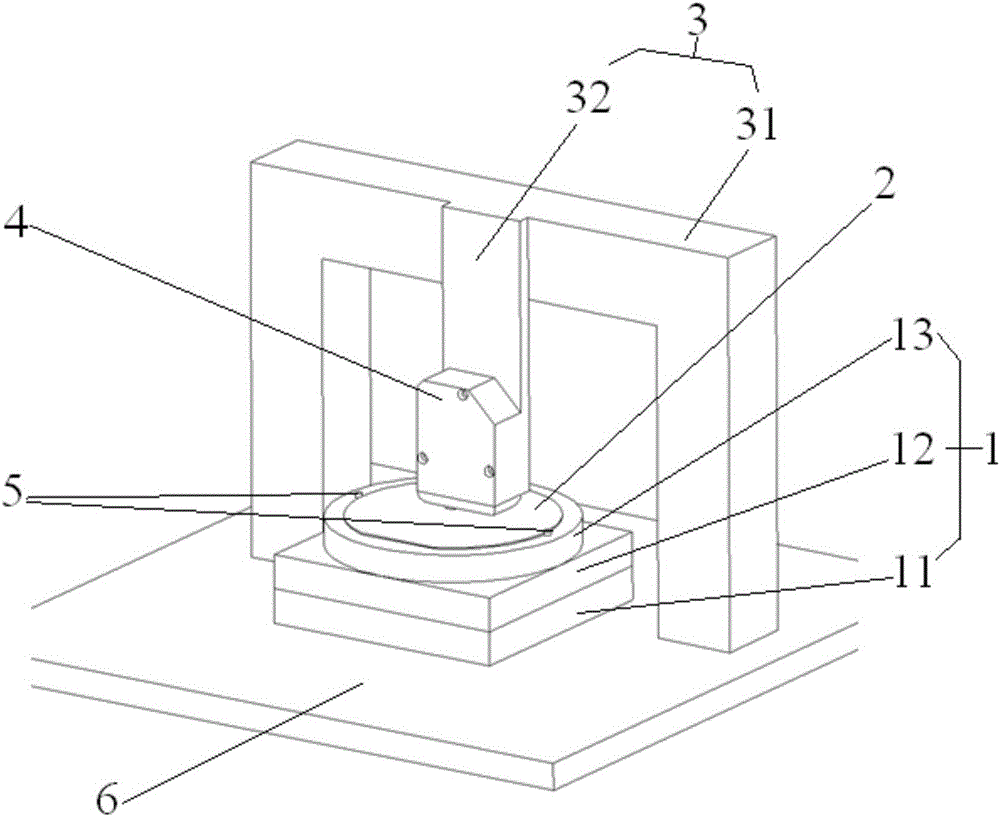

[0029] Such as figure 1 As shown, the present invention provides an optical waveguide wafer surface detection device, including a multi-directional motion platform 1 capable of moving in multiple directions along a horizontal plane, a laser confocal scanning probe 4 and a fixed bracket 3, the laser confocal scanning probe 4 is set on the fixed bracket 3, the wafer to be inspected 2 is placed on the multi-directional motion platform 1, and the laser confocal scanning probe 4 is located above the wafer to be inspected 2, the multi-directional The motion platform 1 drives the wafer to be inspected 2 to move in multiple directions, so that the laser confocal scanning probe 4 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com