Thermographic inspection system

A detection system, thermal imaging technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The following description is merely exemplary in nature, and is not intended to limit the present invention, application, or use.

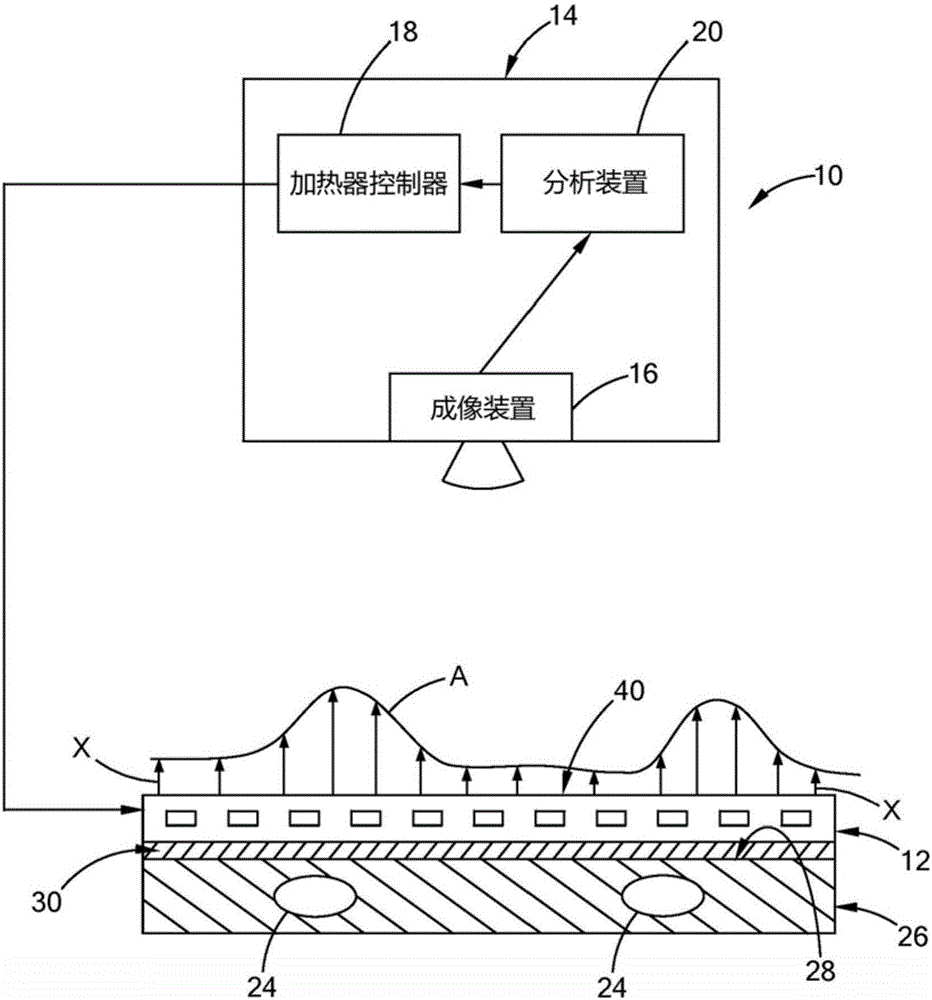

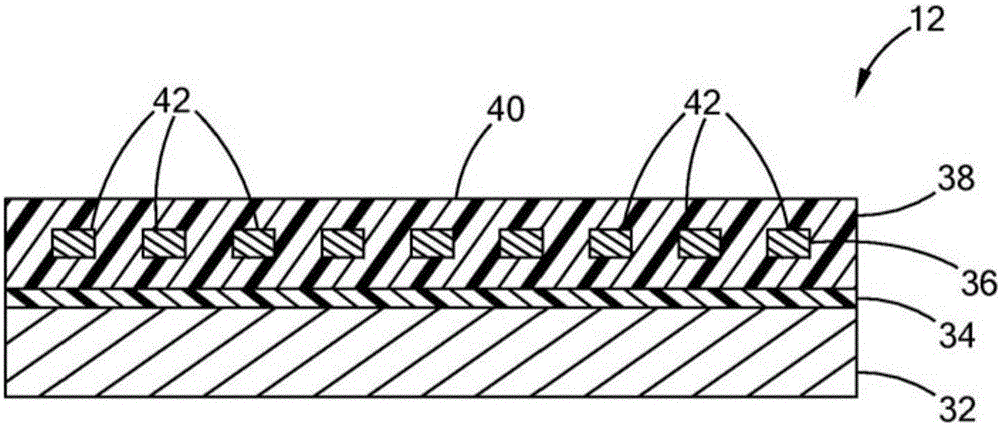

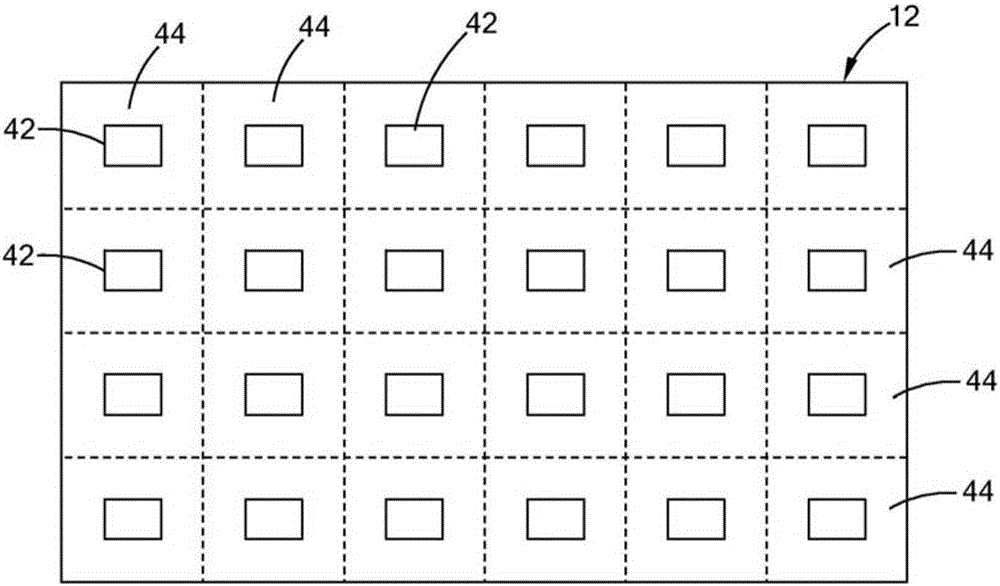

[0017] reference figure 1 The thermal imaging detection system 10 according to the teachings of the present invention includes a pixel heater 12 and a control system 14. The control system 14 includes a heater controller 16 for controlling the pixel heater 12, an imaging device 18 that acquires a thermal image of the pixel heater 12, and an analysis to determine the position of internal structures (such as defects or voids 24) in the object 26 装置20。 Device 20. The pixel heater 12 is formed as a sheet structure and is removably attached to the outer surface 28 of the object 26. The term "sheet-like" is defined herein as a plate, a generally flat sheet of material. The sheet-like structure can therefore have many overall shapes, such as rectangles, squares, circles, triangles, etc., or can be customized to fit a specific object 26. Preferably,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com